Heat exchanger and associated heat exchange system for a vehicle

A heat exchange system and heat exchanger technology, applied in the field of heat exchange systems, can solve the problems of limiting the size of the system, complex manufacturing and implementation of the heat exchange system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

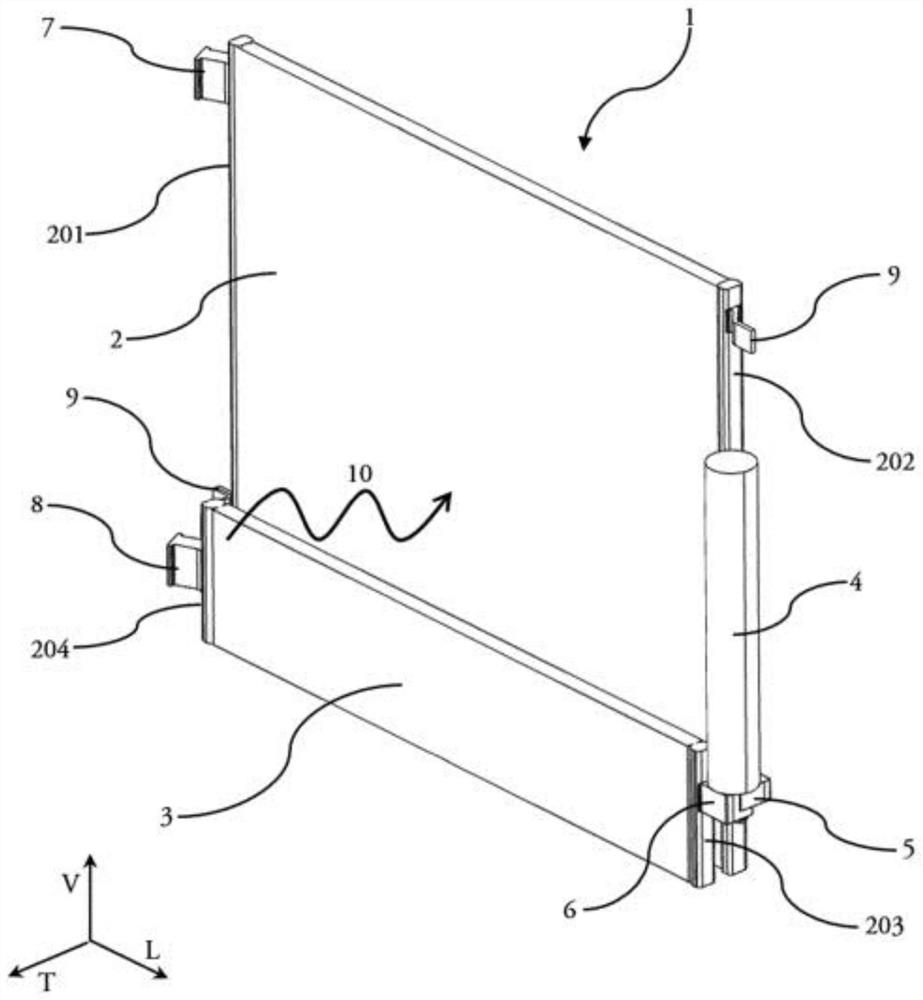

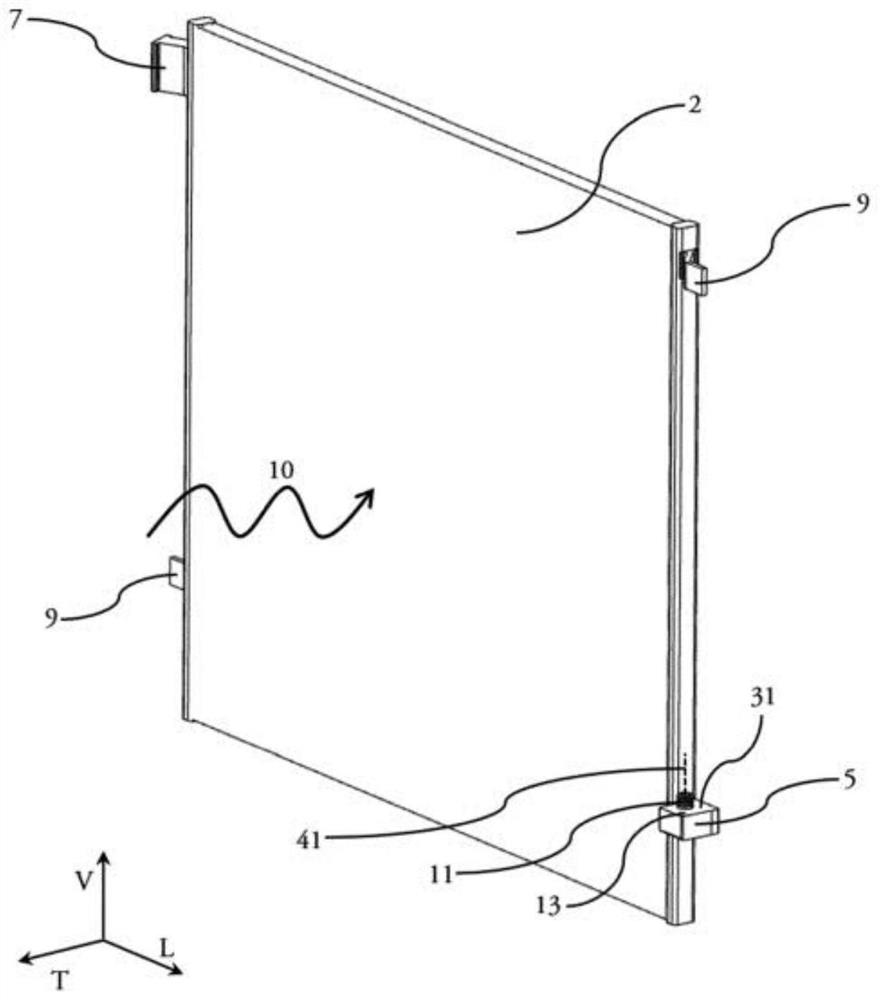

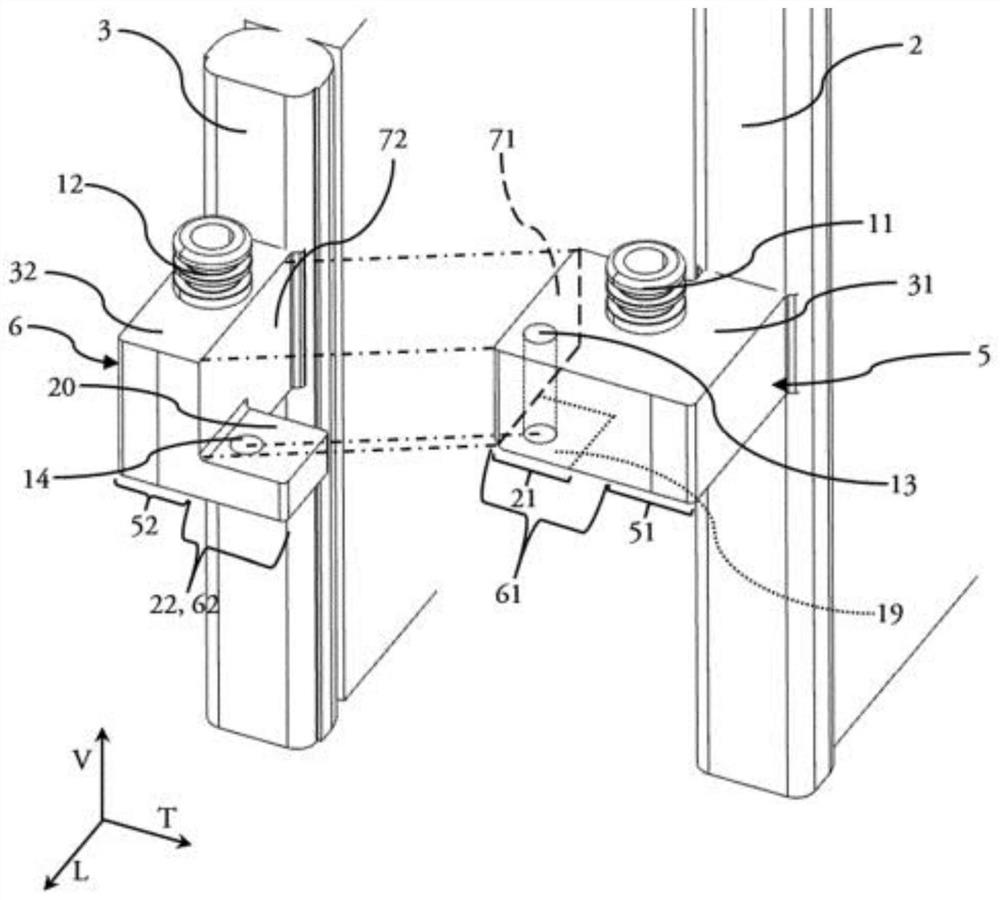

[0040] For the clarity of the detailed description of the connecting flanges, the LVT frame of reference will represent the orientation of the heat exchange system according to the invention. The longitudinal direction L and the vertical direction V correspond to axes parallel to the two intersecting straight lines defining the elongate plane of the heat exchanger according to the invention, the transverse direction T corresponds either to an axis perpendicular to one of the directions L or V, or Corresponds to the axis parallel to the airflow forced through the heat exchange system.

[0041] In addition, the terms "first" and "second" mentioned in the description have no quantitative or ordering meaning, but are only used to distinguish certain elements that appear repeatedly in the present invention. An element present in duplicate in the present invention but not introduced by the term "first" or "second" designates equivalently one or the other element in duplicate.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com