Hook tail frame hot working tool

A hook tail frame and thermal processing technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of small transfer volume, long hook tail frame transfer cycle, long position adjustment time, etc., and achieve stacking efficiency. The effect of improving, shortening the stacking and loading time, and being less restrictive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is a further detailed description through specific embodiments:

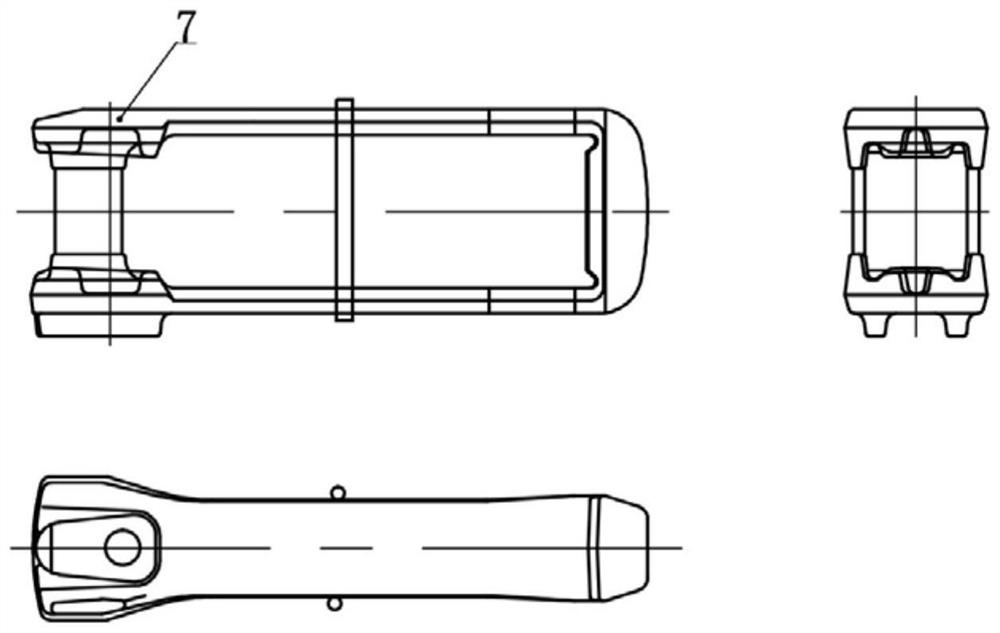

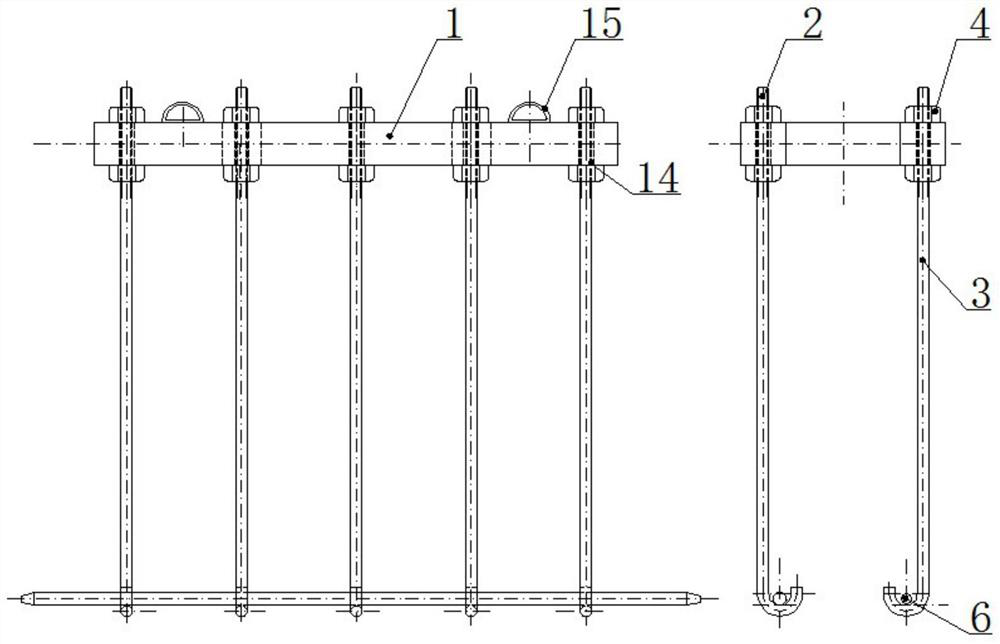

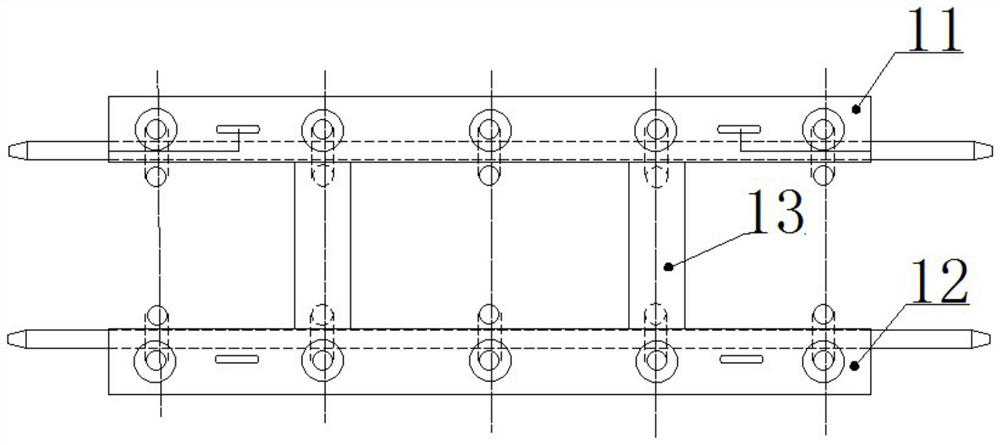

[0032] The symbols in the accompanying drawings include: fixed arm 1, left fixed arm 11, right fixed arm 12, connecting rod 13, threaded hole 14, lifting lug 15, left fixed rod 2, right fixed rod 3, nut 4, hook-shaped protrusion Lifting 5, support rod 6, hook tail frame 7.

[0033] The example is basically as attached figure 2 , image 3 shown:

[0034] A hook-tail frame thermal processing tooling includes a fixed arm 1, a fixed rod and a support rod 6; the fixed arm 1 includes a left fixed arm 11 and a right fixed arm 12; the left fixed arm 11 and the right fixed arm 12 are fixedly connected There are connecting rods 13 ; in this embodiment, there are two connecting rods 13 , which are rectangular plates with the same height as the fixed arm 1 . A lifting lug 15 is fixed on the top surface of the fixed arm 1 . The lifting lugs 15 are provided with a plurality of groups and are symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com