Functional double faced adhesive tape forming processing technology

A technology of forming processing and double-sided adhesive tape is applied in the field of processing technology to achieve the effect of saving manpower and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

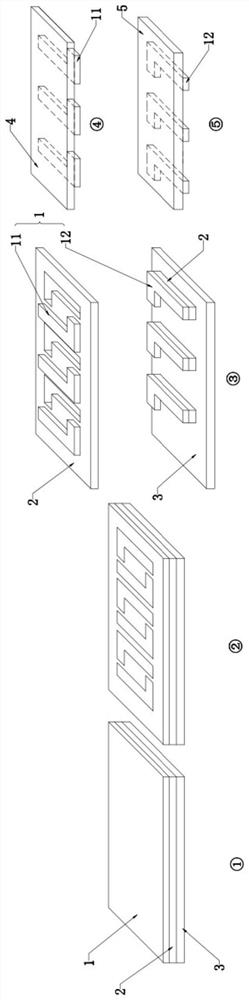

[0012] like figure 1 As shown, a functional double-sided adhesive forming processing technology, the technology includes the following steps:

[0013] Step 1: Adhere the double-sided adhesive tape 1, the first carrier film 2 and the second carrier film 3 in sequence to obtain a three-layer film finished product;

[0014] Step 2: The finished three-layer film in step 1 is punched by knife rollers with deep and shallow intervals to obtain the finished three-layer film punched to the 2nd side of the first carrier film and to the 3rd side of the second carrier film. Punch out three-layer film finished products;

[0015] Step 3: peel off the finished three-layer film punched in step 2 to obtain a two-layer film to be processed with the first double-sided tape 11 and the first carrier film 2 bonded, and the second double-sided tape 12 bonded with the film to be processed. , the three-layer films to be processed of the first carrier film 2 and the second carrier film 3 are separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com