Low-torque valve element sleeve

A spool sleeve and low torque technology, which is applied in the field of spool sleeves and low torque spool sleeves, can solve problems such as not being able to meet low torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

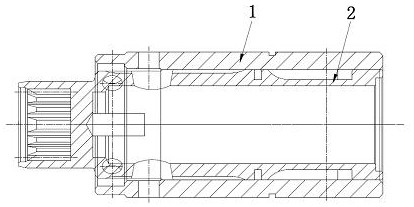

[0024] The low-torque valve core sleeve of this embodiment is a preferred embodiment. For the basic structure, please refer to figure 1 , which is composed of a valve core 2 with a transmission input at one end and a transmission output at the other end and a valve sleeve 1 sleeved outside it.

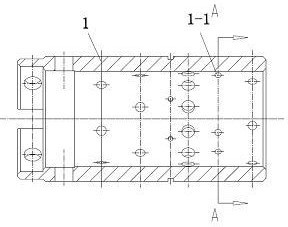

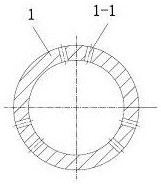

[0025] The specific structure of the valve sleeve 1 is as follows: Image 6 , Figure 7 As shown, there are seven groups of flow channel switching holes distributed at axial intervals, and the second row of flow channel switching holes adjacent to the transmission output end contains three pairs of circumferentially evenly distributed switching perforations 1-1 with a pair of two adjacent holes. The hydraulic pressure of the valve core sleeve is subject to hydraulic fluctuations, so the outer sides of the two adjacent holes are respectively added with transition holes 1-2.

[0026] The specific structure of valve core 2 is as follows Figure 8 , Figure 9 As shown, the outer circl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com