Urban rail transit automatic inspection equipment

A technology for urban rail transit and automatic inspection, applied in track cleaning, railway auxiliary equipment, equipment fixed on vehicles, etc., can solve the problems of low-efficiency high-speed railway, single detection function, and inconvenient detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

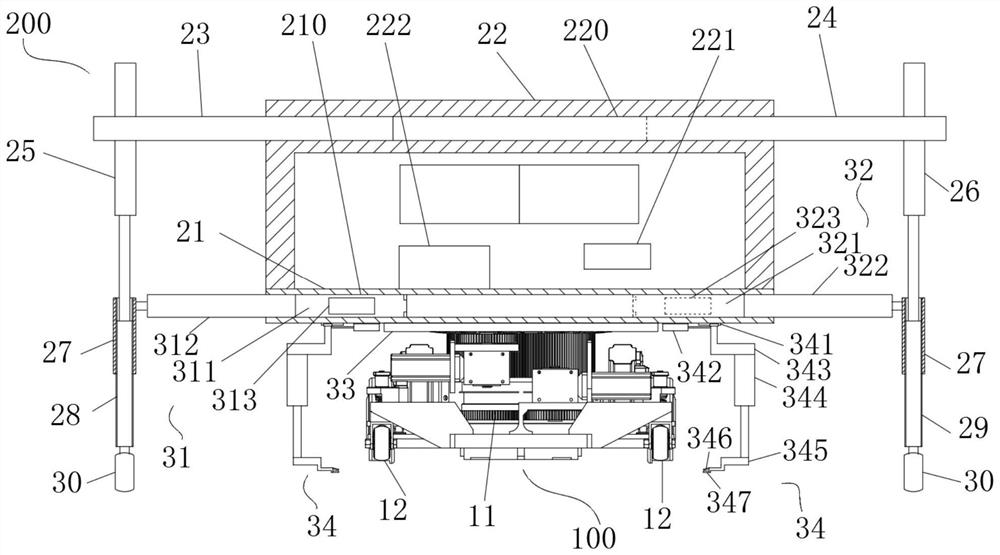

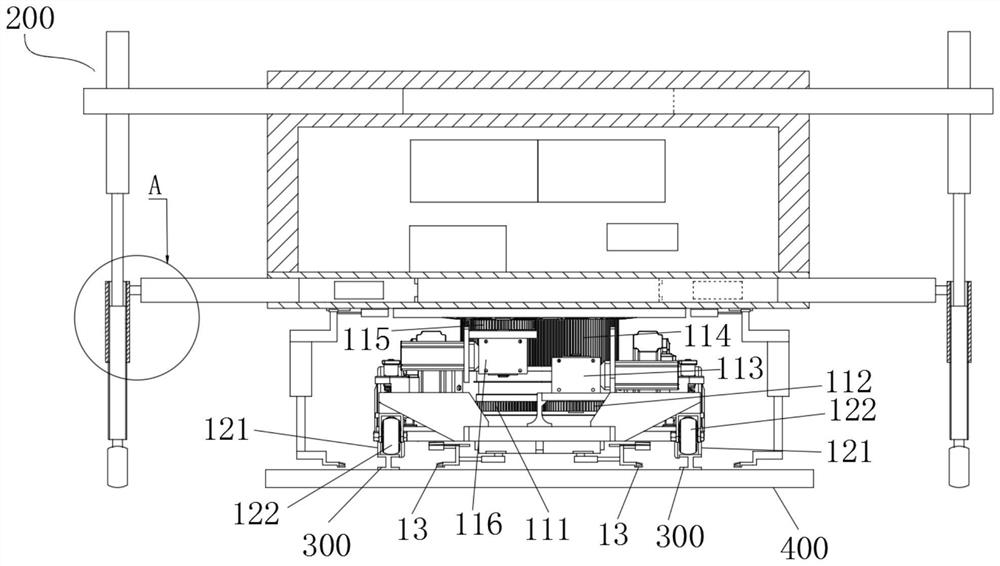

[0036] like Figure 1-Figure 13 As shown, a kind of urban rail transit automatic inspection equipment described in this embodiment includes an automatic walking inspection device 100 and a driving mechanism 200 that controls the automatic walking inspection mechanism to enter or leave the track correspondingly; the automatic walking inspection The device 100 includes an automatic traveling device 12 and a lifting device 11 arranged on the automatic traveling device 12 .

[0037] The driving mechanism 200 includes a platform 21 and a control room 22 fixed on the platform 21. Two first automatic telescopic rods 31 and two second automatic telescopic rods 32 are respectively arranged on the left and right sides of the platform 21. The top left and right sides of the control room 22 Two first sliding rods 23 and two second sliding rods 24 are slidingly connected on both sides respectively, and the ends of the two first automatic telescopic rods 31 and the two second automatic tele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com