Airbag and airbag module, and method for producing one-piece woven airbag and method for producing airbag module

A technology for airbags and side airbags, which is applied in the field of airbags and airbag modules, as well as for the manufacture of one-piece braided airbags and for the manufacture of airbag modules, which can solve the problems of complex assembly of airbag modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

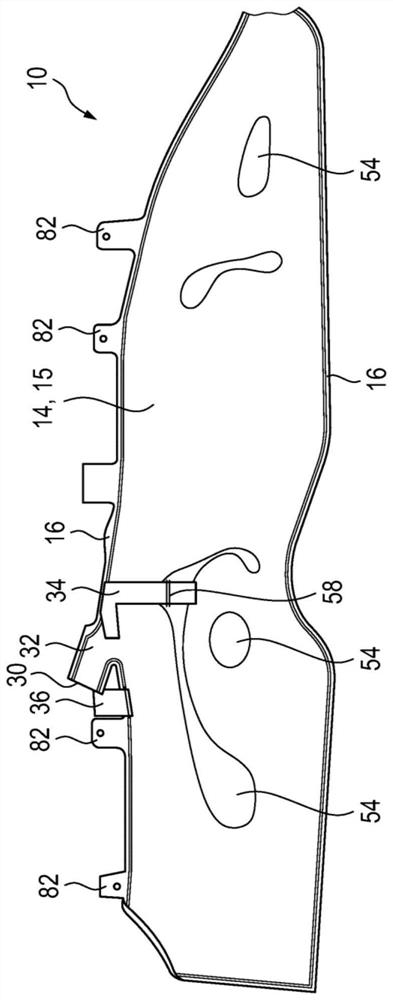

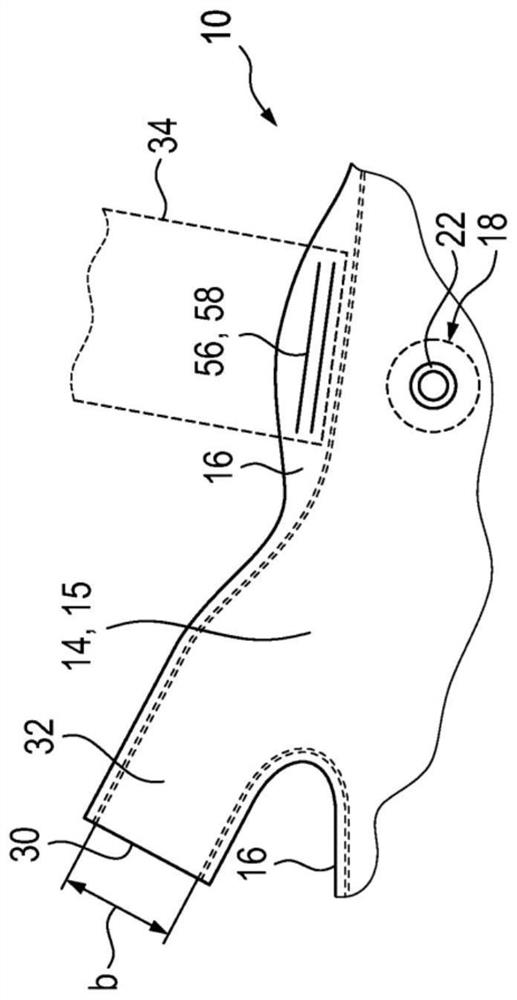

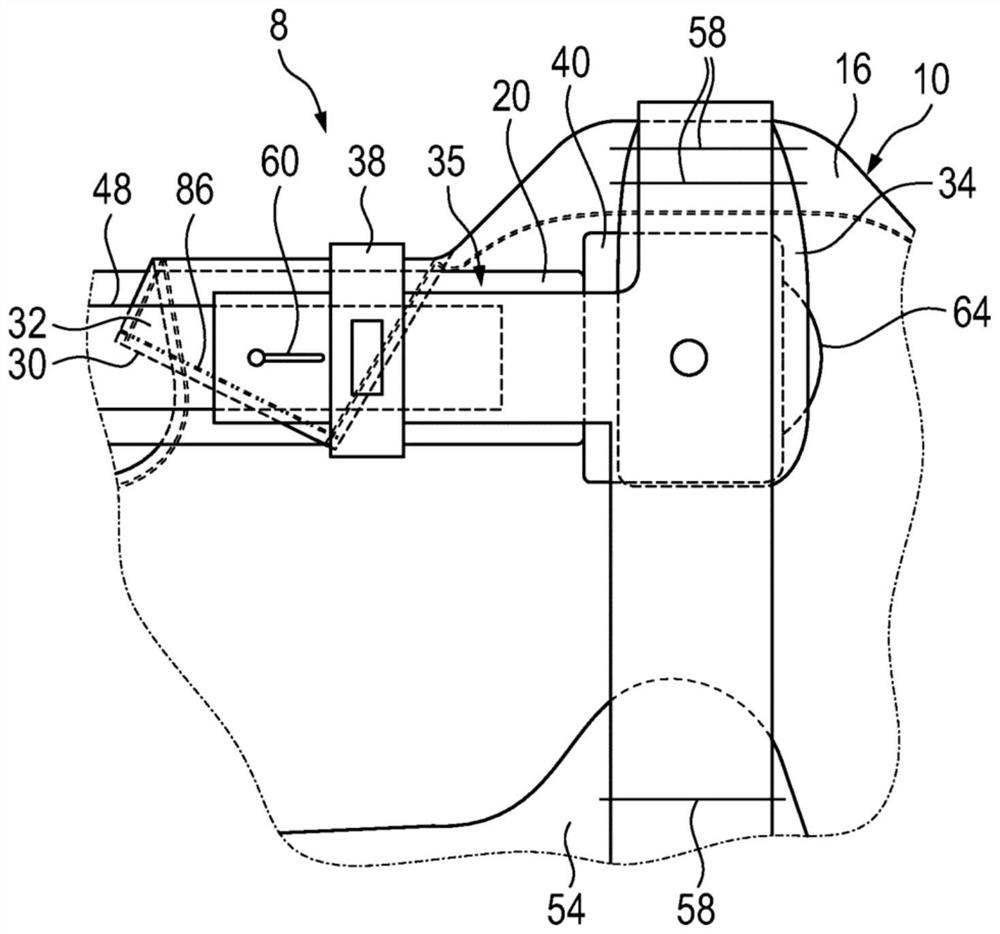

[0053] Figure 1a with 1b An airbag 10 according to the invention is shown, which in the embodiment shown is designed as a head-side airbag 10 .

[0054] The airbag 10 comprises at least two opposing fabric layers 12 and 14 forming at least one inner wall 13 and one outer wall 15 of the airbag 10 . The airbag 10 is produced in one piece by a multilayer weaving process, wherein the fabric layers 12 and 14 are interwoven with one another at least in the edge region 16 . Figure 1b The double dashed lines in , here, indicate the boundary of the edge region 16 from which the textile plies 12 and 14 are not interwoven with each other to form the airbag interior 50 .

[0055] Figure 1a The airbag 10 shown also includes subdivided sections 54 in which the two textile plies 12 and 14 are also interwoven with one another, so that the airbag 10 is not inflated in this region.

[0056] The airbag 10 shown also includes a plurality of airbag fastening sections 82 which are provided for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com