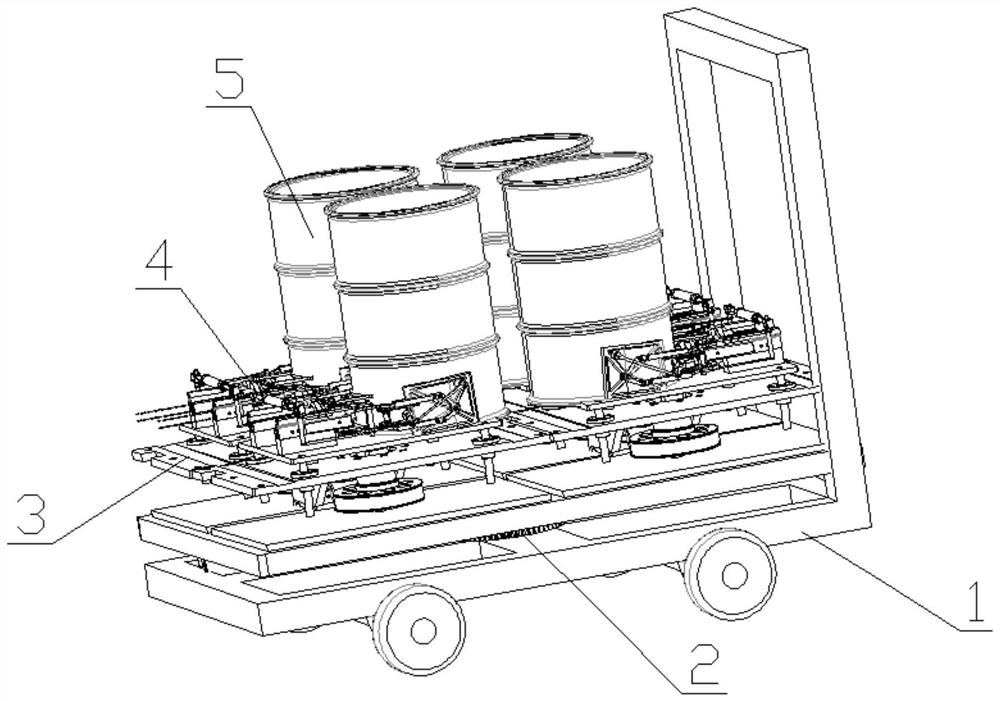

Charging basket transfer equipment and transfer method

A technology of material barrels and equipment, which is applied in the field of material barrel transfer equipment and transfer, can solve the problems of affecting the transportation efficiency, time-consuming and labor-intensive flatbed vehicles, etc., and achieve the effect of high transmission efficiency, sensitive action, and buffer vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

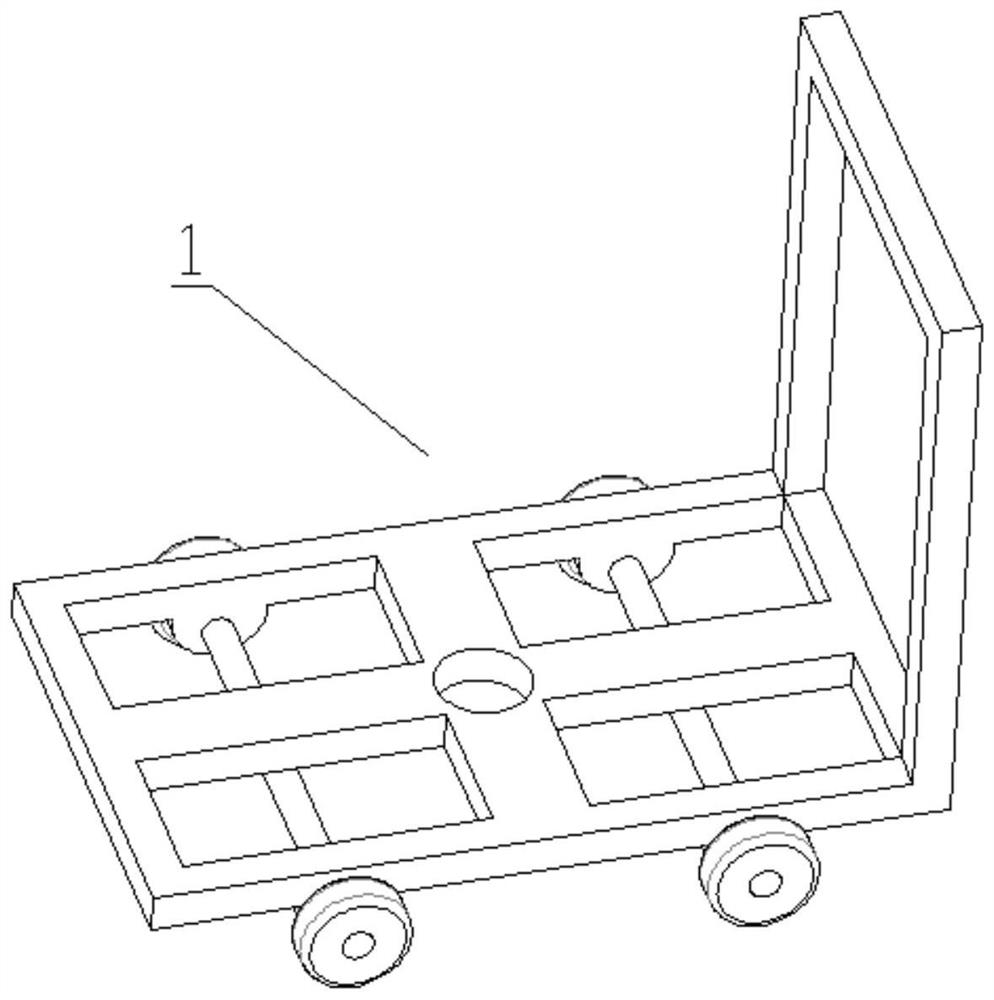

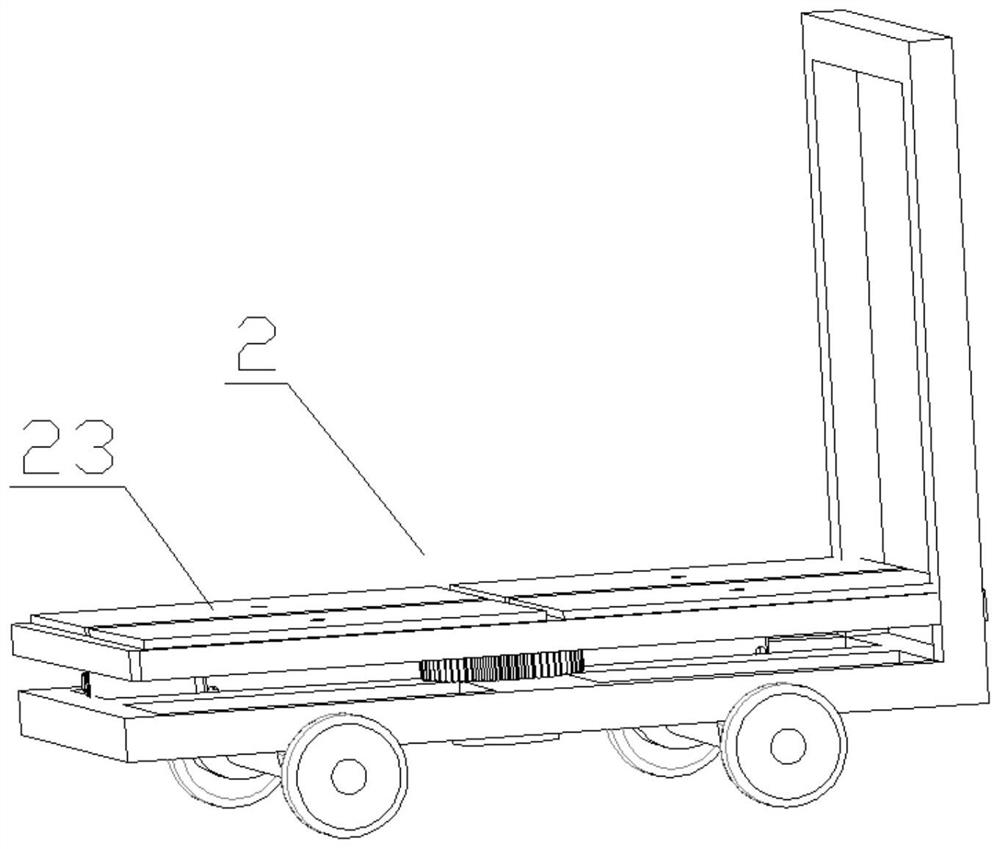

[0047] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0048] Usually, the material barrels are placed on the flatbed truck for transport. The usual practice is to place the larger diameter buckets on the bottom of the flatbed truck first, and then place the smaller diameter buckets on the larger diameter. above the bucket. Although this kind of operation can ensure the stability of the material barrels during transportation to a certain extent, when there are many material barrels, it is necessary to manually rotate the flatbed transport truck. It is time-consuming and labor-intensive to turn the flatbed transporter.

[0049] On the flatbed transport vehicle, first place the barrel with a relatively large diameter and then place the barrel with a relatively small diameter. It is necessary to select the barrel with a relatively large diameter first among many barrels, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com