Pressure control valve

A pressure-regulating, adjustable technology, applied in the field of pressure-regulating valves, which can solve problems such as high manufacturing and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

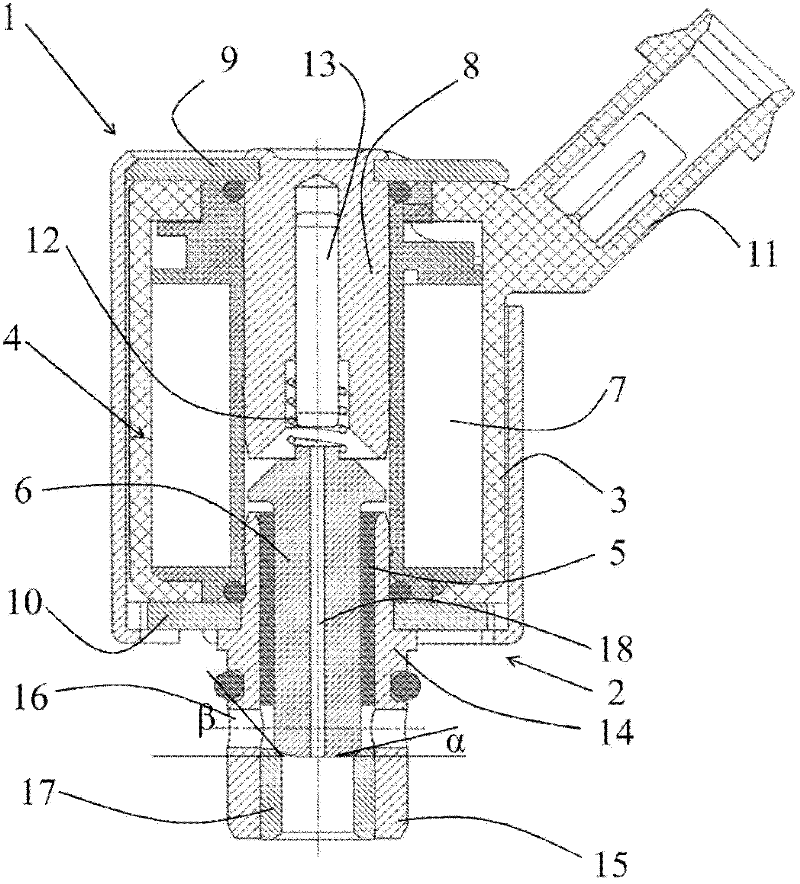

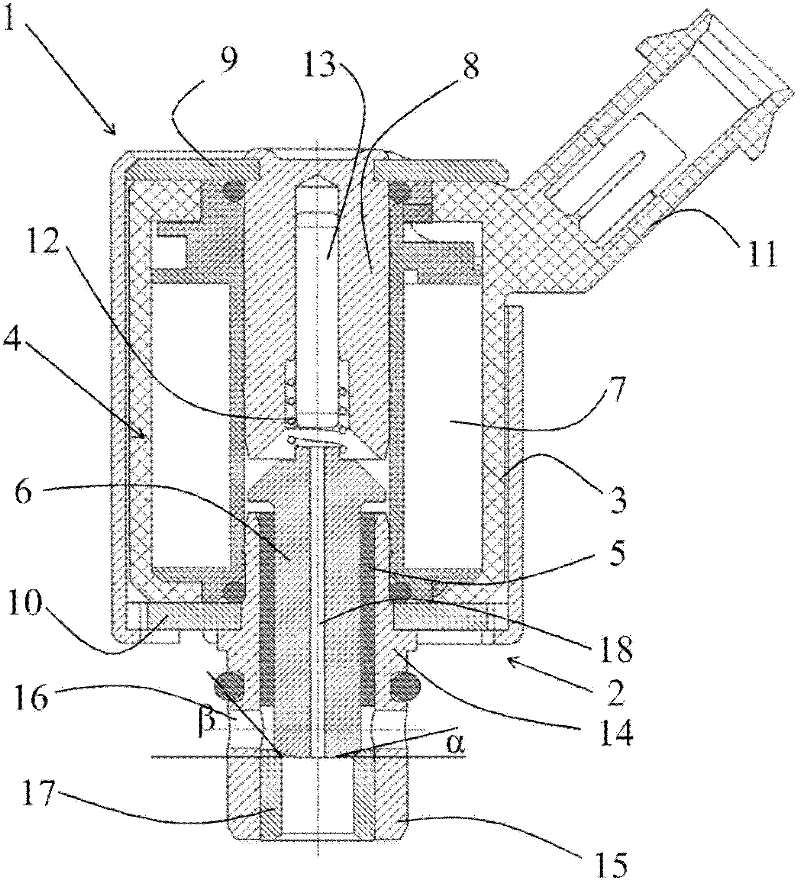

[0012] The regulating valve 1 according to the invention has a housing 2 which is basically designed as a two-part housing. The upper part 3 has an electromagnetic drive unit 4 which acts on an armature 6 arranged in an axially displaceable manner in a bearing 5 . The electromagnetic drive 4 basically comprises a coil 7 , a core 8 and a magnetic flux guide comprising a return plate 9 and a yoke 10 . The housing made of plastic also has a plug 11 for controlling the pressure control valve. The core 8 is in this case clamped within the upper part 3 .

[0013] The electromagnetic driver 4 acts on the armature 6, which in this case serves as the valve stem and valve closing member of the on / off valve. The armature 6 is here pretensioned in the closed position relative to the core 8 by means of the spring 12 . The spring 12 is guided by a peg 13 which, in the installed state, is arranged adjustably in the core and at the same time serves as an upper stop element for the armature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com