An Ultrasonic Transducer Applied to Water Meter

An ultrasonic and transducer technology, applied in the field of ultrasonic transducers, can solve the problems of glue performance degradation, glue curing wait, ultrasonic transducer performance attenuation, etc., to reduce the difficulty of matching, avoid performance degradation, and improve assembly efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

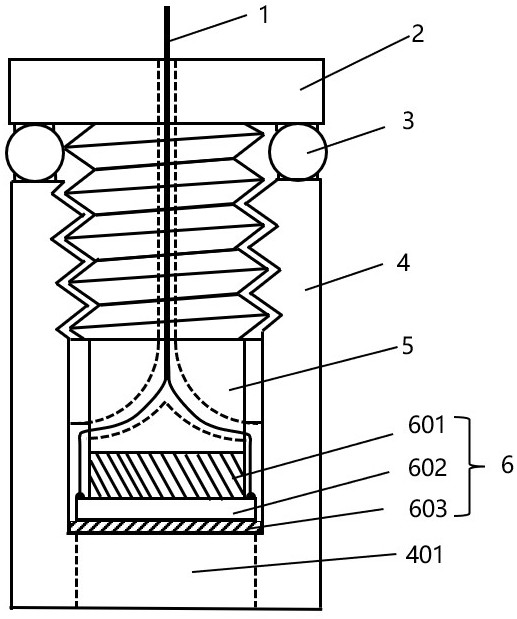

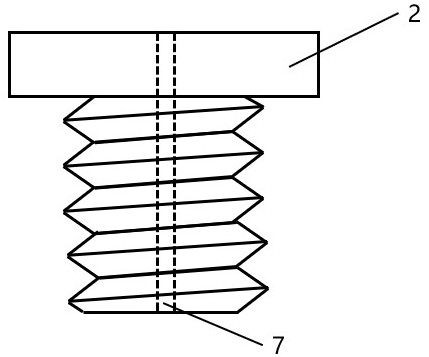

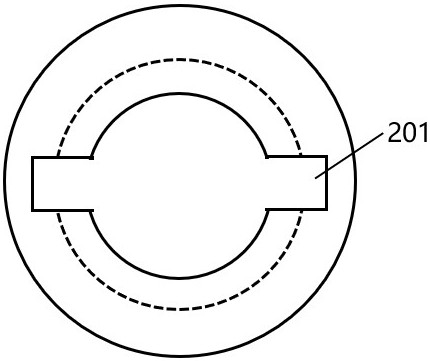

[0025] like figure 1 As shown, an ultrasonic transducer applied to a water meter includes an ultrasonic transducer housing 4 (such as Figure 7 shown), adjusting screw 2 (such as figure 2 , image 3 shown), sealing rubber ring 3, pressure block 5 (such as Figure 4 , Figure 5 shown), sensor unit 6 (eg Image 6 shown), shielded cable 1;

[0026] The sensor unit 6 includes a backing layer 601, a piezoelectric ceramic 602, and a connection layer 603;

[0027] The connection relationship is as follows: the adjustment screw 2 is located at the upper end of the ultrasonic transducer shell 4, the adjustment screw 2 and the ultrasonic transducer shell 4 are connected by a sealing rubber ring 3, and inside the ultrasonic transducer shell 4 from top to bottom sequentially For the pressure block 5, the backing layer 601, the piezoelectric ceramics 602, and the connection layer 603, each part is connected by applying compressive stress through the adjustment screw 2, and the shiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com