Pick-and-place device of outsole pressing mold

A pick-and-place device and mold technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems that automatic pick-and-place molds cannot be realized, and achieve the effect of automatic access to molds and avoid low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

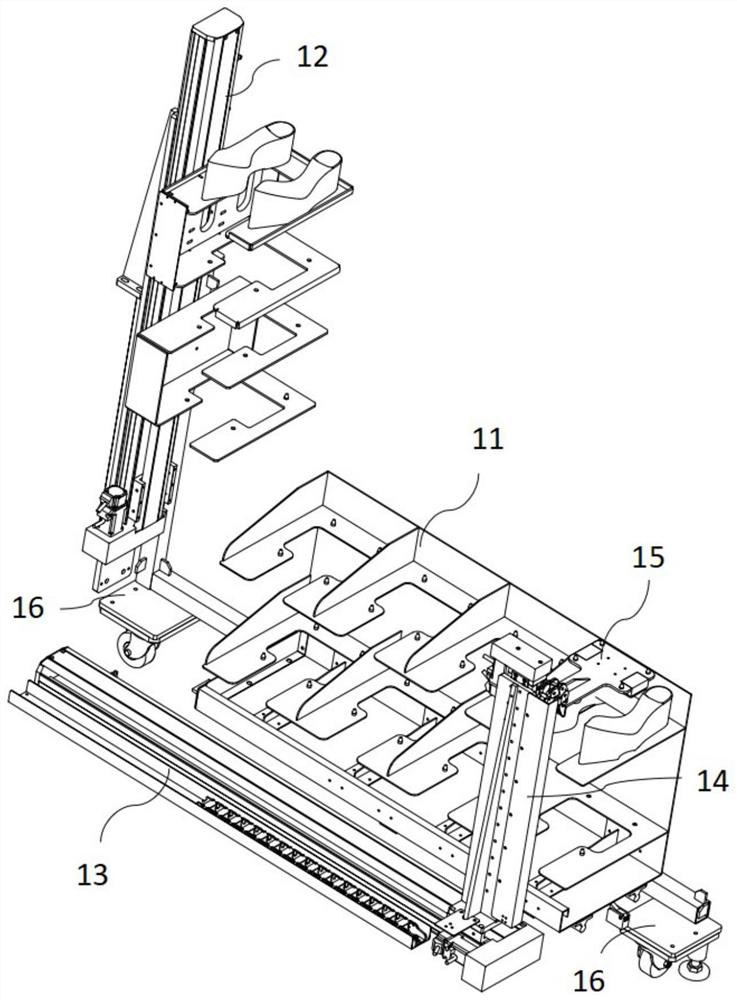

[0025] see figure 1 and figure 2 As shown, it is a first specific embodiment of a pick-and-place device for pressing a large bottom mold of the present invention, including:

[0026] Outsole mold storage rack 11, outsole mold storage rack 11 is provided with a plurality of mold storage units;

[0027] The first linear module 12, the first linear module 12 is vertically arranged and arranged side by side with the outsole mold storage frame 11, and at least one mold storage unit is provided on the slide table of the first linear module 12;

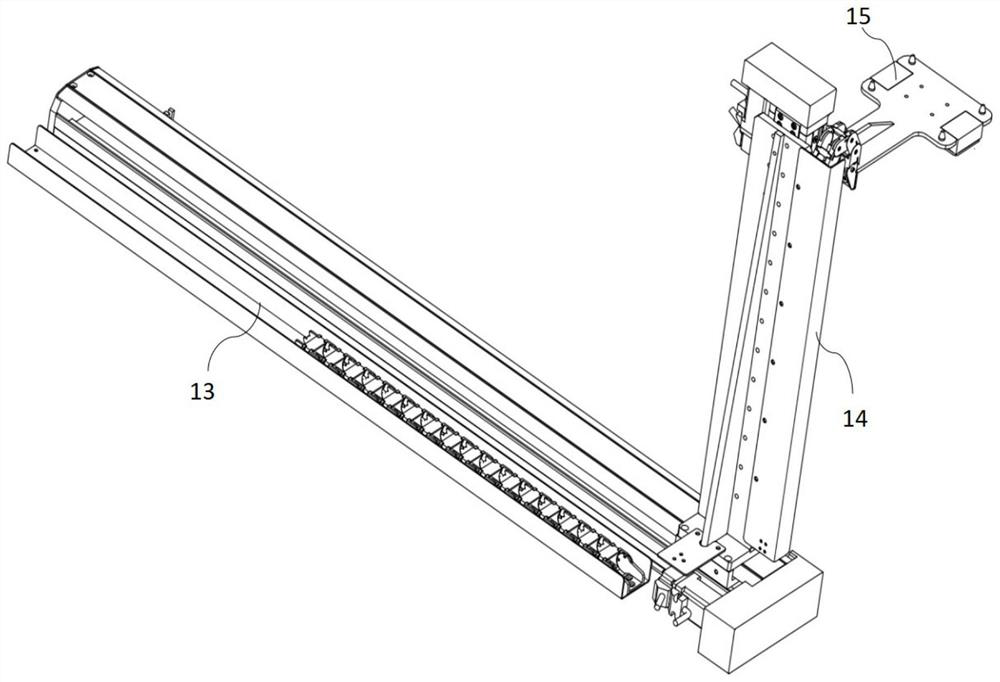

[0028] The second linear module 13, the second linear module 13 is arranged in parallel on one side of the big bottom mold storage frame 11 mould;

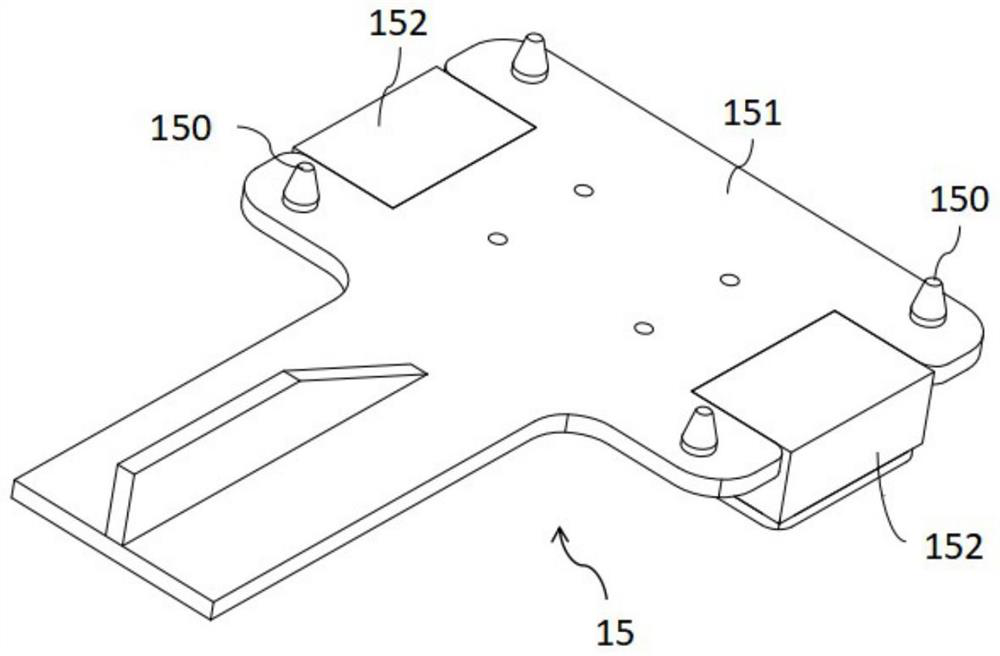

[0029] The third linear module 14, the third linear module 14 is vertically arranged on the slide table of the second linear module 13, and a mold pick-and-place mechanism 15 is fixedly arranged on the slide table of the third linear module 14.

[0030] The purpose of the mold pick-and-place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com