Black tea fermentation method and fermentation device

A technology of a fermentation device and a fermentation method, which is applied in the field of black tea fermentation methods and fermentation devices, can solve problems such as black tea soup, uneven moisture in tea leaves, and difficulty in controlling the degree of fermentation, so as to reduce theabrownin content and increase theaflavin content. Content, the effect of avoiding partial over-fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] Example 1

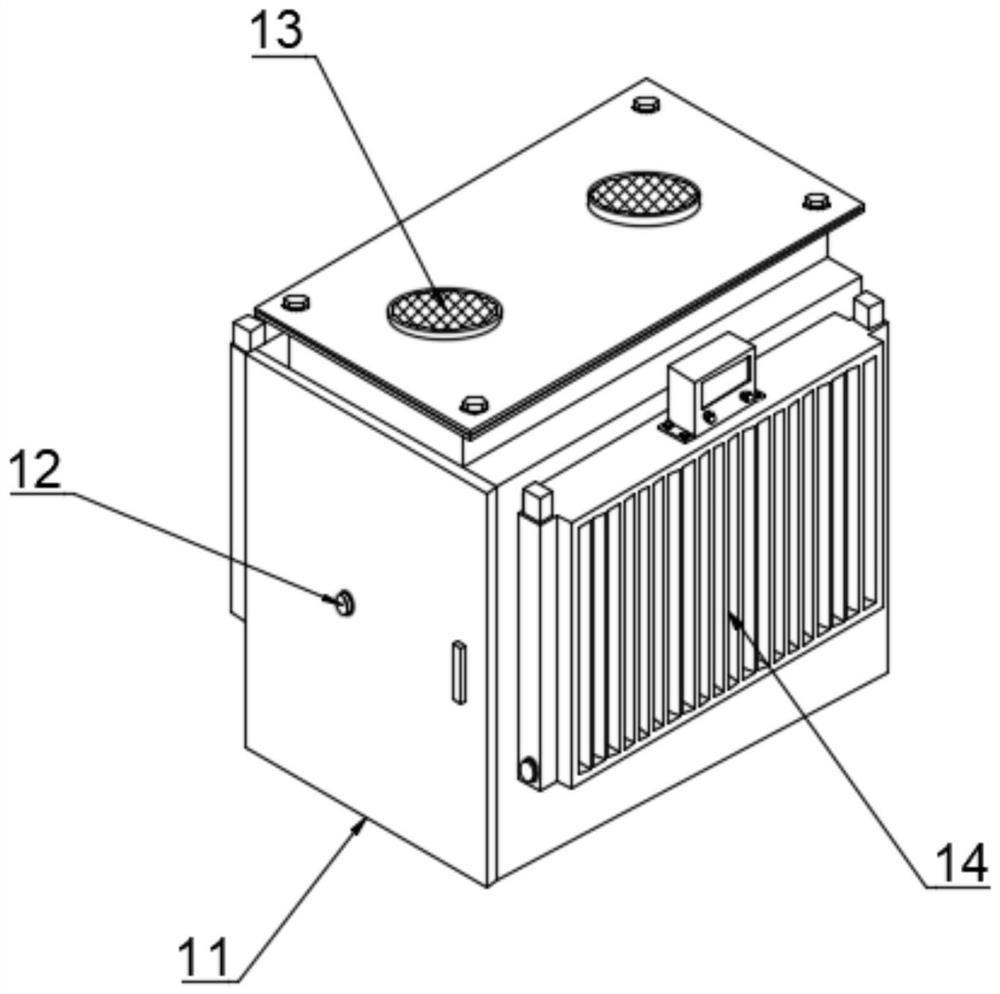

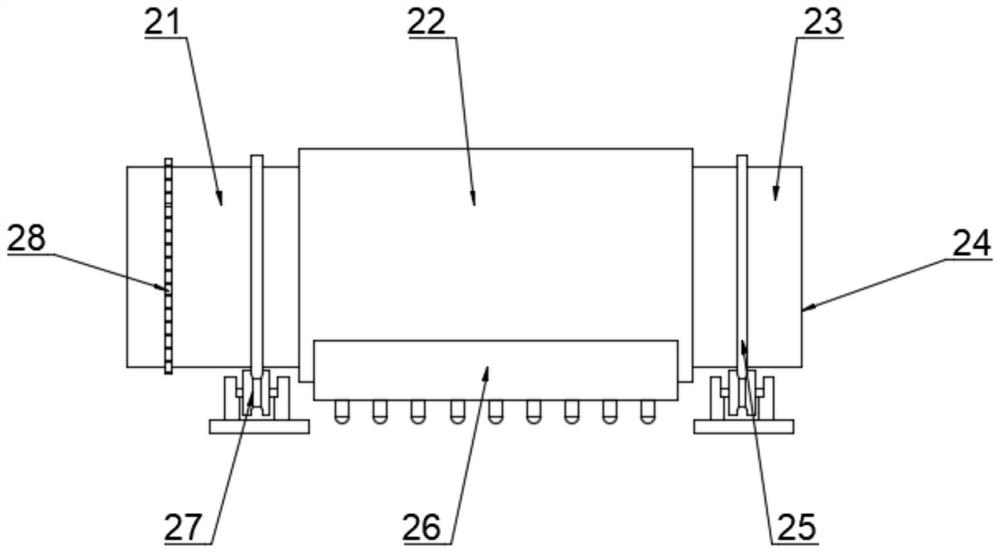

[0034] This embodiment provides a black tea fermentation device, please refer to Figure 1-Figure 4 As shown, it includes a fermentation tank 11 and a fermentation tank 24 arranged inside the fermentation tank 11. Both sides of the bottom wall of the fermentation tank 11 are provided with rollers 27, and the outer walls on both sides of the fermentation tank 24 are provided with guide ribs 25. Ribs 25 are fitted and engaged with idler rollers 27. Fermentation tank 24 can rotate around its central axis inside fermentation bin 11 through guide ribs 25 and idler rollers 27. A ring of racks 28 is fixed on the outer wall of fermentation tank 24. A motor is arranged in the bin 11, and a gear meshing with the rack 28 is fixed on the output end of the motor, so that the fermentation tank 24 can be driven to rotate by the motor;

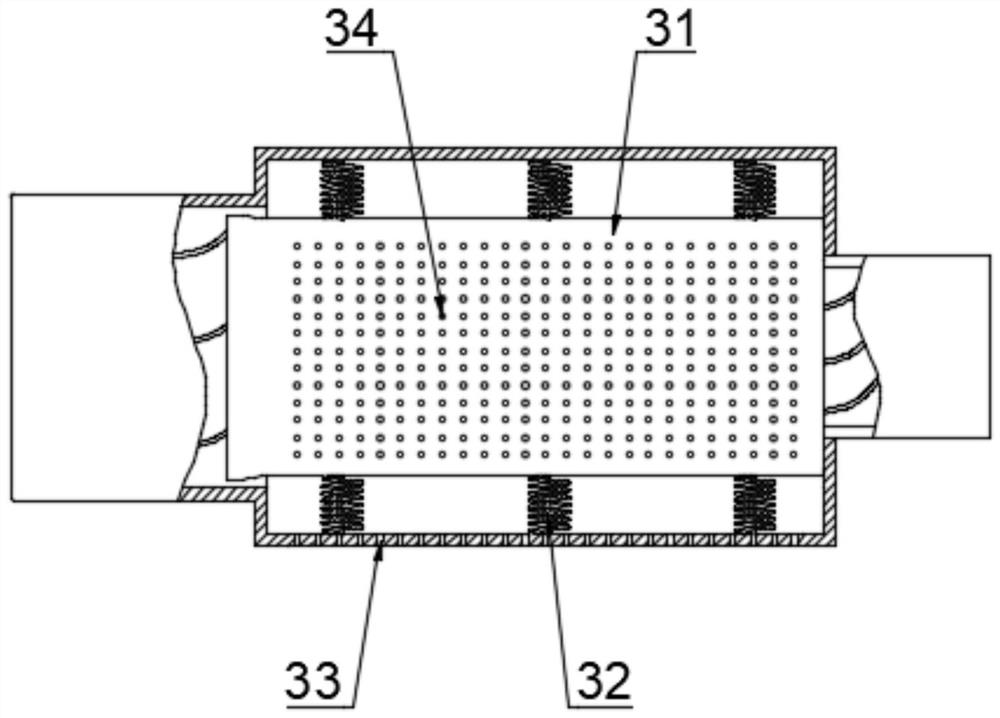

[0035] The fermentation tank 24 is formed by the feeding pipe body 23 , the fermentation pipe body 22 and the discharging pipe body 21 wh...

Example Embodiment

[0043] Example 2

[0044] This example adopts the fermentation device provided in Example 1 to prepare fermented black tea, please refer to Figure 1-Figure 4 The specific implementation process is as follows:

[0045] Step S1: Rotate the steam vent 33 of the fermentation tube body 22 to face the steam separation bracket 26, use high-pressure high-temperature steam to sterilize the inner wall of the entire fermentation tank 24, part of the condensed water is discharged from the steam separation bracket 26, and then Dry the inner wall of the fermentation tank 24 with dry hot air to prevent residual moisture in the inner wall of the fermentation tank 24 from causing the tea leaves to adhere to the inner wall during feeding, and to prevent uneven fermentation caused by uneven internal moisture. The tea leaves are put into the feeding pipe body 23, and the fermenter 24 is driven to rotate to introduce the tea leaves into the inner mesh pipe 31;

[0046] Step S2: take the glucose...

Example Embodiment

[0049] Example 3

[0050] The present embodiment prepares fermented black tea, and the specific implementation process is the same as in Example 2, and the fermentation process parameters are adjusted, and the specific adjustments are as follows:

[0051] In step S2, the concentration of the aqueous glucose solution is replaced with a mass fraction of 10%, and the pH value is adjusted to 4.8 with acetic acid;

[0052] In step S3, the air humidity in the middle of the inner network pipe 31 is maintained at 100%, the temperature is maintained at 35°C, and the fermentation time is controlled as 100min;

[0053] In step S4, the air humidity in the middle of the inner network pipe 31 is maintained at 60%, the temperature is maintained at 15°C, and the fermentation time is controlled at 150 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com