Live-line working method for changing double-circuit line triangularly-arranged straight pole into strain pole

A technology of triangular arrangement and live operation, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of small wire spacing, large operation difficulty, large influence range, etc., to prevent changes in insulation gaps, ensure fixed quality, and simplify labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

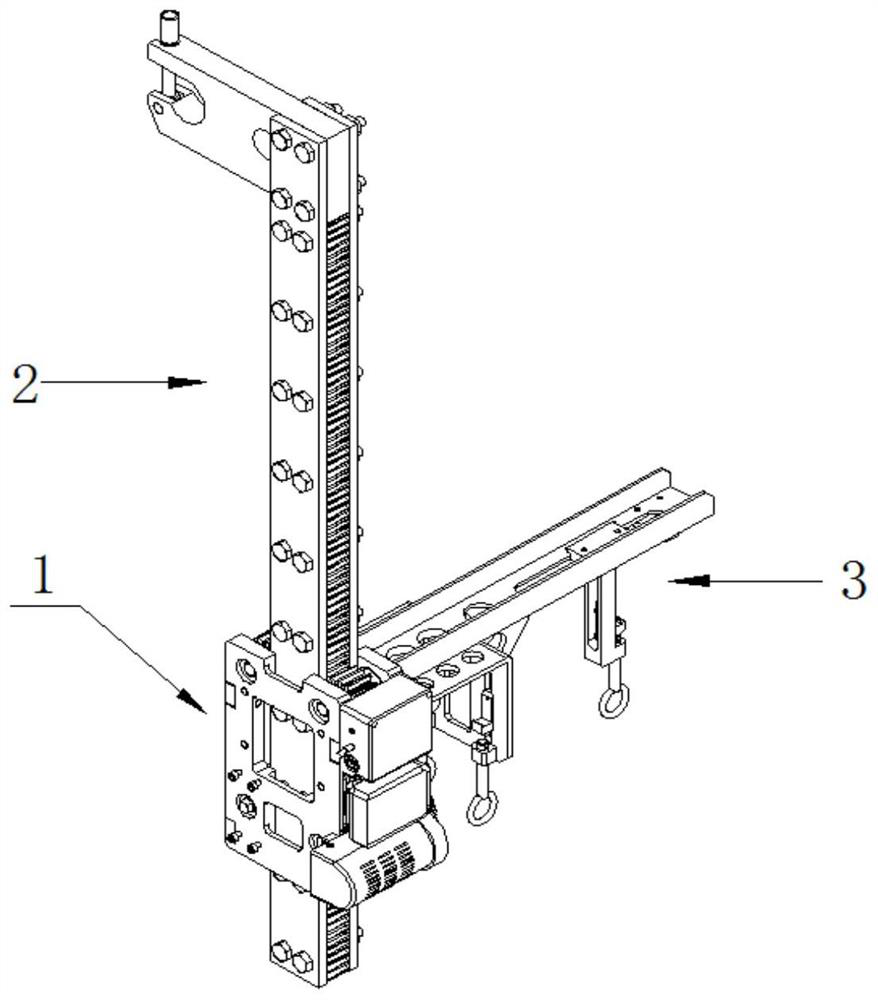

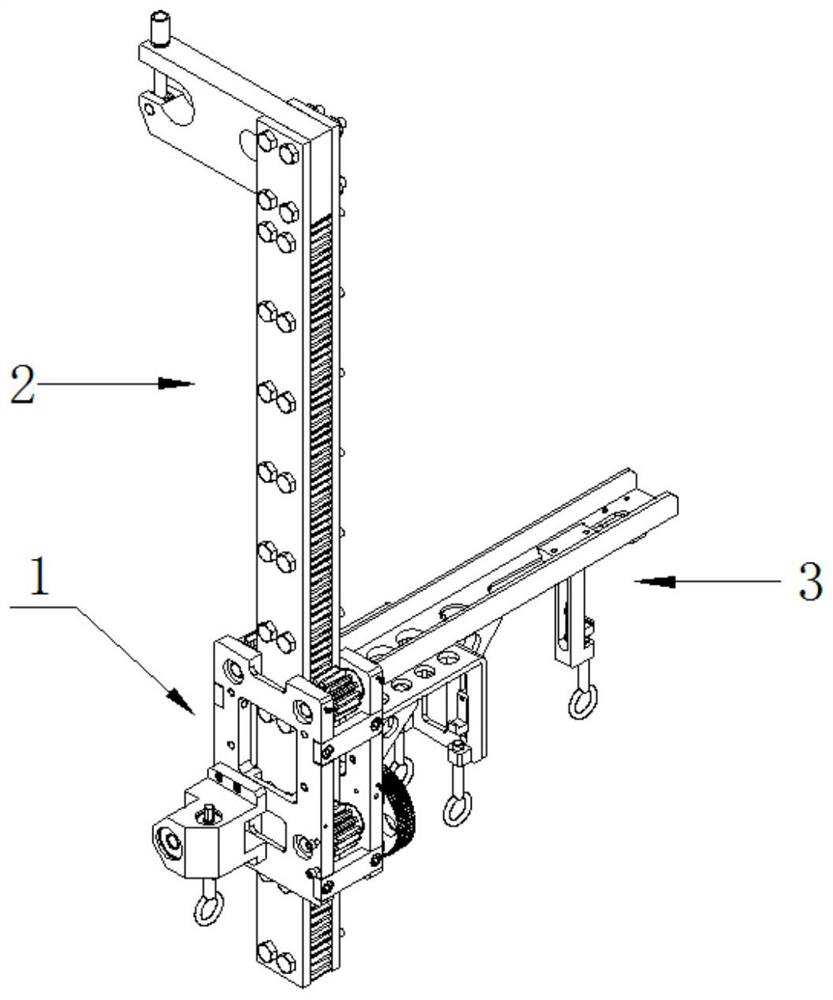

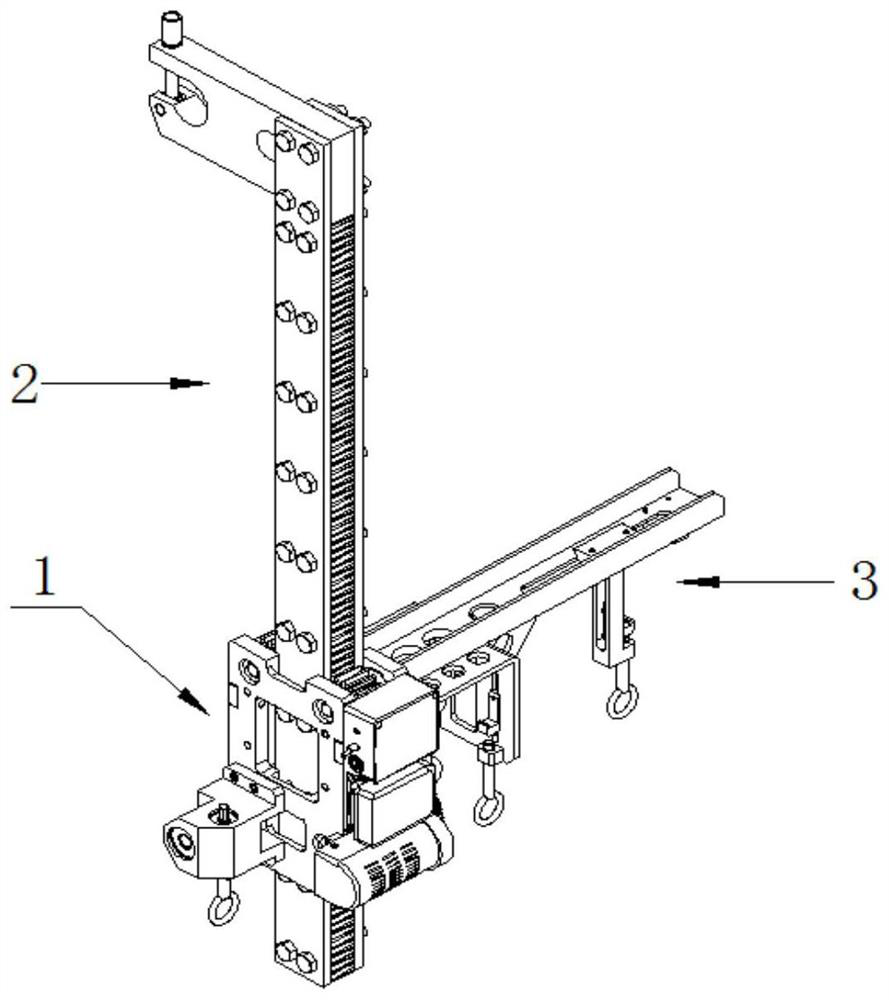

Image

Examples

Embodiment Construction

[0052] A live operation method for changing a tension rod from a triangularly-arranged linear rod to a double-circuit line, comprising the following steps:

[0053] S1: Adjust the insulation heads of the four insulation bucket trucks loaded with electricians to the position of the underside of the live wire cross arm of the linear pole to be transformed, that is, equip each circuit on the linear pole to be transformed with two insulation buckets Carry out the operation of changing the linear rod to the tension rod, and then use the electric inspection tool to conduct electric inspection of the insulators and cross-arms in each circuit on the linear rod to be modified to confirm whether there is any leakage phenomenon;

[0054] S2: The electrician located in one of the insulated bucket trucks equipped in each circuit shall follow the shielding principle of "from near to far, from bottom to top, first charged body and then grounded body" to all live charged parts within its worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com