Flame-retardant polyester adhesive tape base material

A technology of flame retardant polyester and tape, applied in the field of polyester film, can solve the problems of influence of bonding ability, poor processing performance, reduced mechanical properties, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

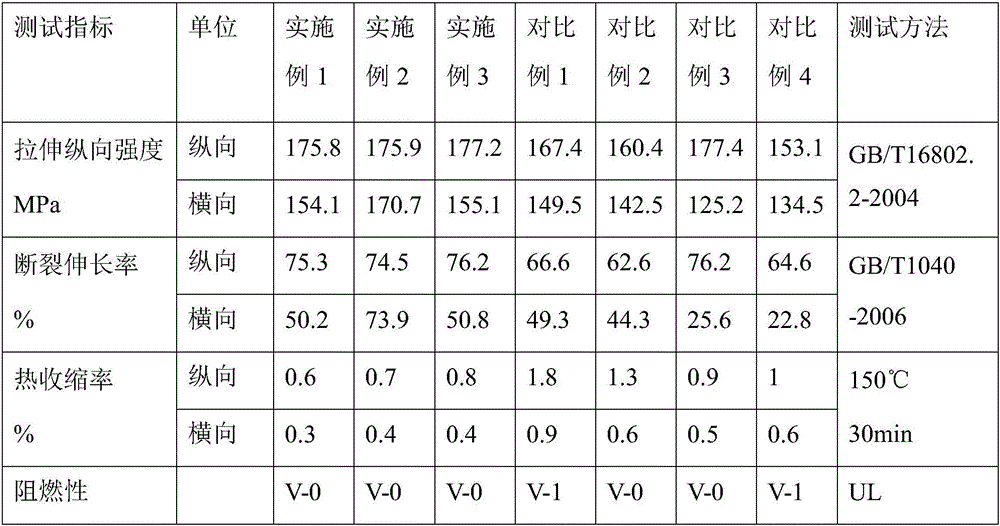

Examples

Embodiment 1

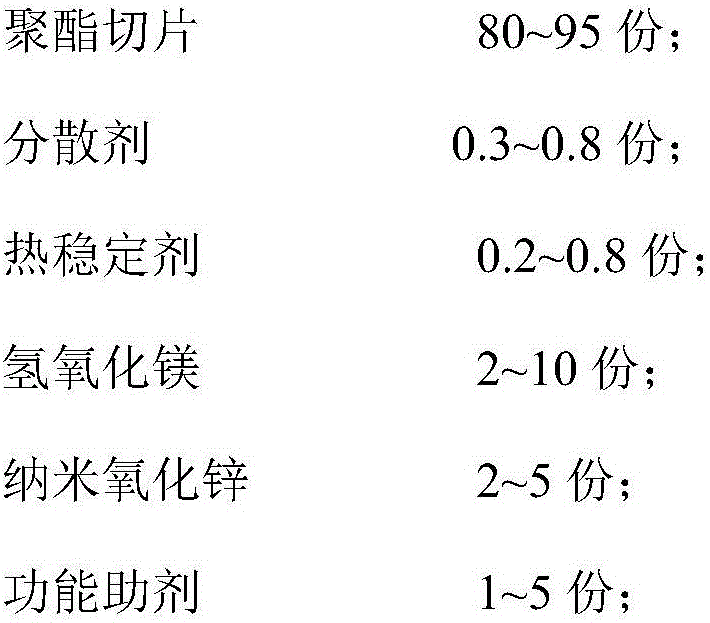

[0022] Flame-retardant polyester tape base material, including 80 parts of polyester chips, 0.3 parts of dispersant, 0.2 parts of heat stabilizer, 2 parts of magnesium hydroxide, 2 parts of nano zinc oxide, and 1 part of functional additive.

[0023] The dispersant is a mixture of stearylamide and higher alcohol (commercially available), and the ratio of the two is 8:2.

[0024] The surface of the magnesium hydroxide is treated with vinyl triethoxysilane, and the particle size is 0.5-10 μm.

[0025] The surface of the nano-zinc oxide is mechanochemically modified by stearic acid, and the particle size range is 50-100nm.

[0026] Silica adopts nano-spherical SiO with an average particle size of 10-20nm 2 .

[0027] The particle size range of functional additives is 10-100 μm, the thickness ratio of wall material and core layer is 1:18-1:22, the core layer is composite powder, and the wall material is polyester film.

[0028] The composite powder is a mixture containing titan...

Embodiment 2

[0032] Flame-retardant polyester tape substrate, including 95 parts of polyester chips, 0.8 parts of dispersant, 0.8 parts of heat stabilizer, 10 parts of magnesium hydroxide, 5 parts of nano-zinc oxide, 5 parts of functional additives, and the remaining components and contents are the same as Example 1 is the same.

Embodiment 3

[0034] Flame-retardant polyester tape substrate, including 90 parts of polyester chips, 0.6 parts of dispersant, 0.6 parts of heat stabilizer, 6 parts of magnesium hydroxide, 3 parts of nano-zinc oxide, 3 parts of functional additives, and the remaining components and contents are the same as Example 1 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com