Developing box

A developing cartridge and transmission component technology, which is applied in the developing cartridge field, can solve the problems of low yield, complex developing cartridge structure, high processing and manufacturing difficulty of the developing cartridge, etc., and achieves the effects of low processing and manufacturing difficulty, and simple realization method and structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the structure and other aspects of the shadow cartridge of the present invention will be further described in detail through specific implementation methods and with reference to the accompanying drawings.

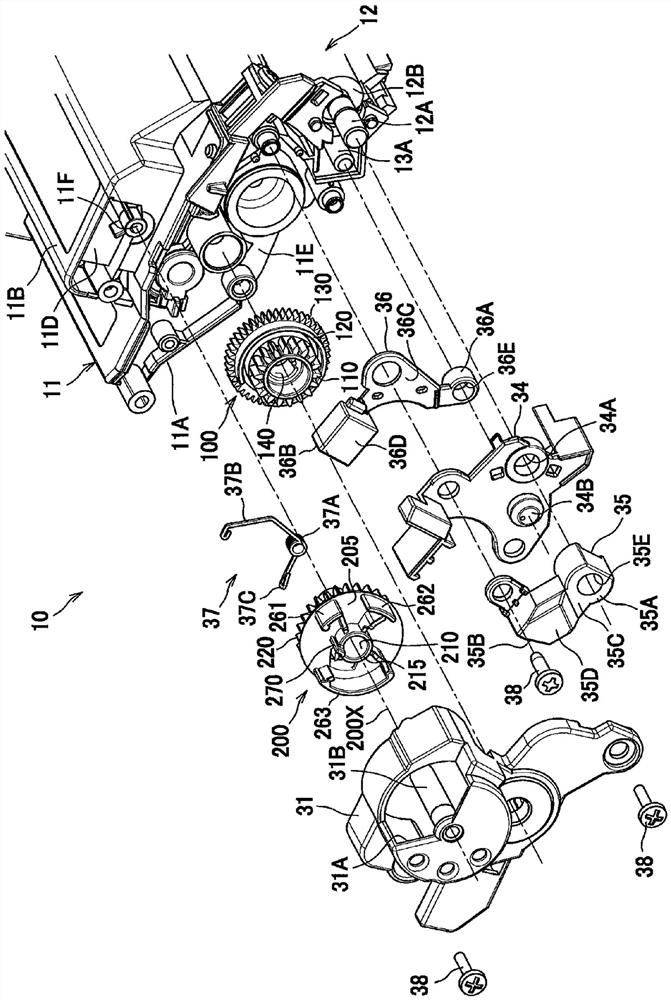

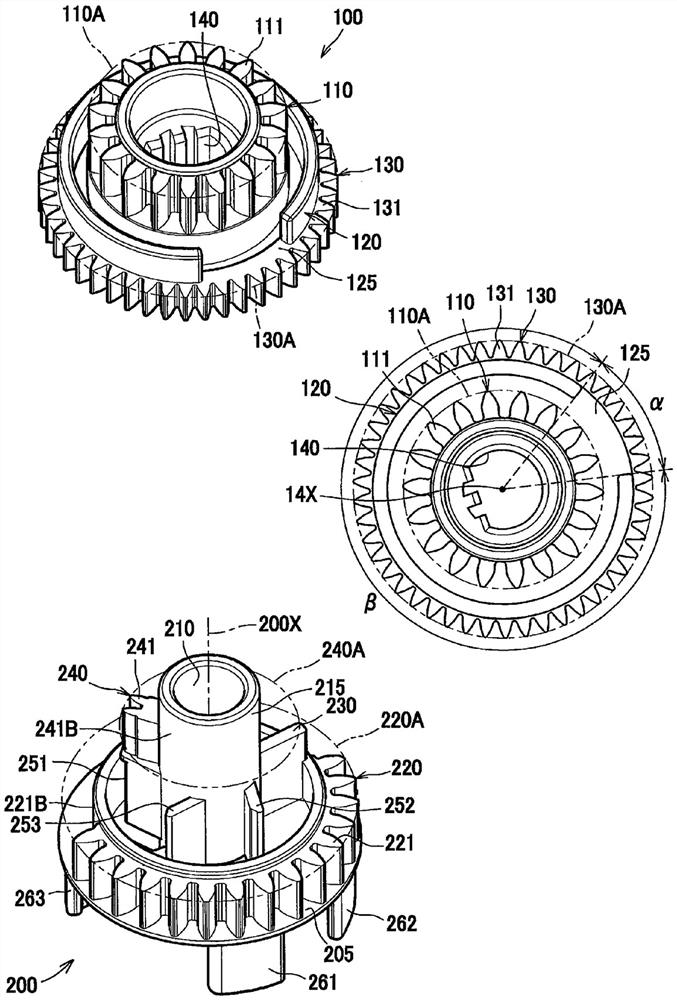

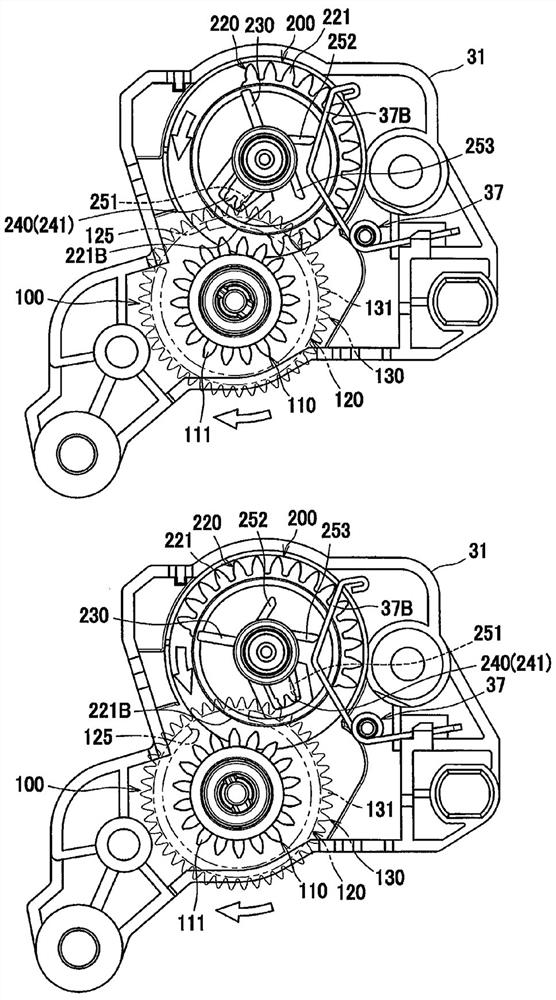

[0036] Figure 4 and Figure 5is a perspective view of the developing cartridge of the present invention according to the first embodiment. The developing cartridge of the present invention includes a housing 1, a transmission assembly 2, a rotatable member (not shown) and an end cover 3, wherein the housing 1 includes sidewalls 11 on both sides and formed inside for accommodating the rotatable member or carbon Powder (developer) cavity. The rotatable member includes, for example, a developing roller, a powder feeding roller, or a stirring frame, and the two ends of the rotatable member are rotatably mounted on the two side walls 11 of the casing 1 . The transmission assembly 2 is installed at one end of the housing 1 and is located between the side ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap