Prying-resistant door

A technology of tamper-resistant doors and tamper-resistant steel, applied in the field of tamper-resistant doors, can solve the problems of easy jamming, threats to personal and property safety, and high manufacturing and installation costs, so as to prevent violent demolition, increase commercial value, and increase effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

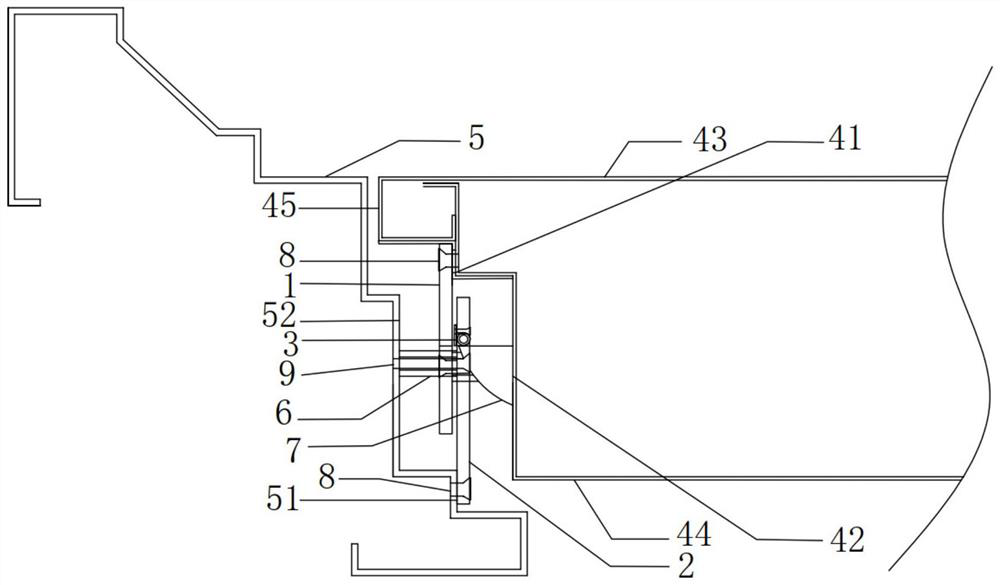

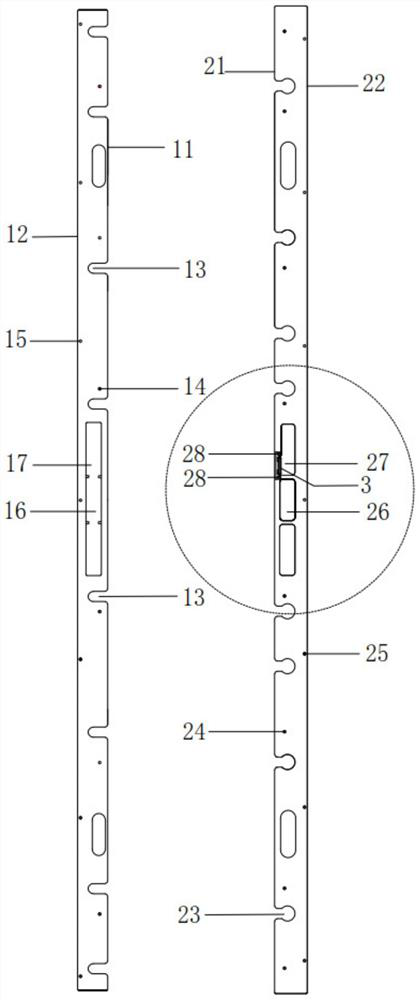

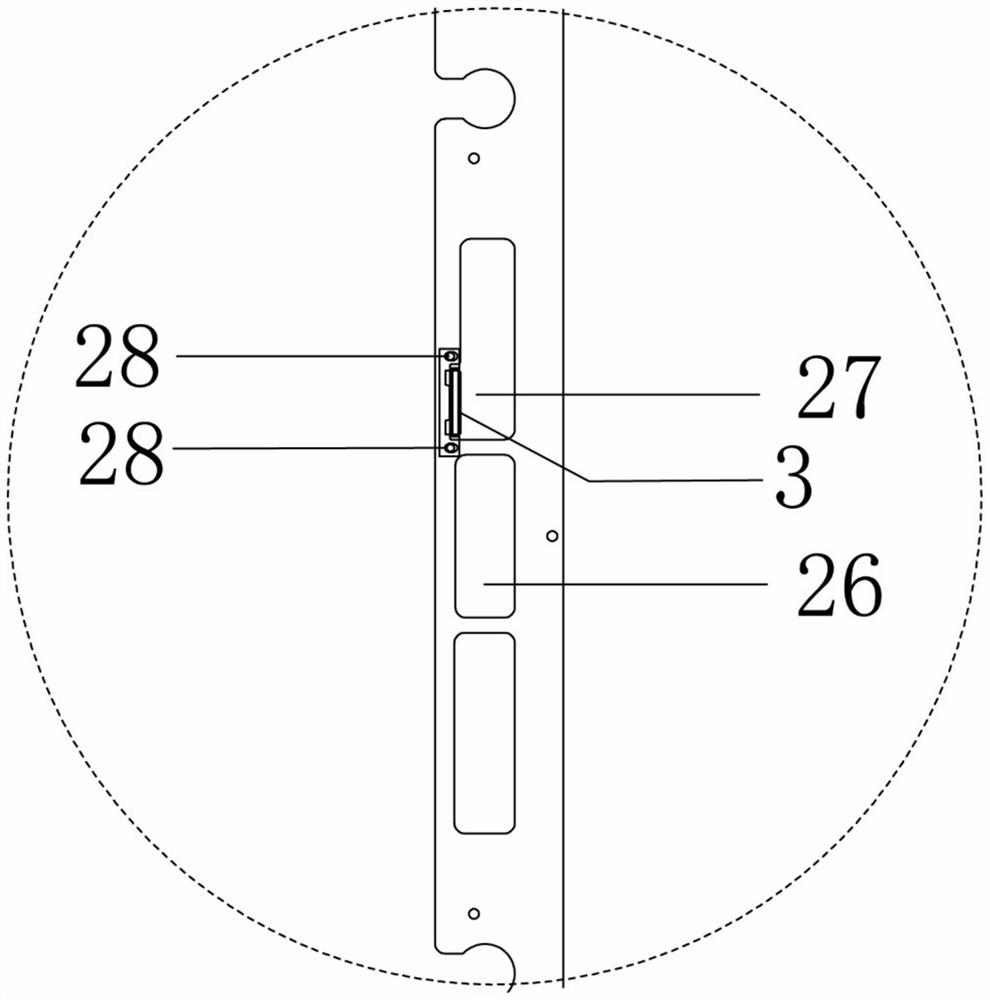

[0036] as Figure 1As shown, referring to the accompanying drawings: 1-3 and 6-7: Example 1 provides a single door anti-pry door open outwards, comprising a door frame, a door leaf and a lock, the door leaf close to the lock side is a lock side door leaf 4, the lock side door leaf 4 is equipped with a lock tongue and a diagonal tongue 7, the door leaf is rotated and connected to the door frame by a hinge, the door leaf connected to the hinge is a hinged side door leaf, the door frame connected to the hinge is a hinged side door frame, the outer façade of the lock side door leaf 43 extends and bends to form a protective cover plate 45, and the protective cover plate 45 is provided with a sealing strip The inner façade of the lock side door leaf 44 is folded to form a lock side door leaf side facade 42 having steps. The first anti-skid steel 1 is provided with a fan side bushing 13 with the fixing bolt 82 of the second anti-pry steel 2, the first anti-skid steel without a casing givi...

Embodiment 2

[0042] as Figure 1 As shown, with reference to the accompanying drawings: 4-7: The present embodiment is an anti-pry door of a seed mother door, which is different from Example 1 is that the second anti-pry steel is fixed to the side façade of the sub-door leaf near the mother door leaf, different from the single door leaf anti-pry door, the second anti-pry steel is provided with a sub-door leaf of the heaven and earth pole opening and closing adjustment device compatible with the adjustment hole 29, through the hole can be pulled the heaven and earth rod adjustment device, so that the sub-door leaf locked on the door frame or the sub-door leaf free opening and closing. The second anti-pry steel and the sub-door leaf side façade fixed in the first anti-pry steel and wooden door leaf fixation is similar, when the anti-pry door is in a locked state, the second anti-pry steel is located between the first anti-pry steel and the side façade of the lock side door leaf.

Embodiment 3

[0044] The present embodiment is based on Examples 1 and 2, the use of adjustable hinges, through the hinge on the adjustment bolt, can make the door leaf displacement, thereby correcting the position of the door.

[0045] as Figure 8Shown, the hinge comprises a door leaf sheet 91, a door frame sheet 92, a hinged hinge 96 and a square slot 93 of the accommodating door frame sheet 92, a square slot 93 riveted or welded to the hinged side door frame; the square slot 93 is provided with at least 4 adjustment bolts, wherein the bolt cap 94 under the 2 sheets near the hinge hinge shaft is located under the page plate, the bolt bolt may be rotated through the round hole above the bolt, the rotation of the bolt 94 under the page plate will correspondingly make the door frame page plate 92 away from or close to the square groove. The nut is located on the top of the door frame page plate on the plate bolt 95 and the bottom of the page bolt 94 and is the door leaf to occur a large position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com