Energy-saving poultry feed drying treatment device

A drying treatment and feed technology, which is applied in the direction of dry cargo handling, drying gas arrangement, feed, etc., can solve the problems of prolonging the drying time of feed, incomplete feed drying, energy waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail with reference to the drawings in the embodiments of the present invention.

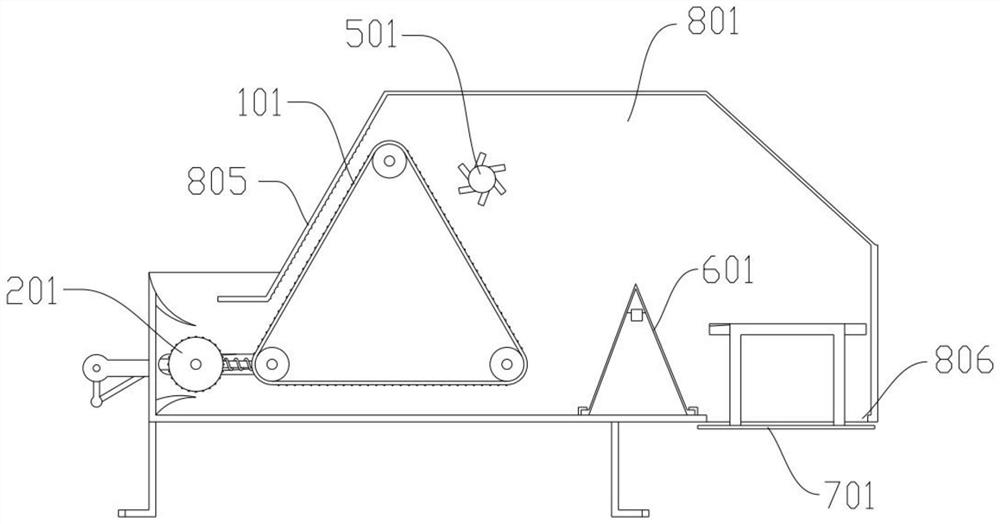

[0017] Referring to 1-10, it shows a schematic diagram according to an embodiment of the present invention to facilitate circulation of dry feed, further,

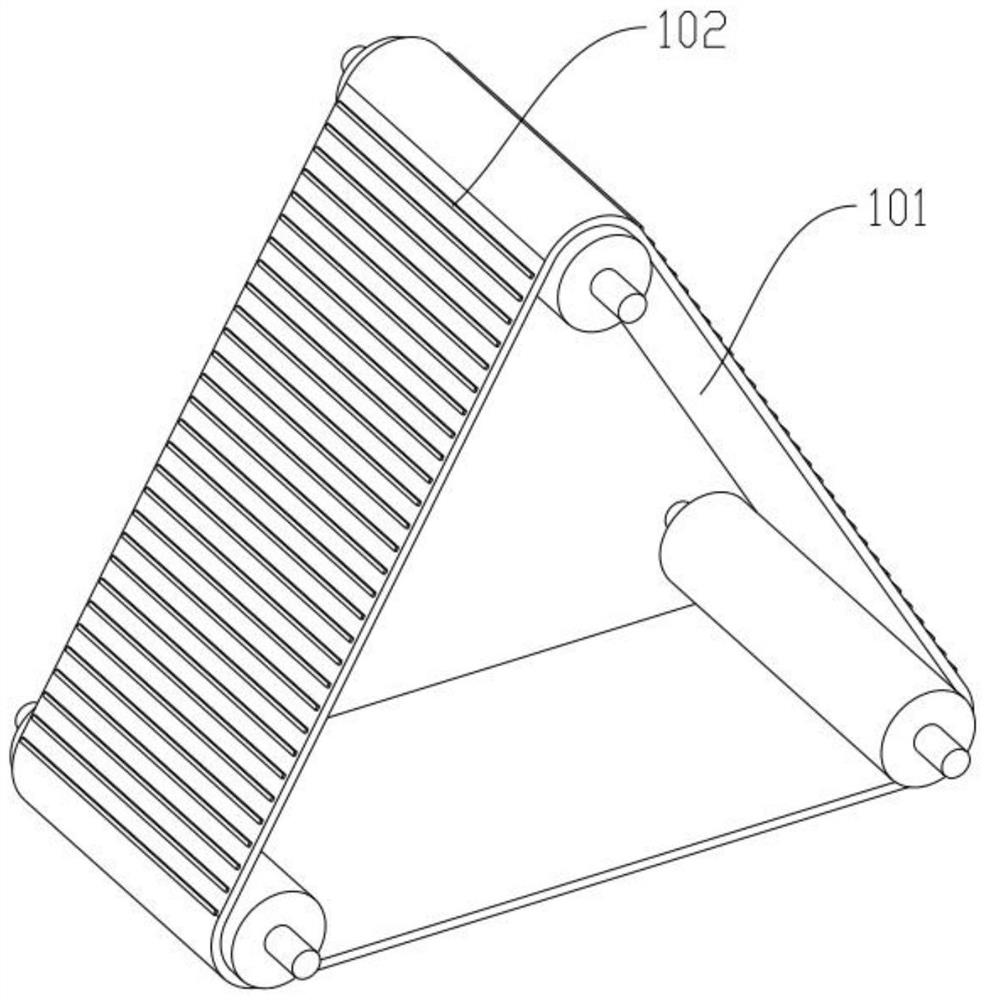

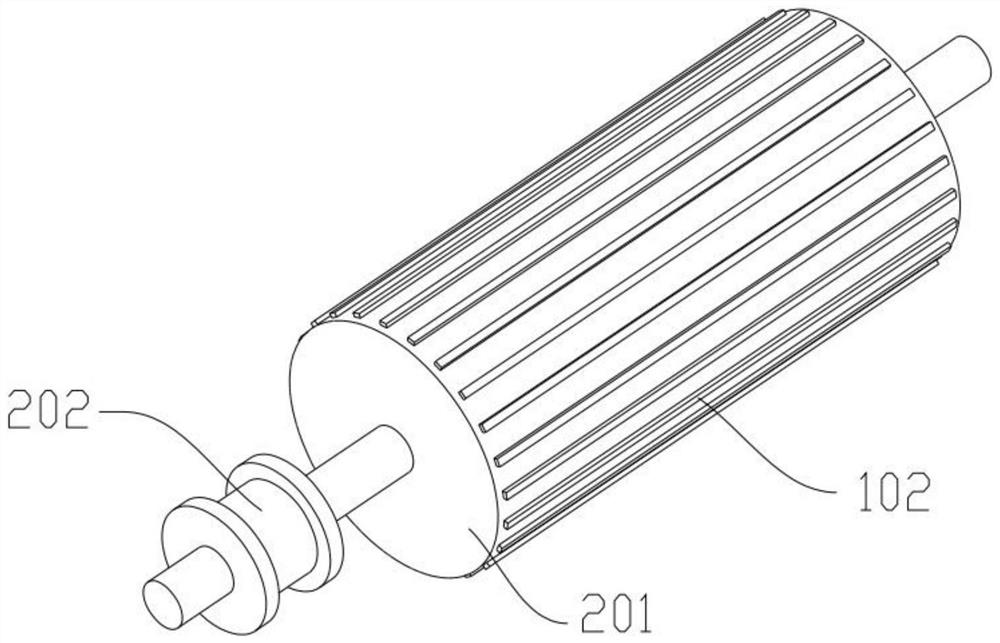

[0018] The drying box 801 is provided with a material inlet 804 and a material outlet 806, a V-belt 101 and an air cylinder 501 are rotatably connected in the drying box 801, a swash plate 805 is arranged in the drying box 801, and a transmission roller 201 is rotatably connected to the driving mechanism. The driving mechanism can drive the transfer roller 201 to move laterally on the drying box 801, the sorting cloth 601 is detachably connected in the drying box 801, the sieve plate 701 is slidably connected below the discharge port 806, and the V-belt 101 is externally connected with a motor.

[0019] When people dry the feed, they usually need to dry a large amount of feed, but the traditiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com