High-frequency blade passing frequency extraction method based on vibration signals of outer casing of gas turbine

A technology of vibration signal and outer casing, which is used in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problem of time-frequency aggregation, improve high-frequency blades, and cannot accurately separate and extract vibration signals of gas turbines. problems such as low frequency resolution, to achieve the effect of fault monitoring and early warning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

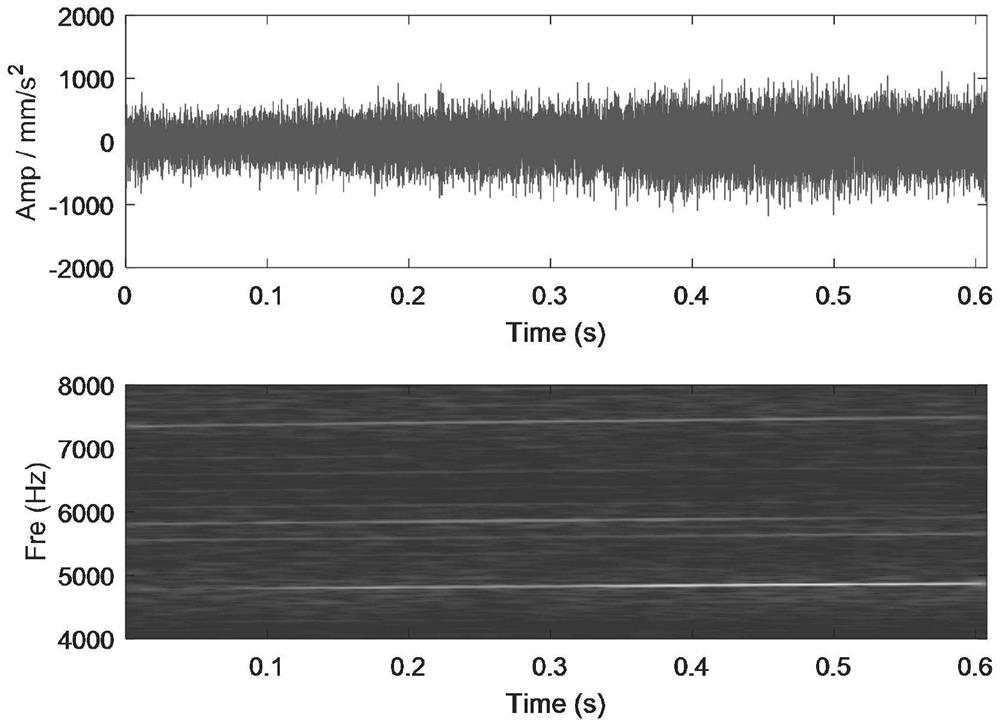

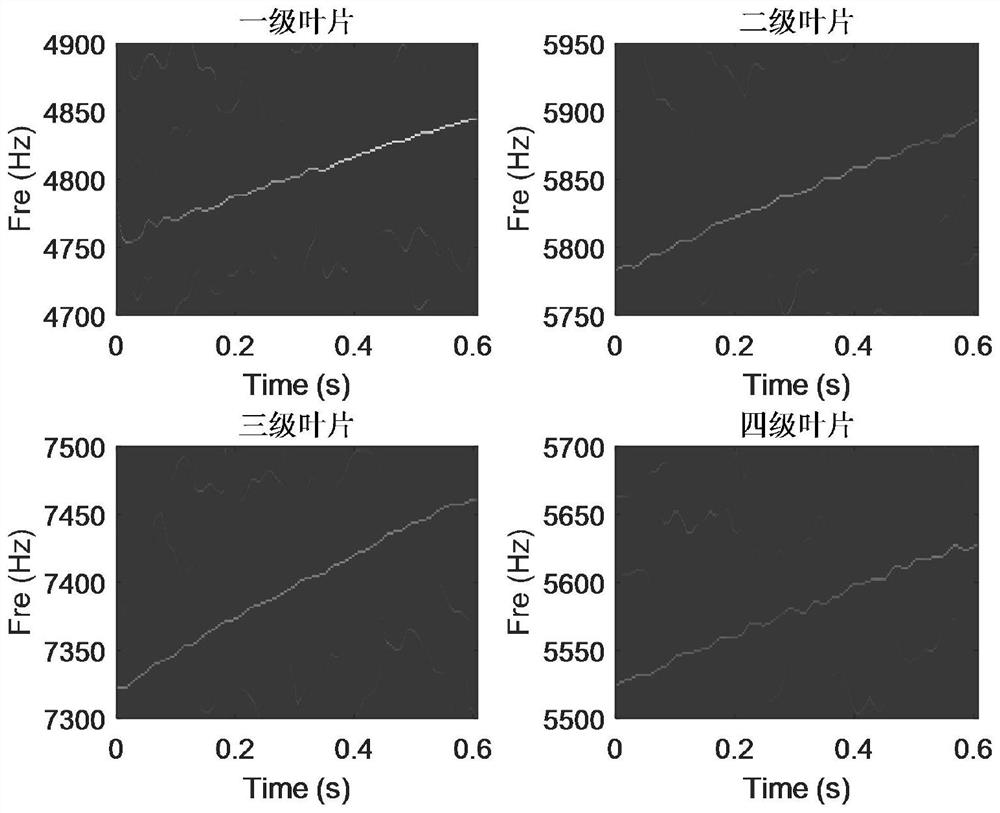

[0042] The data in this embodiment are obtained in the field test of a certain gas turbine, which is a double-rotor gas turbine. The BK4519 acceleration sensor is used to measure the vibration acceleration signal of the outer casing of the gas turbine. The sensor is fixed on the designed bracket, and the bracket is fixed on the outer casing by bolts. During the test, the high and low pressure rotors were running at variable speeds. The speed of the high and low pressure rotors was in a state of increasing speed in the range of 100-200rpm, and the sampling frequency was 51200Hz.

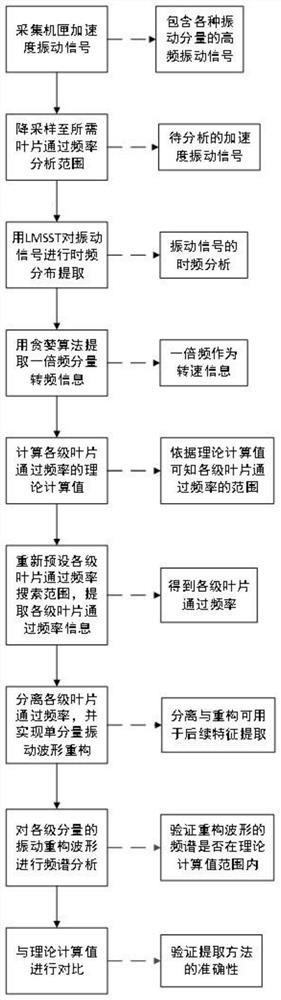

[0043] A high-frequency blade passing frequency extraction method based on the vibration signal of the outer casing of the gas turbine, the process is as follows figure 1 As shown, the specific steps are as follows:

[0044] S1. Use the vibration acceleration sensor to collect the vibration acceleration signal of the outer casing to be analyzed, install the vibration acceleration sensor on the bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com