Fabric stretching mechanism, fabric stretching device, fabric setting machine and application of fabric stretching mechanism, fabric stretching device and fabric setting machine

A fabric and shaping roller technology, applied in the direction of fabric surface trimming, shaping/stretching endless fabrics, textiles and papermaking, etc., to achieve the effect of exquisite structural design and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

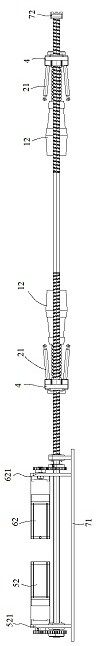

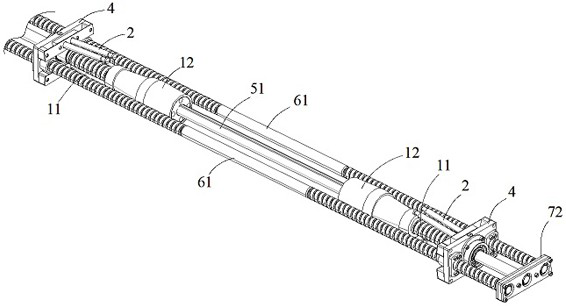

[0057] In addition, in order to improve the stability of the main axis 51 and two stretching screws 61 and avoid axial bias, at one end of the main axis 51 and stretching screw 61 away from the end of the installation seat board 71, there is a stand -like supportBoard 72, the support board 72 has three bearing on the end of the main axis 51 and two stretch screw 61 respectively.

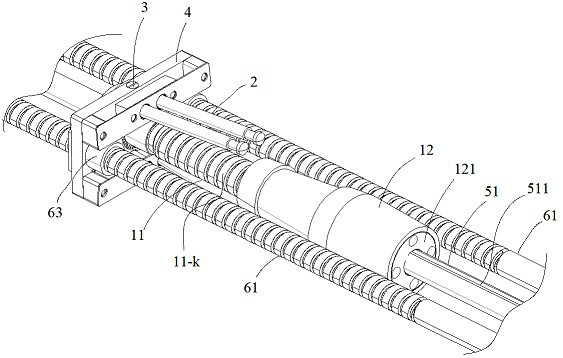

[0058] Reference Figure 4 As well as Figure 5 As well as Figure 7 , The frame 4 has a hole 4-i through the skeleton sleeve 11, and the diameter of the cavity 4-i is slightly larger than the diameter of the skeleton sleeve 11.The end surface of the cylinder 12 and the bearing cover 41 at the opening of the hole 4-i, and fix the sleeve bearing 42 on the skeleton sleeve 11 in the bearing cover 41, so that the skeleton sleeve 11 activity is connected to the shelf on the shelf.On the board 4, and it can rotate around its axis.

[0059] Reference Figure 4 As well as Figure 5 As well as Figure 6 As well as Figu...

Embodiment example 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com