A thermally responsive composite self-healing coating and its preparation method

A self-healing and thermally responsive technology, used in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems affecting coating stability, low content, and decreased coating shielding performance, achieving good corrosion protection performance, Simple preparation process and the effect of wide application environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Dissolve 0.5g of polycaprolactone and 0.34g of 8-hydroxyquinoline in 18ml of dichloromethane solution, pour into a beaker filled with 100ml of polyvinyl alcohol, stir for 5min with a homogenizer, and magnetically stir for 2.5h. Put the same mass of the above solution into a plastic test tube, and centrifuge once at 2000 rpm for 5 min; once at 5000 rpm for 5 min. Pour off the test tube liquid. Place the test tube with the microspheres in the refrigerator for 30 minutes, and then vacuum freeze-dry for 24 hours.

[0034] Put 0.2g of microspheres into the mixture of 2.27g of epoxy resin and 0.2g of D230 and stir. After stirring evenly, add 0.78g of n-decylamine and continue stirring until the self-healing coating is obtained evenly. Finally, the paint is evenly coated on the base material by coating method or bar method, and then cured at 47°C for 20 hours to obtain a self-healing composite coating with uniform thickness.

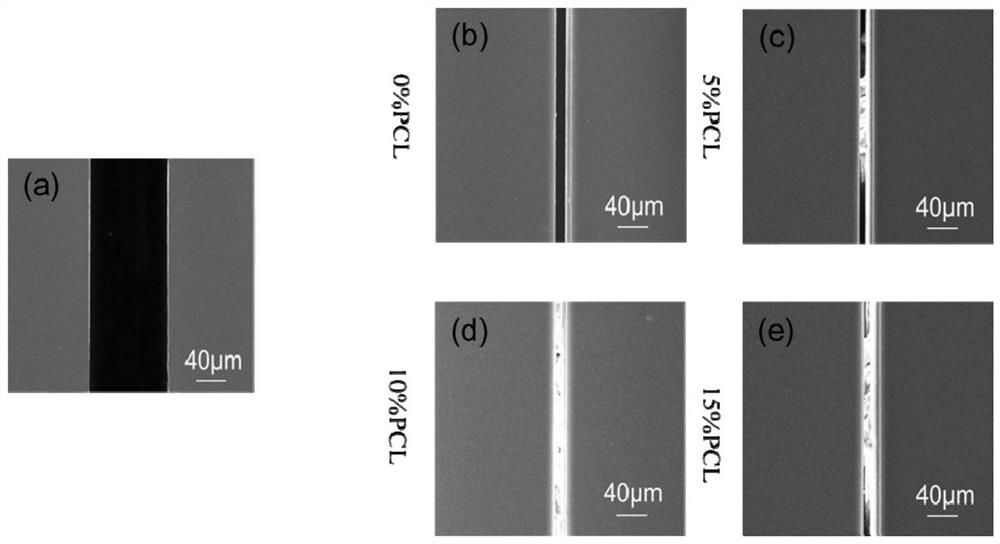

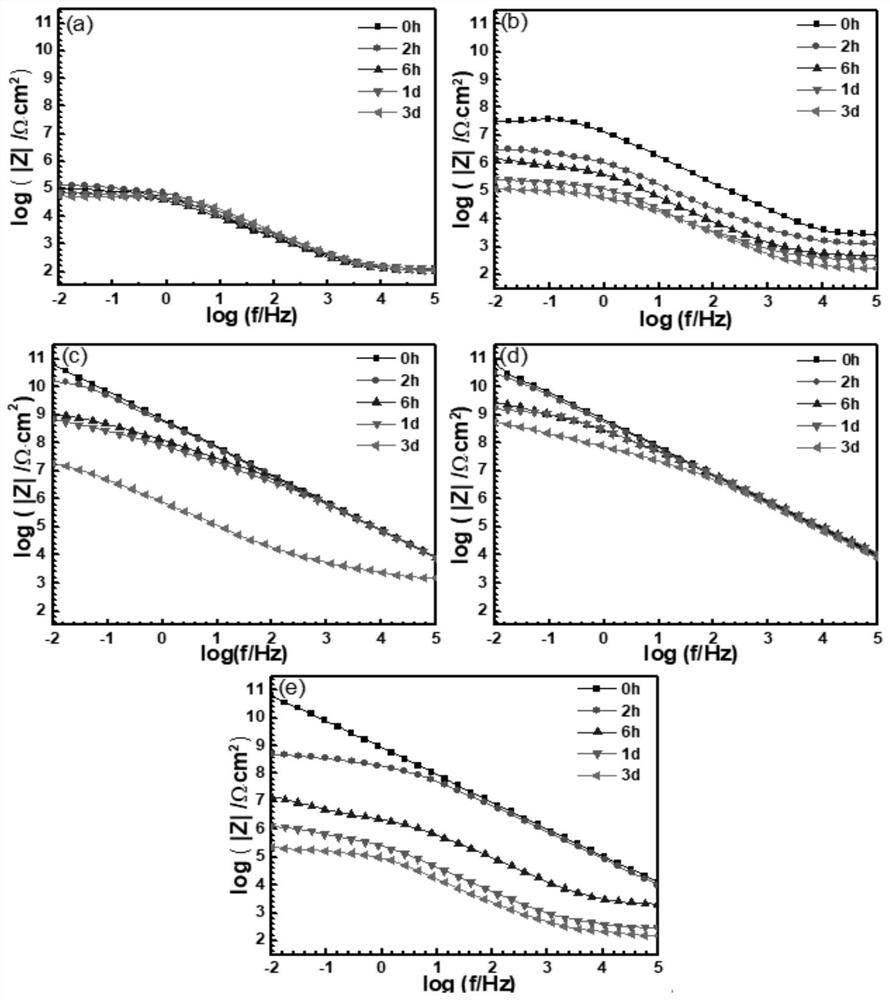

[0035] The coating is tested for self-healing, s...

Embodiment 2

[0037] Dissolve 0.5g of polycaprolactone and 0.3g of tolylbenzotriazole in 20ml of dichloromethane solution, pour into a beaker filled with 100ml of polyvinyl alcohol, stir with a homogenizer for 5min, and magnetically stir for 2.5h. Put the same mass of the above solution into a plastic test tube, and centrifuge once at 2000 rpm for 5 min; once at 5000 rpm for 5 min. Pour off the test tube liquid. Place the test tube with the microspheres in the refrigerator for 30 minutes, and then vacuum freeze-dry for 24 hours.

[0038] Put 0.17g of microspheres into the mixture of 2.27g of epoxy resin and 0.25g of D230 and stir. After stirring evenly, add 0.75g of n-decylamine and continue stirring until the self-healing coating is uniformly obtained. Finally, the paint is uniformly coated on the base material by coating method or bar method, and then cured at 52°C for 24 hours to obtain a self-healing composite coating with uniform thickness.

[0039] The coating is tested for self-hea...

Embodiment 3

[0041] Dissolve 0.5g of polycaprolactone and 0.35g of benzotriazole in 22ml of dichloromethane solution, pour into a beaker filled with 100ml of polyvinyl alcohol, stir with a homogenizer for 5min, and magnetically stir for 2.5h. Put the same mass of the above solution into a plastic test tube, and centrifuge once at 2000 rpm for 5 min; once at 5000 rpm for 5 min. Pour off the test tube liquid. Place the test tube with the microspheres in the refrigerator for 30 minutes, and then vacuum freeze-dry for 24 hours.

[0042] Put 0.34g of microspheres into the mixture of 2.27g of epoxy resin and 0.22g of D230 and stir. After stirring evenly, add 0.7g of n-decylamine and continue stirring until the self-healing coating is uniformly obtained. Finally, the paint is evenly coated on the base material by coating method or bar method, and then cured at 50°C for 30 hours to obtain a self-healing composite coating with uniform thickness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com