New energy lithium battery puncturing equipment

A lithium battery and new energy technology, applied in the field of new energy lithium battery puncture equipment, can solve the problems of easy harm and trouble to people, and achieve the effect of avoiding damage from explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

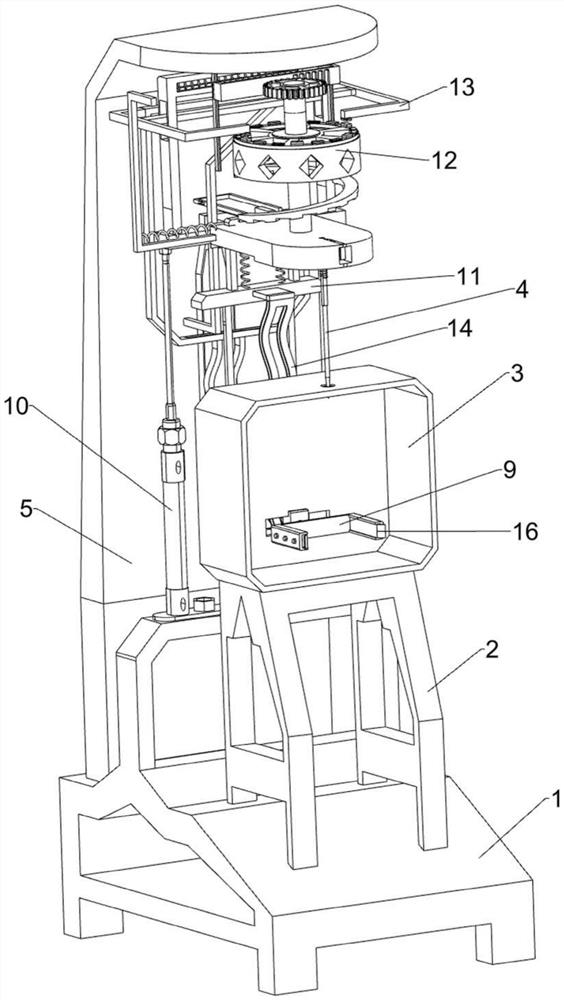

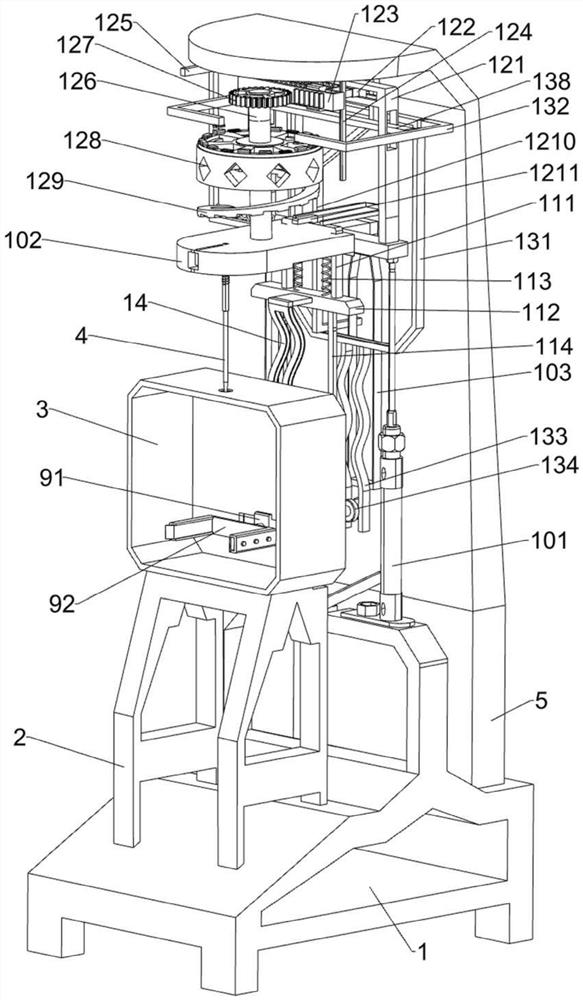

[0038] A new energy lithium battery puncture device, including a base 1, a support frame 2, a frame body 3, a steel needle 4, an L-shaped plate 5, an L-shaped clamp plate 6, a fixing block 7, a torsion spring 8, a placement mechanism 9 and a drive Institution 10, see Figure 1-Figure 7 As shown, an L-shaped plate 5 is installed in the middle of the top rear side of the base 1 by welding, and a fixed block 7 is installed on the front side of the top middle of the base 1 by welding, and the upper left and right sides of the fixed block 7 are rotated An L-shaped clamping plate 6 is connected, and a torsion spring 8 is connected between the lower part of the left and right sides of the L-shaped clamping plate 6 and the inner, left and right sides of the fixed block 7 respectively. The frame 3 is installed on the top by welding, and the lower part of the rear side of the frame 3 is equipped with a placement mechanism 9. The operator can place the new energy lithium battery on the p...

Embodiment 2

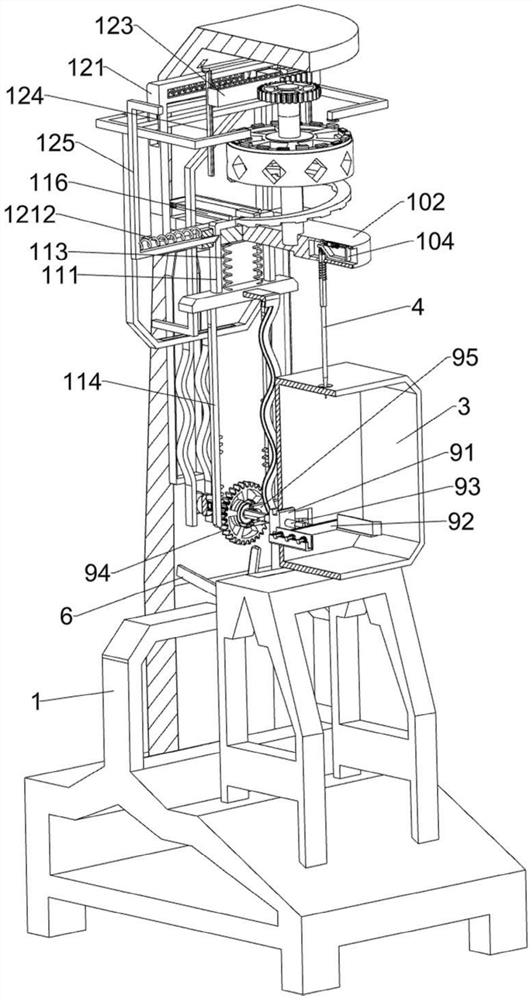

[0045] On the basis of Embodiment 1, an adjustment mechanism 11 is also included. The adjustment mechanism 11 includes an n-type plate 111, a guide rail 112, a first spring 113, a missing rack 114, a second spring 115 and a limit plate 116. Please refer to figure 1 , figure 2 , image 3 and Figure 10 As shown, an n-type plate 111 is slidingly connected in the middle of the rear of the movable plate 102, and a guide rail 112 is installed between the two ends of the bottom of the n-type plate 111 by welding, and the outer top of the guide rail 112 is connected to the rear side of the movable plate 102 bottom. The first spring 113 is symmetrically connected between the left and right, and there are two missing racks 114 slidingly placed in the guide rail 112. When the missing racks 114 move downward, the missing racks 114 can drive the column gear 94 to rotate, and the left and right two A second spring 115 is installed between the top of the outer surface of the side missing...

Embodiment 3

[0052] On the basis of Embodiment 1 and Embodiment 2, a wave guide plate 14 and a trigger lever 15 are also included, please refer to figure 1 , figure 2 , Figure 11 and Figure 12 As shown, a trigger lever 15 is installed in the left and right sides of the Liuling pole 93 through welding connection, and a wave guide plate 14 is installed in the middle of the outer front side of the guide rail 112 through welding. The trigger lever 15 is located in the wave guide plate 14. When When the wave guide plate 14 moves, the wave guide plate 14 can drive the trigger lever 15 to move back and forth.

[0053] Also include rubber plate 16, guide rod 17 and the seventh spring 18, please refer to figure 1 and Figure 14 As shown, the U-shaped plate 92 is evenly spaced on the left and right sides of the slide type and connected with three guide rods 17, and the inner ends of the three guide rods 17 on the left and the inner ends of the three guide rods 17 on the right are all connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com