Pig farm equipment life cycle prediction method based on time sequence signals

A time series signal and life cycle technology, applied in forecasting, instrumentation, data processing applications, etc., can solve problems such as the inability to predict the life cycle of pig farm equipment and affect the normal use of pig farm equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

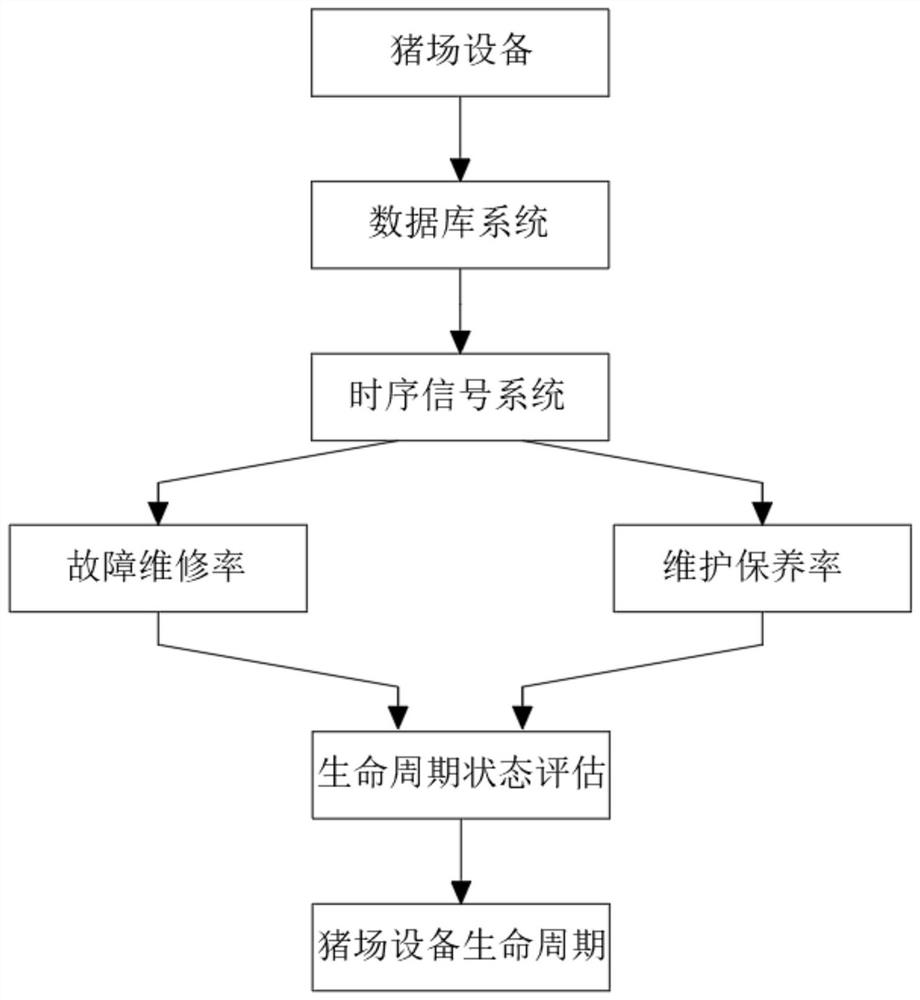

Method used

Image

Examples

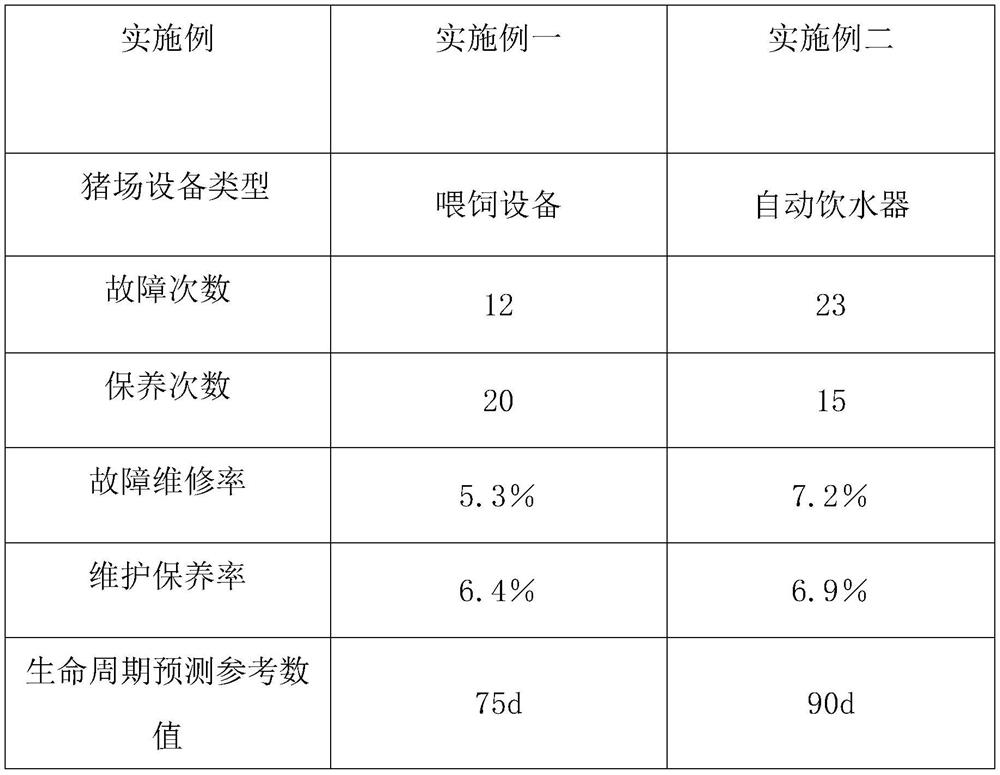

Embodiment 1

[0047] Time-based signaling life cycle prediction method, including the following steps:

[0048] Step 1: Establish a complete database system, incorporate the device information classification into the database system (all data, maintenance data, maintenance data, running data);

[0049] Step 2: In the first time, the pig farm equipment is used to record the number of faults, the number of maintenance, the number of maintenance, the number of maintenance, the number of maintenance, the number of maintenance, the number of maintenance, maintenance The number of times, the number of maintenance, and the failure, maintenance, maintenance, maintenance time of the pig farm equipment;

[0050] Step 3: Incorporate the data information of step II into the database system, the timing signal system in the database system puts a pig farm device for the first time to divide a few small time intervals;

[0051] Step 4: In the time interval divided by the timing signal system, the pig farm equ...

Embodiment 2

[0066] Time-based signaling life cycle prediction method, including the following steps:

[0067] Step 1: Establish a complete database system, incorporate the device information classification into the database system (all data, maintenance data, maintenance data, running data);

[0068] Step 2: In the first time, the pig farm equipment is used to record the number of faults, the number of maintenance, the number of maintenance, the number of maintenance, the number of maintenance, the number of maintenance, the number of maintenance, maintenance The number of times, the number of maintenance, and the failure, maintenance, maintenance, maintenance time of the pig farm equipment;

[0069] Step 3: Incorporate the data information of step II into the database system, the timing signal system in the database system puts a pig farm device for the first time to divide a few small time intervals;

[0070] Step 4: In the time interval divided by the timing signal system, the pig farm equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com