Cabinet door sealing mechanism and low-temperature automatic warehouse

A technology of sealing mechanism and cabinet door, which is applied to biochemical instruments, biochemical cleaning devices, preservation of human or animal bodies, etc. problems, to achieve the effect of reducing energy consumption, simple control and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

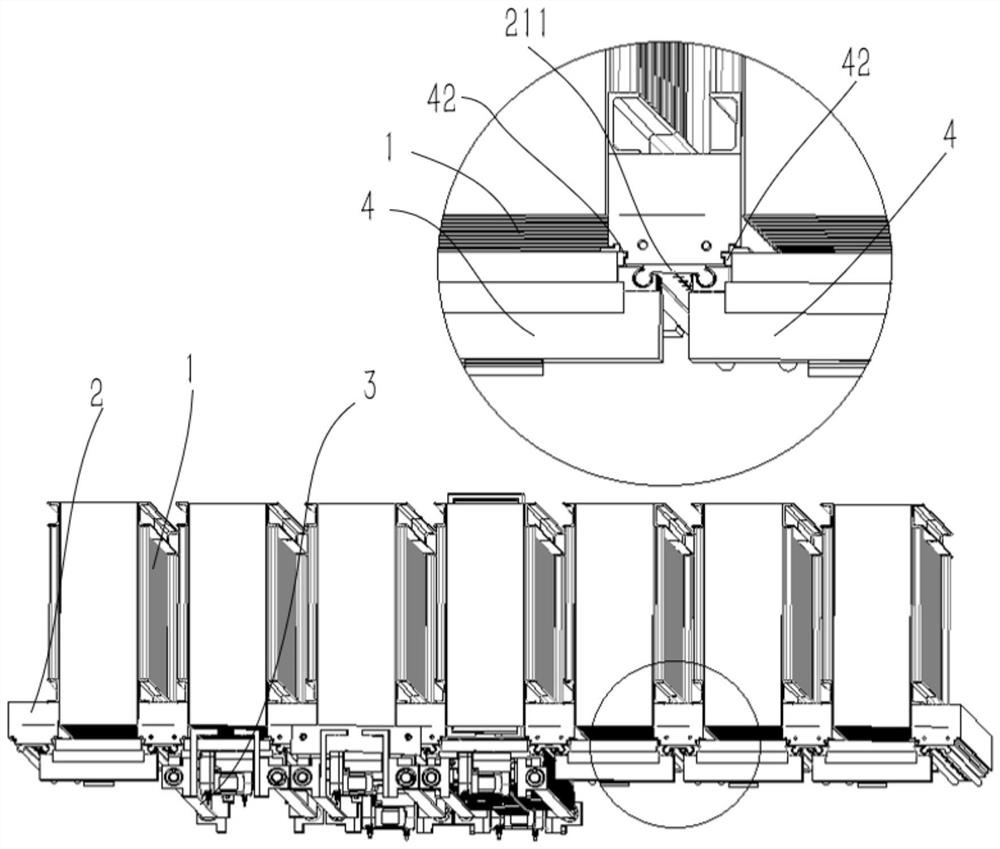

[0044] In this embodiment, the contact position between the rear end of the airtight door 4 and the cabinet door frame 21 is a cuboid structure, and the bottom and side surfaces of the cuboid structure are respectively provided with a sealing strip 42 with an "L"-shaped cross section. Close to the setting, the cabinet door frame 21 is provided with a labyrinth groove 212 matching the "L" shaped sealing strip 42 .

[0045] The airtight door 4 includes a door panel 41, and the front end of the door panel 41 is provided with a door opening mechanism 43 for driving the airtight door 4 up and down by other mechanisms. Manipulators can be set to drive the airtight door 4 up and down. In the process of opening the door, wear may occur between the airtight doors 4, and guard plates 44 are set between adjacent airtight doors 4 to reduce the wear of the airtight doors 4.

Embodiment 2

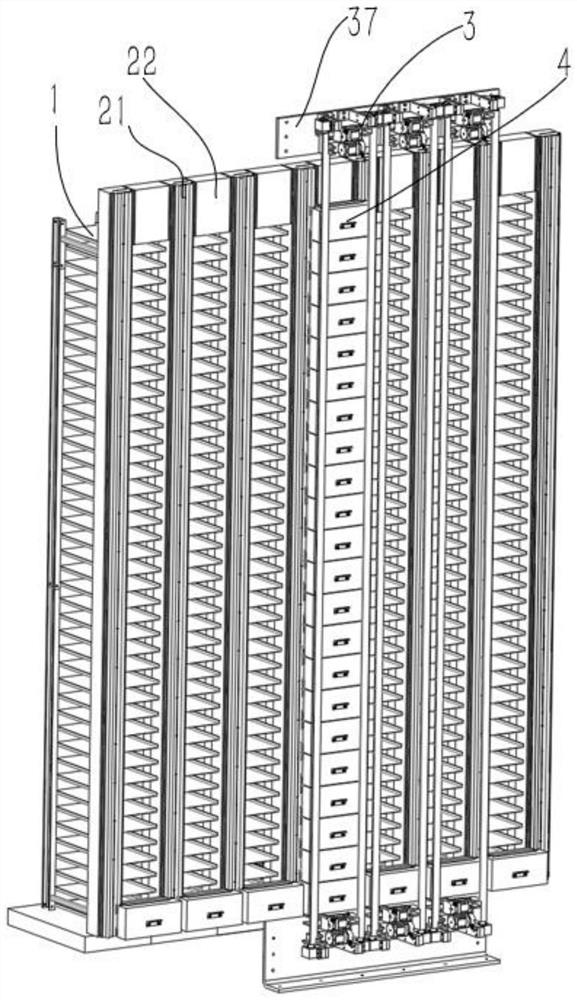

[0047] In this embodiment, the locking mechanism 3 includes a locking pressure plate 31, a bearing seat 32, a connecting seat 33, an electric push rod 34, a rotating shaft 35, an eccentric mechanism 36, and a mounting seat 37, wherein the outer side of the sealing door 4 is provided with a pair of sealing doors. 4. The locking pressing plate 31 that plays a pressing role; the two ends of the locking pressing plate 31 are equipped with an eccentric mechanism 36; one end of the eccentric mechanism 36 is connected to the bearing seat 32 through the rotating shaft 35, and the other end is connected to the electric push rod 34. Pushed by the push rod 34 , the locking pressing plate 31 can rotate around the rotating shaft 35 to realize the compression of the airtight door 4 . The electric push rod 34 and the bearing seat 32 are connected to the mounting seat 37 through the connecting seat 33 .

[0048] In this example, refer to Figure 7 , Figure 8 , the structure of the eccentri...

Embodiment 3

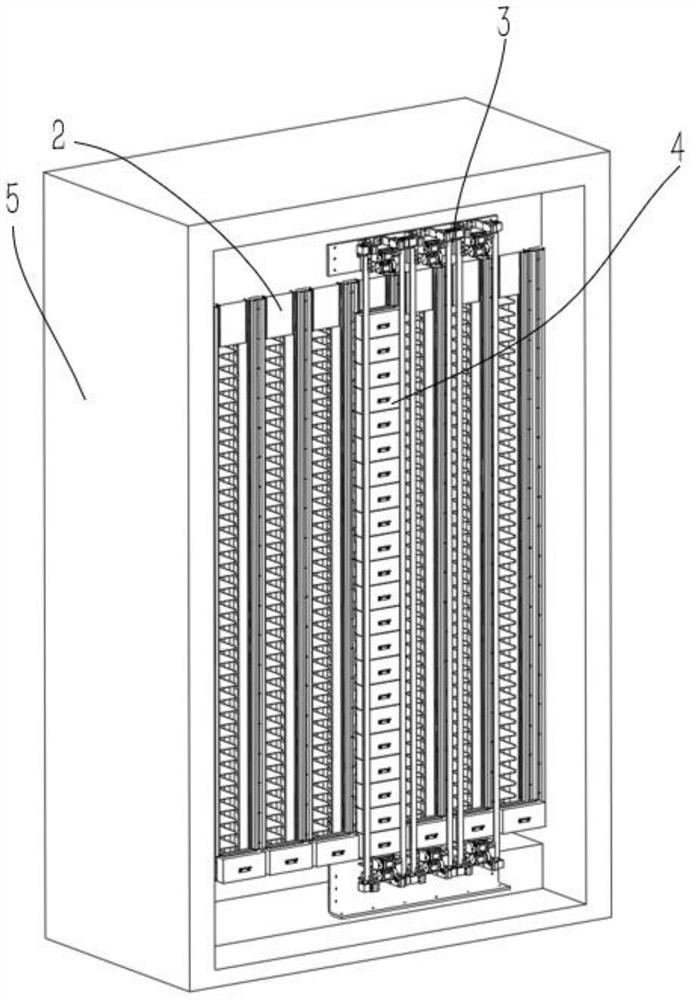

[0050] In this embodiment, a low-temperature automated warehouse 5 includes a cabinet door sealing mechanism, the storage cabinet 1 is arranged inside the low-temperature automated warehouse 5, and the cabinet door mechanism 2 is connected and fixed with the low-temperature automated warehouse 5 through a connecting component; the locking mechanism 3 is provided The upper and lower mounting bases 37 are connected to the low-temperature automated warehouse 5 through the mounting bases 37 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com