Device for tension test of strain clamp wire assembly

A technology of tension clamps and assemblies, which is applied in the direction of measuring devices, applying stable tension/pressure to test material strength, instruments, etc., can solve the problem that the tension clamp wire assembly is easy to detach, easy to rotate by mistake, and affect the test Results and other issues, to achieve the effect of reducing shaking, ensuring the quality of fixing, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

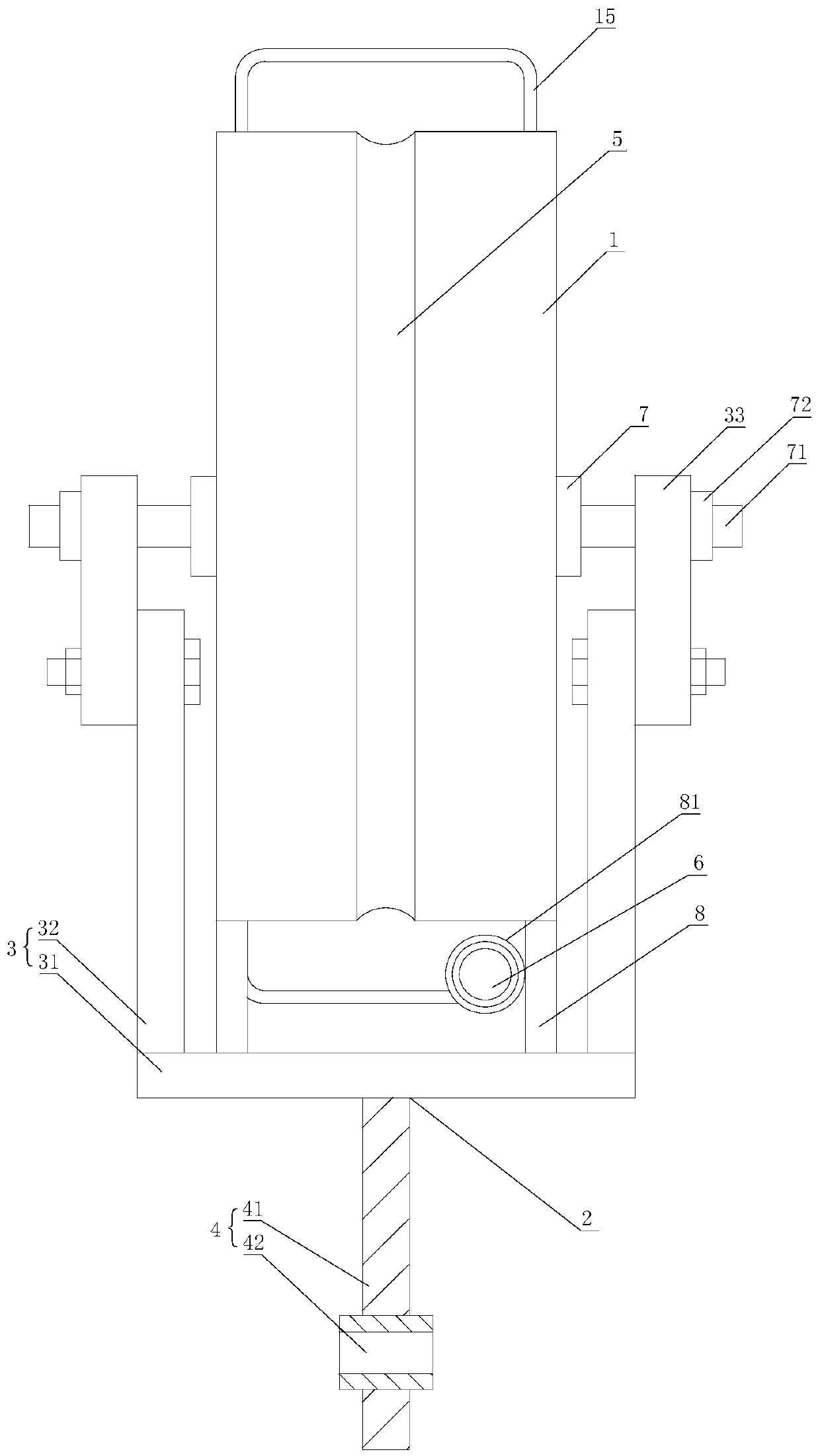

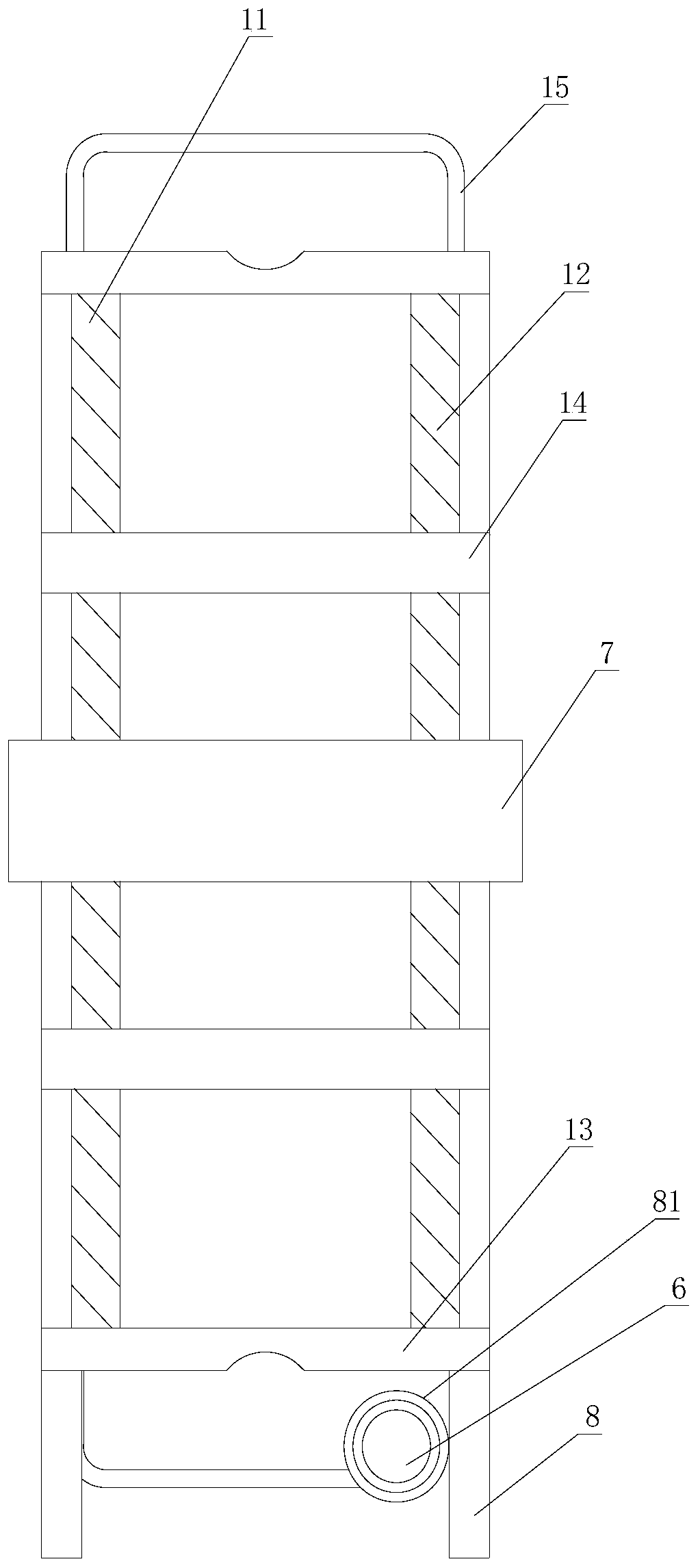

[0017] Such as figure 1 , figure 2 As shown, a device for the tension test of the tension clamp wire assembly includes a spoke 1 and a connecting piece 2, and the connecting piece 2 includes a first connecting part 3 connected to the spoke 1, and a section connected to the tensile force The second connecting part 4 connected to the fixed end of the testing machine, the second connecting part 4 is arranged on the first connecting part 3, and the spoke 1 also includes a rotating shaft 7, and the first connecting part 3 is arranged on the rotating shaft 7 Connected screw rod 71, the screw rod 71 is locked on the first connecting part 3 through the lock nut 72 after passing through the first connecting part 3, and the outer circumferential side wall of the spoke 1 is provided with an annular recess for fixing the sample. Groove 5, and the guide sleeve 6 that is convenient for the sample to pass through, and the sample is connected to the loading end of the tensile testing machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com