An insulating protective cover installed without power failure

A technology of insulation protection and insulation cavity, applied in the direction of the board/panel/desk of the substation/switchgear, etc., can solve the problems of single-phase grounding or phase-to-phase short circuit, line fault tripping, inability to meet the distribution line, and reduce the number of operations. and the number of people, release the construction force, and shorten the installation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

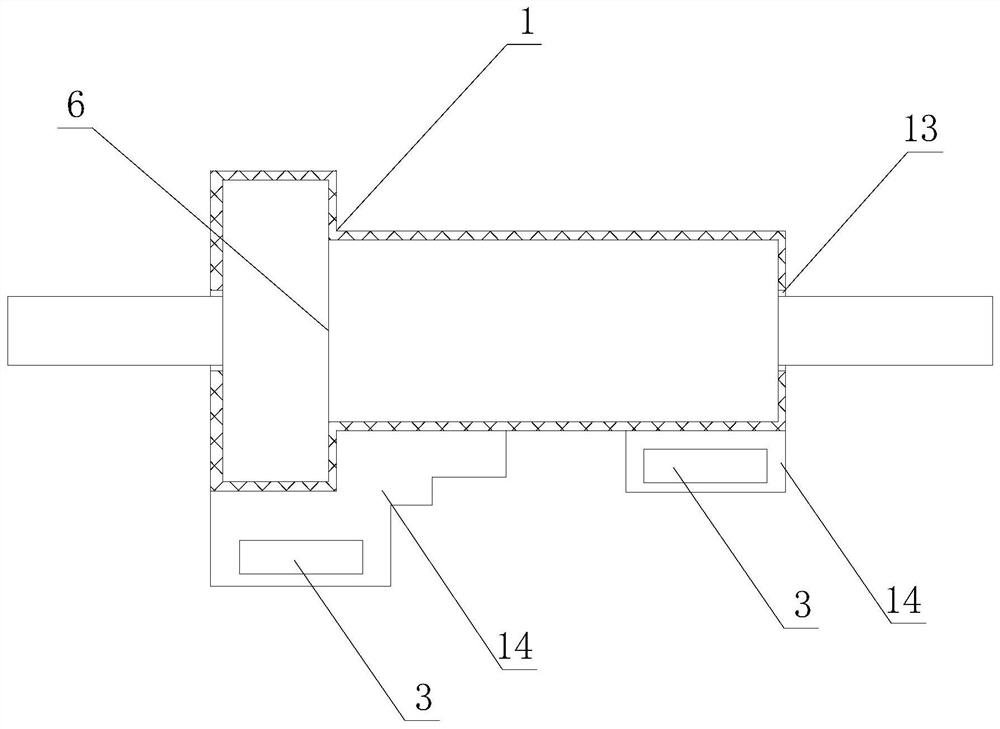

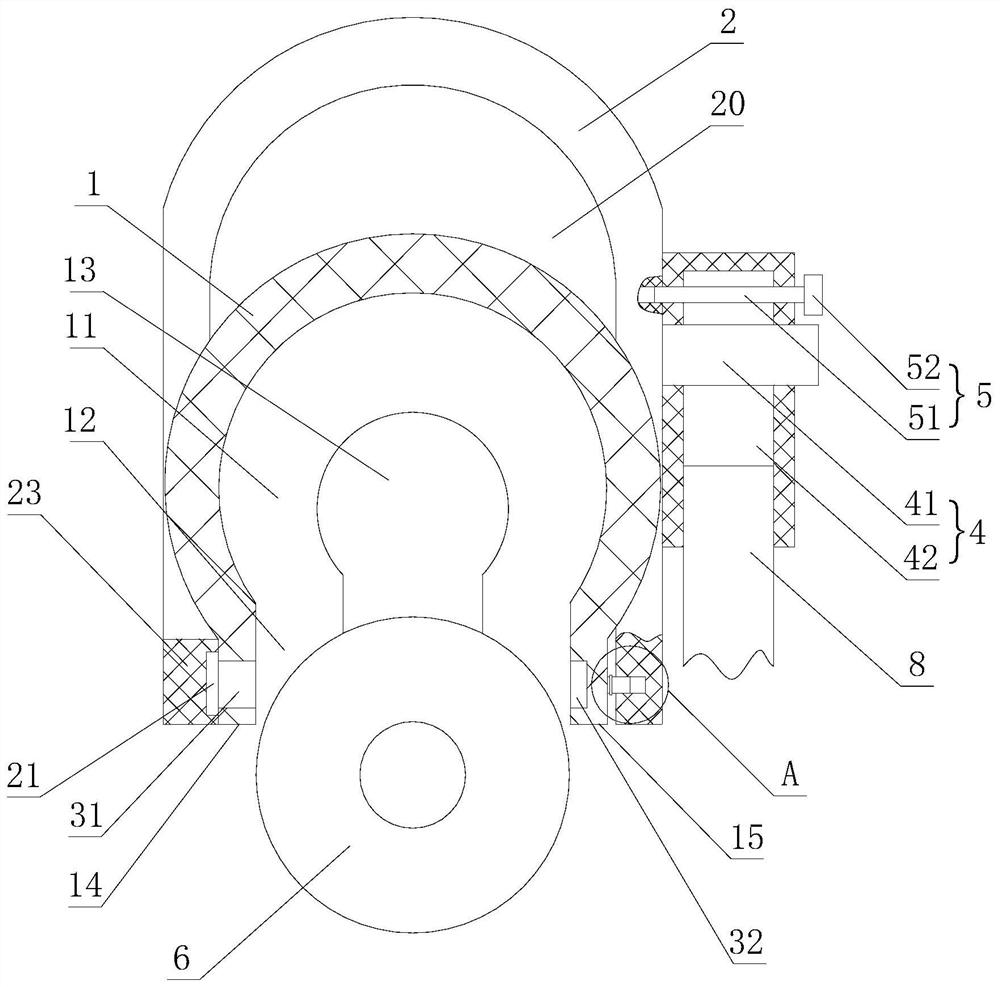

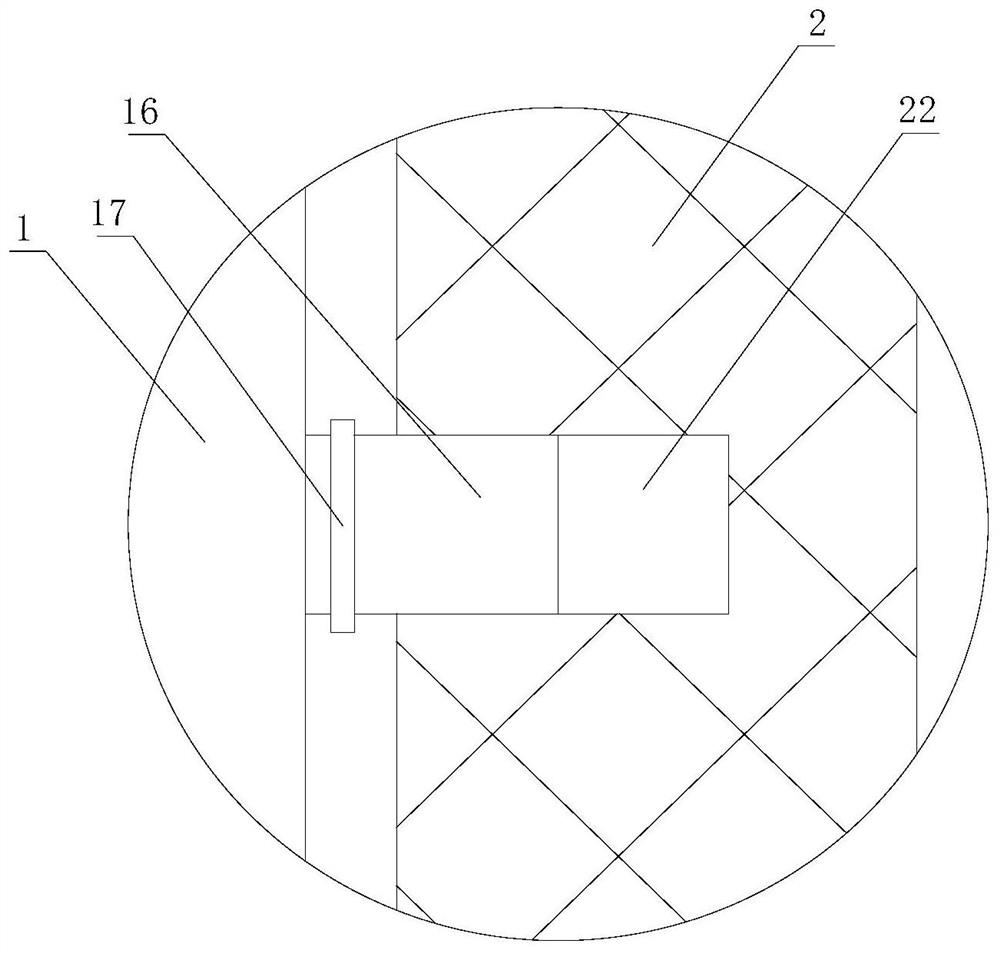

[0022] like figure 1 , figure 2 , image 3 , Figure 4 As shown, an insulating protective cover that is installed without power failure includes a heat-shrinkable silicone rubber body 1 and an insulating actuator 2. The heat-shrinkable silicone rubber body 1 is provided with an insulating cavity 11 that wraps the switch 6 on the column along the length direction. The bottom end of the insulating cavity 11 is provided with an opening 12 , the side walls of both ends of the insulating cavity 11 are provided with mounting holes 13 which are matched with the wires of the switch on the post, and the heat shrinkable silicone rubber body 1 is provided with an opening 12 . There is a magnetic connection structure 3 to prevent the heat-shrinkable silicone rubber body 1 from disengaging. The heat-shrinkable silicone rubber body 1 is detachably mounted on the insulating actuator 2, and the insulating actuator 2 is provided with a connecting rod 8 The rotating body 4 can be rotated 36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com