Box body positioning locking, overturning and door opening and closing mechanism for horizontal-in and horizontal-out vertical pressing station

A technology for positioning and locking and opening the door mechanism, applied in the direction of presses, applications, household appliances, etc., can solve the problems of many docking points, unadjustable distance between boxes, small lifting stroke, etc., to reduce the turning radius, save the cost of civil engineering, The effect of reducing the lifting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

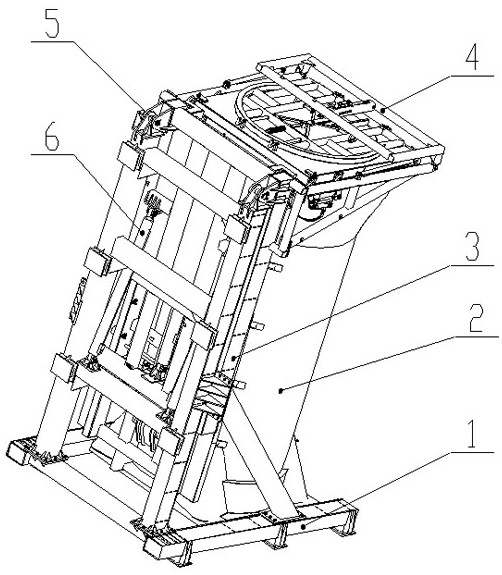

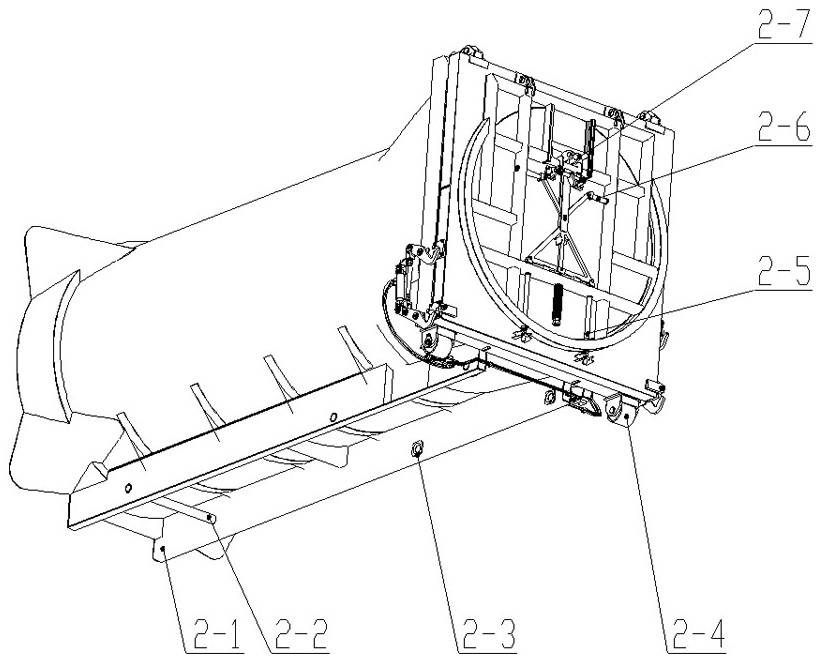

[0022] Such as Figure 1 to Figure 7 The box positioning and locking, turning and opening and closing mechanism for the vertical press station shown in the horizontal entry and exit is characterized in that it includes a fixing frame 1, a turning frame 3, a turning cylinder 6, a door opening mechanism 4 and a connecting pin 5. The overturning frame 3 is connected and fixed on the fixed frame 1, the fixed end of the overturning oil cylinder 6 is installed on the fixed frame 1, the telescopic end of the overturning oil cylinder 6 is connected on the overturning frame 3, and the box body 2 is fixed on the overturning frame 3 , the door opening mechanism 4 is fixed on the flip frame 3 to control the rear door of the box body 2;

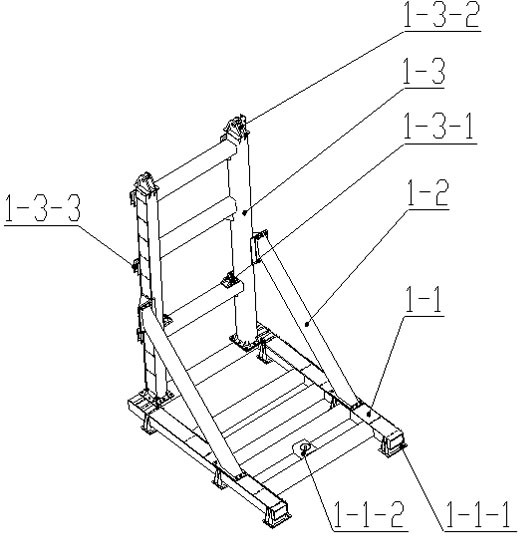

[0023] Described fixed frame 1 comprises fixed frame bottom frame 1-1, fixed frame vertical frame 1-3 and fixed frame oblique support 1-2, and the bottom of fixed frame bottom frame 1-1 is provided with the anchor bolt fixed with civil foundation. Underf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com