Automatic device for material feeding

An automatic device and material technology, applied in packaging, conveyor objects, loading/unloading, etc., can solve the problems of difficult to control feeding speed, large deviation and fluctuation, product yield and quality cannot be further improved, etc., and achieve stable parking. , The effect of preventing clogging and easy control of feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

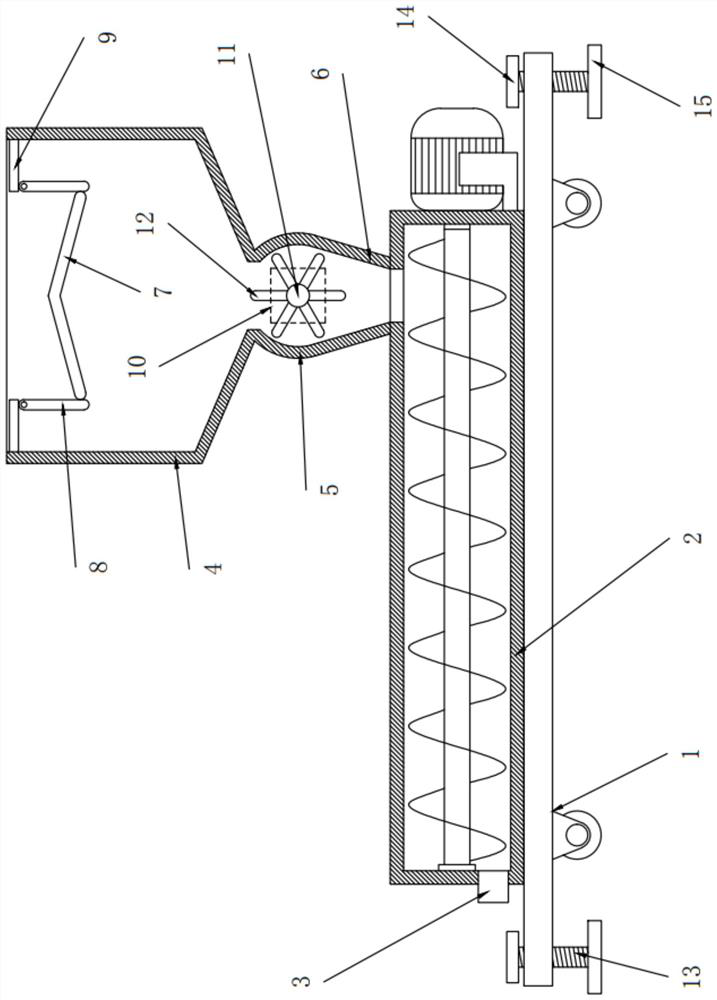

[0016] An automatic device for material feeding, comprising a mobile base 1 and an auger conveyor 2 installed and fixed on the upper side of the mobile base 1, the auger conveyor 2 is existing equipment, and is connected to an external power supply and a control switch, said The upper right side of the auger conveyor 2 is provided with a stuffing bucket, and the left end is provided with a discharge pipe 3, and the stuffing bucket is fixed on the mobile base 1 through a support frame. The filling hopper includes a bucket body 4 , a bucket neck 5 and a feeding pipe 6 which are integrally formed. The four corners of the mobile base 1 are respectively provided with gripping structures. Specifically, the gripping structures include a threaded rod 13 that runs through the mobile base 1 and is threadedly connected with the mobile base 1 , and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com