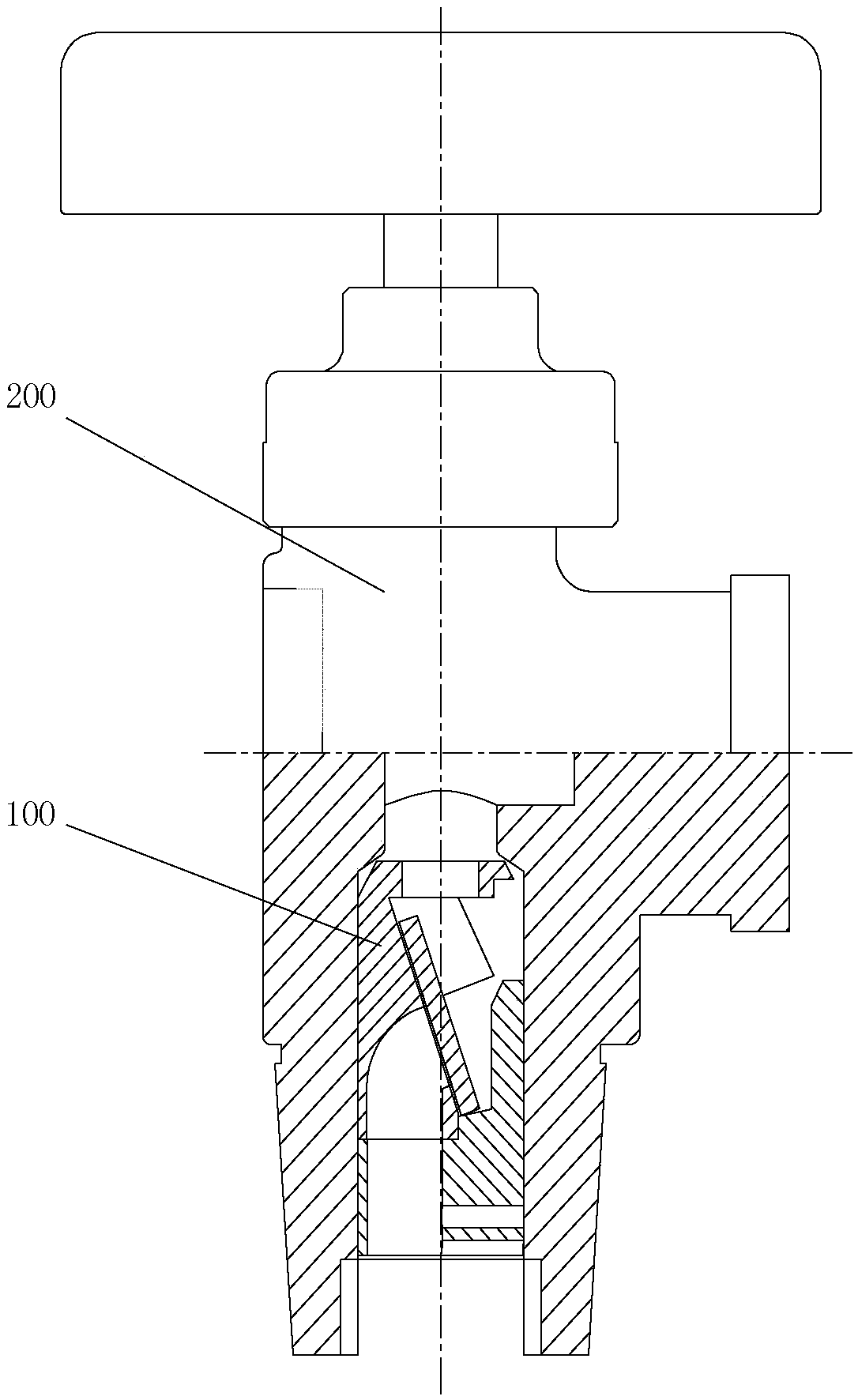

An anti-filling spool and valve

An anti-filling and valve core technology, applied in the field of valve cores, can solve the problems of low reliability of anti-filling, easy to break the static equilibrium state of the opening limit, etc., so as to improve the safety of anti-filling, improve the opening difficulty, The effect of improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

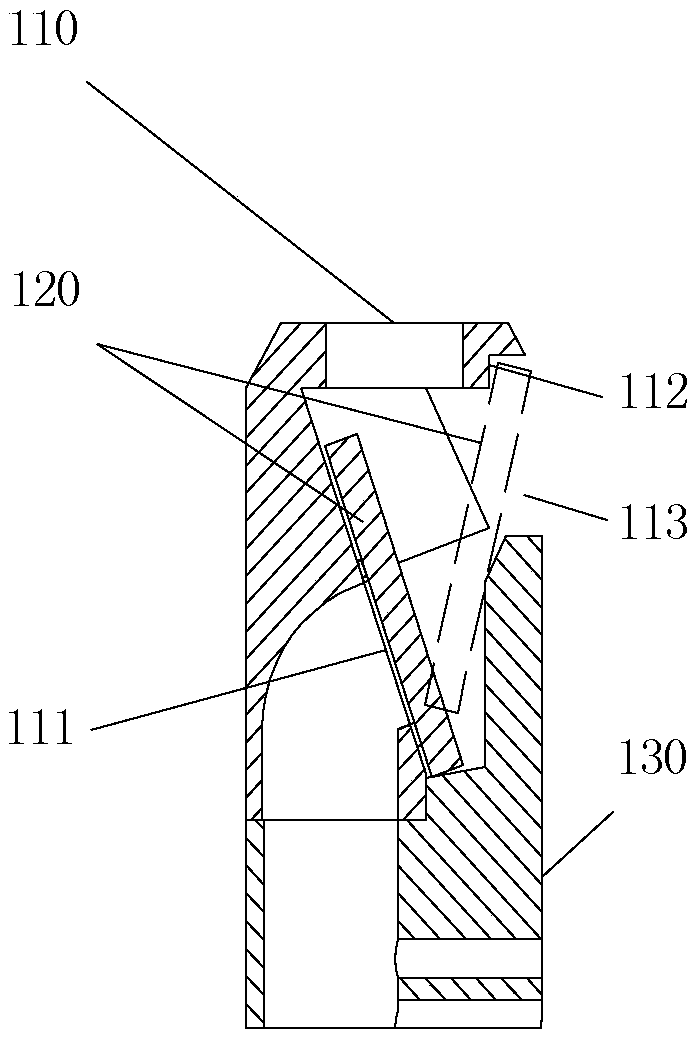

[0052] Such as Figure 7 to Figure 11 As shown, the anti-filling valve core 300 of the present invention includes an upper valve core 310, a lower valve core 330, a sail plate 320, a through filling gas through hole arranged on the upper valve core and the lower valve core, and a The sail chamber 340 between the spool 310 and the lower spool 330 .

[0053] The lower spool 330 includes an outer surface (such as Figure 14 As shown), it has been ensured that the filling gas is filled into the steel cylinder through the filling gas hole of the valve core.

[0054] The sail chamber 340 includes a spool slope 317 arranged along the slant direction of the spool axis N, a spool top 316 located on the top of the upper valve body 310, and the outer surface of the spool top 316 is tightly fitted with the spool cavity wall ( like Figure 14 As shown), it has b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com