Cooking plate, cooking equipment and cooking pot

A panel and panel body technology, which is applied in the field of kitchen equipment, can solve the problems of limited range of use of induction cooker, unrealizable principle problems, and large gap in thermal expansion coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

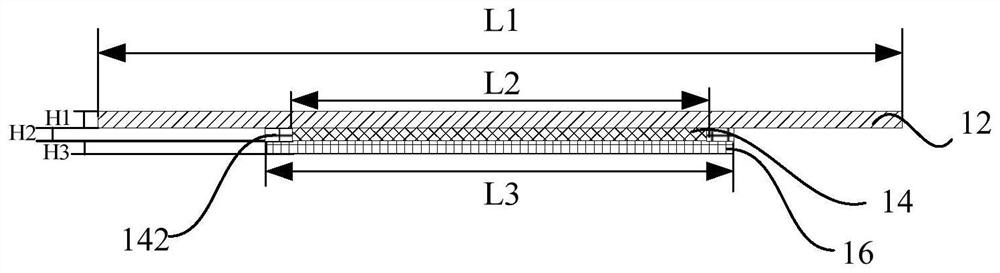

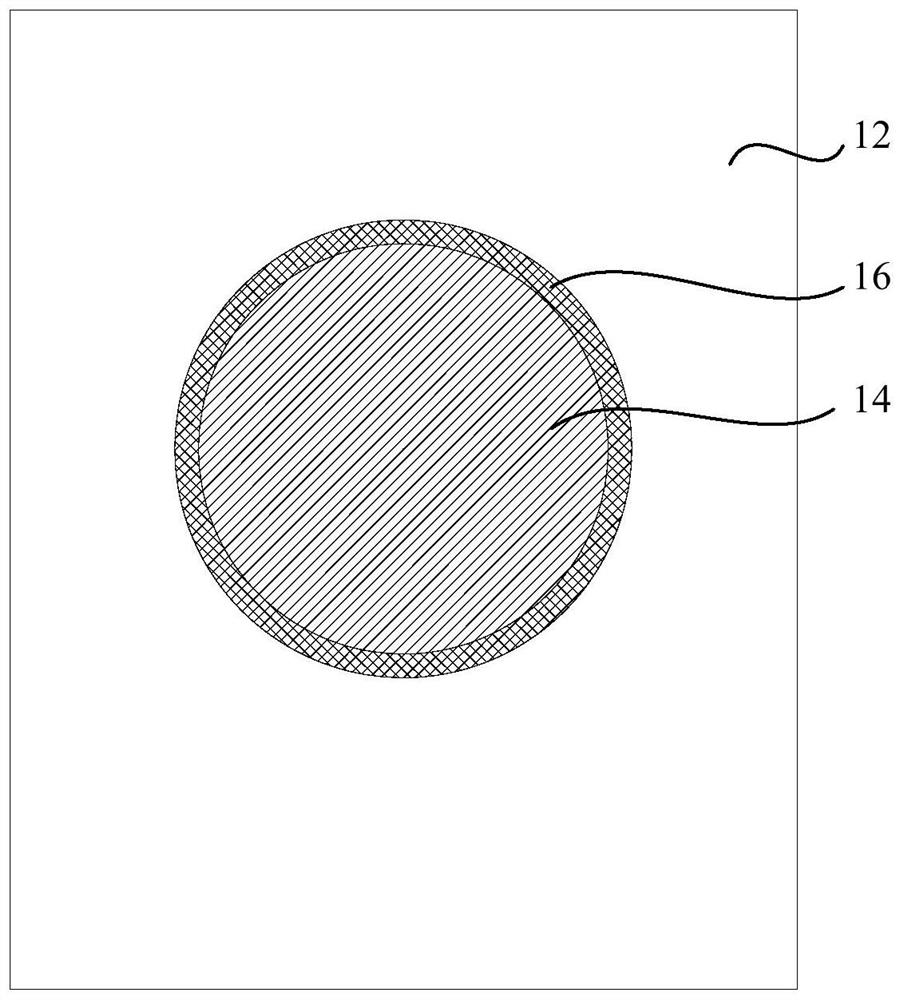

[0102] like figure 1 and figure 2 As shown, a cooking plate 1 is proposed according to one embodiment of the present invention, comprising a plate body 12, a magnetically permeable heating layer 14 and a protective structure 16 arranged in sequence. Between the structures 16, the contact area with the air can be reduced, and it can work reliably at a higher temperature for a long time.

[0103] Specifically, when the magnetically conductive heating layer 14 senses an alternating magnetic field perpendicular to itself, it will cut the magnetic field to generate eddy currents on the surface of the magnetically conductive heating layer 14, thereby causing the magnetically conductive heating layer 14 to generate heat. When the material of layer 14 includes graphite, due to the characteristics of the material of the magnetically conductive heating layer 14, it can emit infrared rays when heated, so that infrared heating can be realized for the pot body 32. At the same time, due t...

Embodiment 2

[0109] like figure 1 and figure 2 As shown, a cooking plate 1 is proposed according to one embodiment of the present invention, comprising a plate body 12, a magnetically permeable heating layer 14 and a protective structure 16 arranged in sequence. Between the structures 16, the contact area with the air can be reduced, and it can work reliably at a higher temperature for a long time.

[0110] Specifically, when the magnetically conductive heating layer 14 senses an alternating magnetic field perpendicular to itself, it will cut the magnetic field to generate eddy currents on the surface of the magnetically conductive heating layer 14, thereby causing the magnetically conductive heating layer 14 to generate heat. When the material of layer 14 includes graphite, due to the characteristics of the material of the magnetically conductive heating layer 14, it can emit infrared rays when heated, so that infrared heating can be realized for the pot body 32. At the same time, due t...

Embodiment 3

[0119] like figure 1 and figure 2 As shown, a cooking plate 1 is proposed according to one embodiment of the present invention, comprising a plate body 12, a magnetically permeable heating layer 14 and a protective structure 16 arranged in sequence. Between the structures 16, the contact area with the air can be reduced, and it can work reliably at a higher temperature for a long time.

[0120]Specifically, when the magnetically conductive heating layer 14 senses an alternating magnetic field perpendicular to itself, it will cut the magnetic field to generate eddy currents on the surface of the magnetically conductive heating layer 14, thereby causing the magnetically conductive heating layer 14 to generate heat. When the material of layer 14 includes graphite, due to the characteristics of the material of the magnetically conductive heating layer 14, it can emit infrared rays when heated, so that infrared heating can be realized for the pot body 32. At the same time, due to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature resistance | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap