Method and device for load control and full-electric high-altitude operation equipment

A high-altitude, all-electric technology, applied in the direction of lifting devices, lifting equipment safety devices, etc., can solve the problem of low environmental adaptability, and achieve the effect of improving adaptability and improving working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

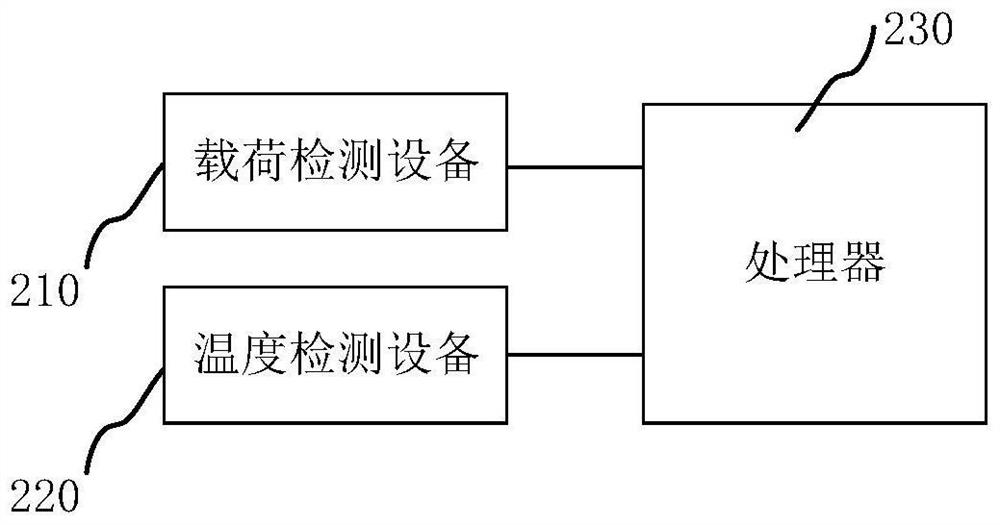

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

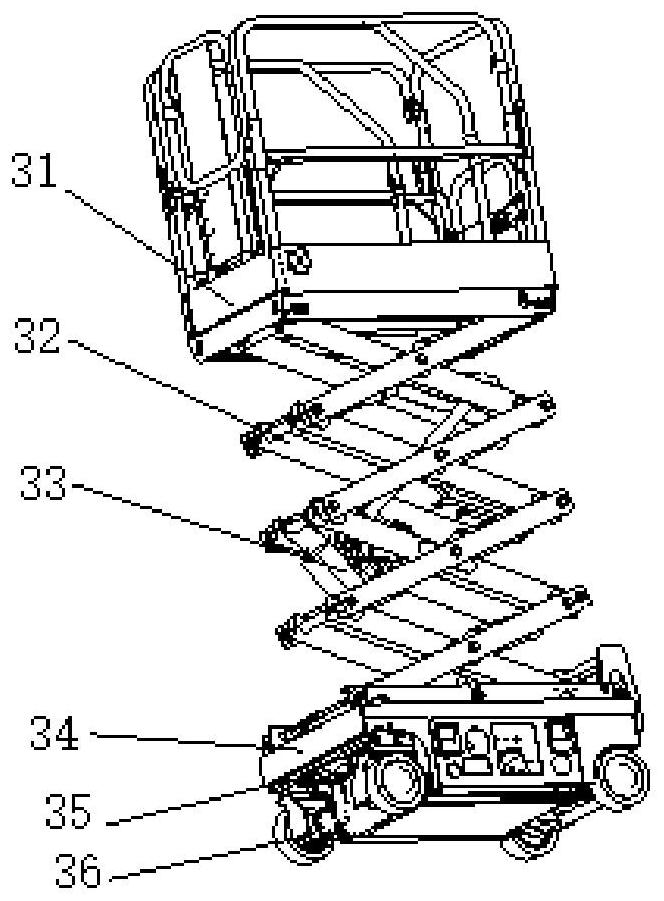

[0039] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0040] In a low temperature environment, the decrease in temperature will easily cause the viscosity of the reducer, the oil in the push rod screw or the grease in the motor bearing to increase or freeze, resulting in an increase in static resistance, which adds an additional load to the push rod drive motor . If the equipment is lifted with a large load, the push rod drive motor may stall due to insufficient starting torque, and even cause the push rod drive motor to burn out. In addition, the brittleness of the material increases at low temperatures, and the output shaft of the push rod drive motor or reducer may There is a possibility of breakage.

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com