Force-induced responsive cross-linked polymer

A technology of cross-linked polymers and polymers, applied in the field of mechanoresponsive polymers, can solve problems that cannot meet the needs of human social development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

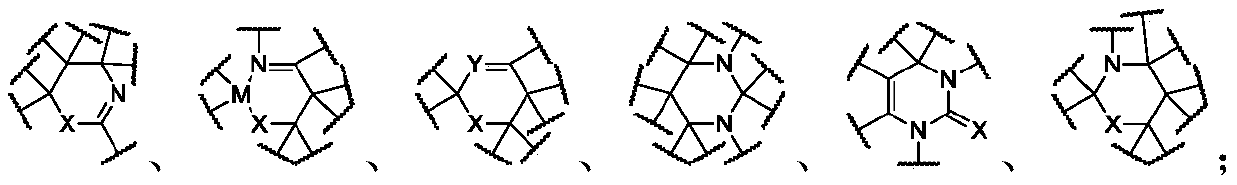

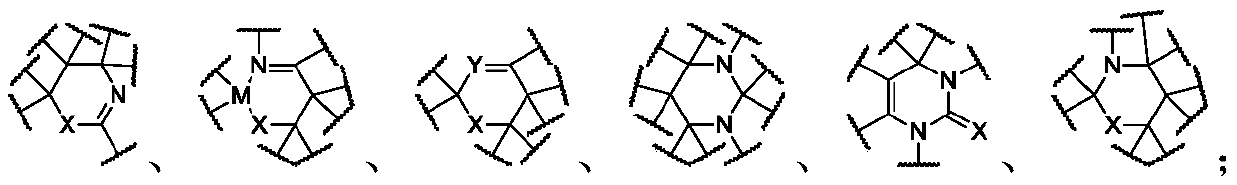

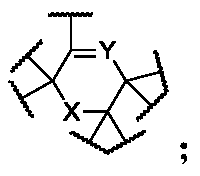

Image

Examples

preparation example Construction

[1798] In the preparation process of the polymer, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam it.

[1799] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the polymer to make it a uniform foam, and then through physical or Chemical changes shape it into foam. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[1800] Wherein, the physical foaming method is to use physical principles to realize the foaming of the polymer during the preparation of the polymer, which includes but is not limited to the following methods: (1) inert gas foaming method, that is, under pressure Under normal circumstances, the inert gas is pressed into the molten polymer or pasty material, and then the pressure is reduced and the te...

Embodiment 1

[1812]

[1813] With 0.3 molar equivalents of compound (a), 0.3 molar equivalents of pentaerythritol, and 2 molar equivalents of carboxy-terminated polytetrahydrofuran with a molecular weight of 5000, dichloromethane was used as a solvent, and 0.01 molar equivalents of N,N-diisopropylcarbodiethylene Amine, 0.01 molar equivalent of diphenyl-4-phenylthiophenylsulfonium salt, make the reaction system stir and react at room temperature for 24h, remove the solvent, pour the reactant into a specific mold, and prepare a polymer film. In this example, under the action of tensile force, the prepared polymer film changed from non-fluorescence to blue fluorescence under ultraviolet light. Taking advantage of this property, it can be used as a stress warning material .

Embodiment 2

[1815]

[1816] Weigh 0.3 molar equivalent of compound (a), 0.1 molar equivalent of aluminum-containing catalyst compound (c) and 1 molar equivalent of racemic lactide into a reactor, use toluene as solvent, and heat to 70°C under nitrogen atmosphere , stirred for 4 h, then cooled in ice water for 10 min, then cooled in ice for 10 min, then added 0.3 molar equivalent of glycerol, and heated at 70 ° C for 120 h, the resulting polymer was precipitated in cold petroleum ether, and The filtered product was swelled in ethanol solvent for 24 h to prepare a polymer organogel. Under the action of stress, the force-sensitive groups of the polymer will open rings, which improves the toughness of the organic gel, and the gel will self-degrade under certain conditions, and can be used as a drug wrapping material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com