A kind of lignin-reinforced bio-based shape-memory thermoplastic elastomer and its preparation method and application

A thermoplastic elastomer and bio-based technology, applied in the field of thermoplastic elastomers, can solve the problems of insufficient rigidity, sacrifice PLA degradability, and decrease in mechanical strength, and achieve good shape memory performance, improved shape recovery ability, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

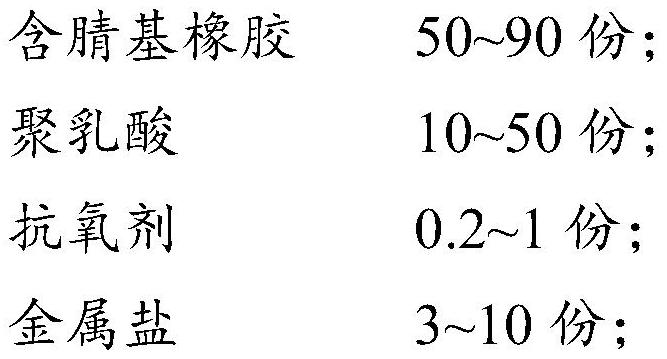

[0036] The present invention also provides the preparation method of the bio-based shape memory thermoplastic elastomer described in the above technical solution, comprising the following steps:

[0037] Mixing the nitrile-containing rubber, metal salt and lignin to obtain a masterbatch;

[0038] Mixing polylactic acid and antioxidant, plasticizing to obtain a mixture;

[0039] The masterbatch and the mixture are mixed for dynamic cross-linking to obtain a bio-based shape memory thermoplastic elastomer reinforced with lignin.

[0040] In the present invention, the nitrile-based rubber, metal salt and lignin are kneaded to obtain a master batch. In the present invention, the temperature of the kneading is preferably 30 to 60°C, more preferably 40 to 50°C; the time of the kneading is preferably 8 to 15 minutes, more preferably 10 to 13 minutes. The present invention firstly kneads the nitrile-containing rubber, metal salt and lignin, so that the lignin and the metal salt can b...

Embodiment 1

[0047] Mixing nitrile butadiene rubber (NBR), zinc chloride and lignin at 40°C for 10min to obtain a masterbatch;

[0048] The polylactic acid was dried at 70°C for 24 hours to obtain the dried polylactic acid;

[0049] An internal mixer was used, the rotation speed was set to 80 r / min, the dried polylactic acid and antioxidant 1010 were added to the internal mixer, and the mixture was uniformly plasticized at 200° C. to obtain a mixture;

[0050] The masterbatch was added to the mixture, the rotational speed in the internal mixer was set to 80 r / min, and dynamic cross-linking was carried out at 190 ° C for 10 min to obtain a bio-based shape memory thermoplastic elasticity reinforced by lignin. body;

[0051] In the present embodiment, the polylactic acid adopted is the REVODE 101 type PLA (poly-L-lactic acid) produced by Zhejiang Hisun Biomaterials Co., Ltd.; the nitrile rubber adopted is the 1043N type produced by Taiwan Nandi Chemical Industry Co., Ltd. NBR;

[0052] The...

Embodiment 2

[0057] Mixing nitrile butadiene rubber (NBR), zinc sulfate and lignin at 50°C for 10min to obtain a masterbatch;

[0058] The polylactic acid was dried at 70°C for 12 hours to obtain the dried polylactic acid;

[0059] An internal mixer was used, the rotation speed was set to 60 r / min, the dried polylactic acid and antioxidant 168 were added to the internal mixer, and the mixture was uniformly plasticized at 200 ° C to obtain a mixture;

[0060] The masterbatch is added to the mixture, the rotating speed in the internal mixer is set to 60 r / min, and dynamic crosslinking is carried out at 200 ° C for 10 min to obtain a bio-based shape memory thermoplastic elasticity reinforced by lignin. body;

[0061] In the present embodiment, the polylactic acid used is REVODE 101 type PLA produced by Zhejiang Hisun Biomaterials Co., Ltd.; the nitrile rubber used is 1043N type NBR produced by Taiwan Nandi Chemical Industry Co., Ltd.;

[0062] The parts by weight of each raw material are as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com