Laminated steel pipe magnet yoke type uniform magnetization device

A uniform magnetization and laminated technology, applied in the direction of magnetic objects, circuits, electrical components, etc., can solve the problems of inconsistency in detection signals, increasing the technical difficulty of defect quantitative evaluation, and inconsistency in magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

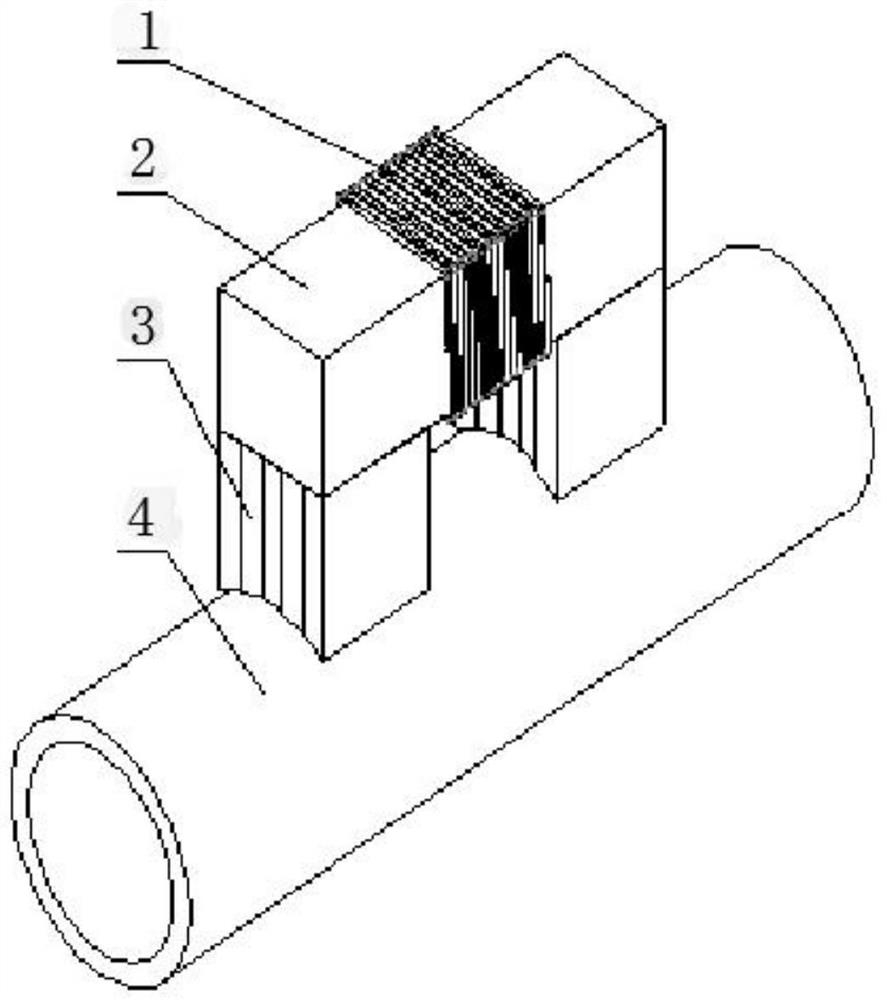

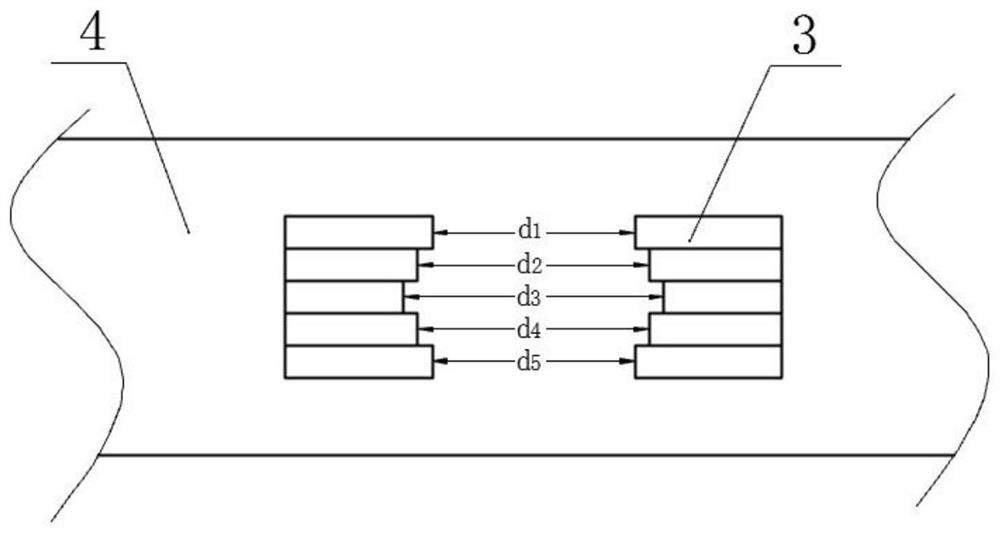

[0019] Such as figure 1 with figure 2 As shown, a laminated steel pipe yoke-type uniform magnetization device includes a coil 1, an iron core 2 and a laminated yoke 3. The coil 1 is evenly wound on the outside of the iron core 2, and the two ends of the coil 1 are connected to the power line Connection, the lower end of the laminated yoke 3 abutting against the surface of the steel pipe 4 is arc-shaped, and the diameter of the arc is larger than the outer diameter of the steel pipe 4. The laminated yoke 3 is connected by five steel plates, and the steel plates on the front and rear sides With respect to the mirror image symmetrical setting of the middle steel plate, there are two laminated yokes 3, and the distances between the corresponding steel plates of the two laminated yokes 3 are respectively d1, d2, d3, d4 and d5, and d1=d5

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap