Belt material flow tracking method and device and computer equipment

A belt and material flow technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as poor stability, energy waste, and little accurate tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the purpose, technical solutions and advantages of the present application more clearly understood, the present application will be described in further detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present application, but not to limit the present application.

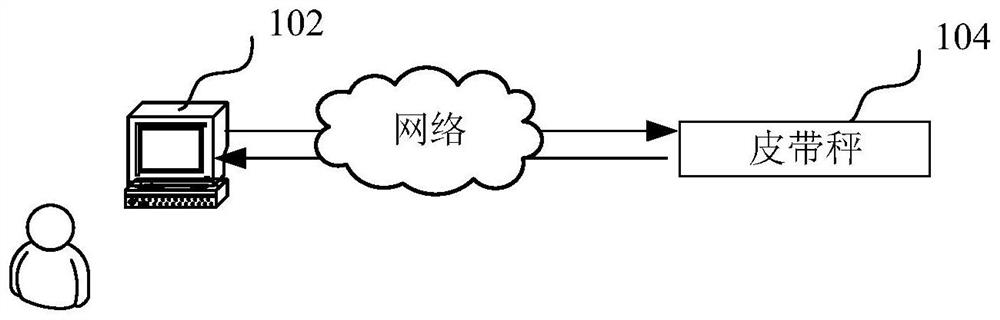

[0054] The belt material flow tracking method provided in this application can be applied to such as figure 1 in the application environment shown. The terminal 102 communicates with the belt scale 104 through the network. The terminal 102 can be, but is not limited to, various controllers, industrial computers, embedded control panels, and PLC devices, and the belt scale 104 is used to measure the instantaneous flow of the belt.

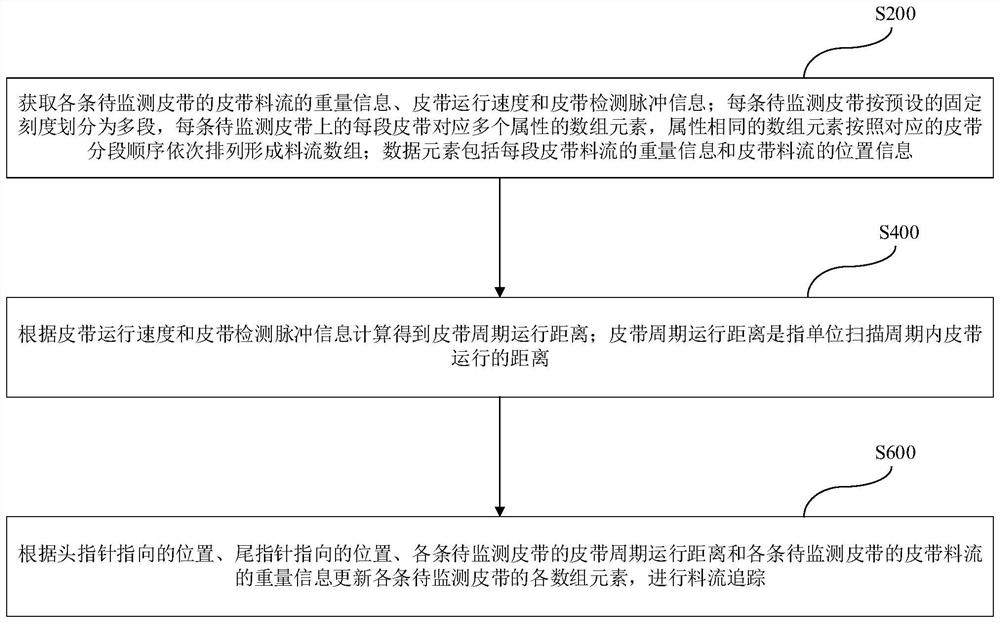

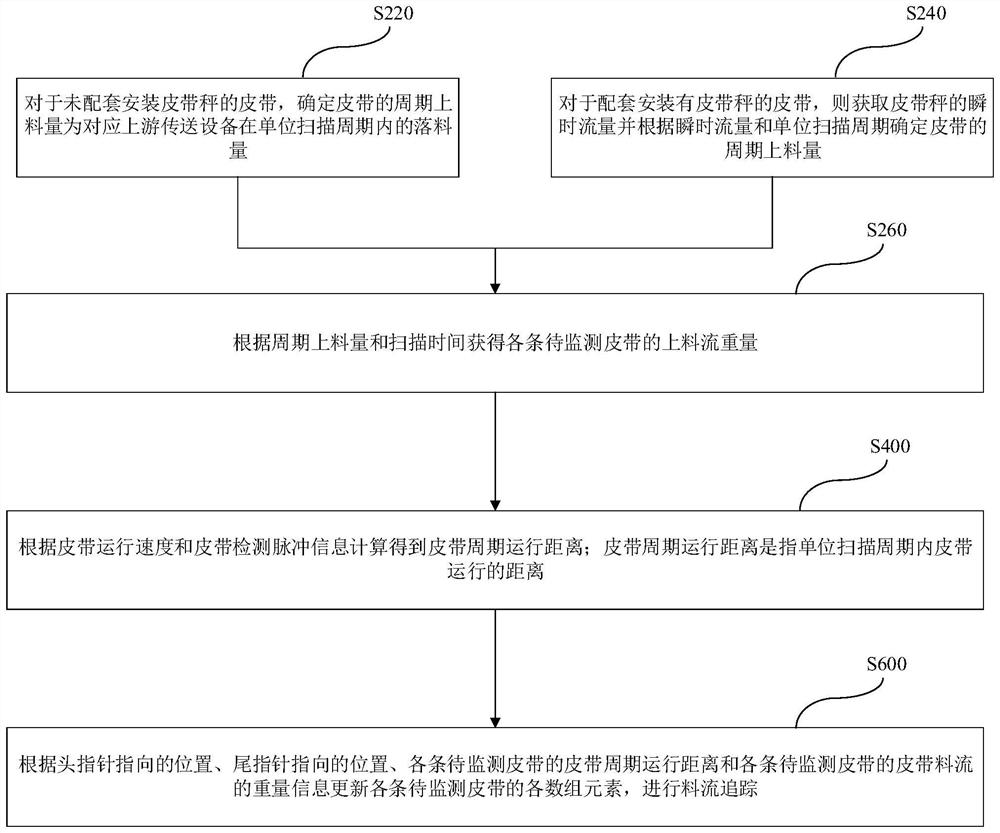

[0055] In one embodiment, as figure 2 As shown, an embodiment of the present application provides a method for tracking a material flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com