Plant monitoring method, device and equipment

A plant and equipment technology, applied in agriculture-related fields, can solve the problems of high labor costs, achieve real-time monitoring of growth status, save on-site inspection management and artificial planting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

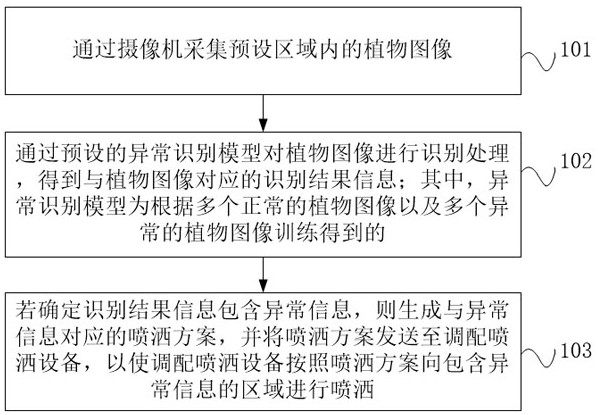

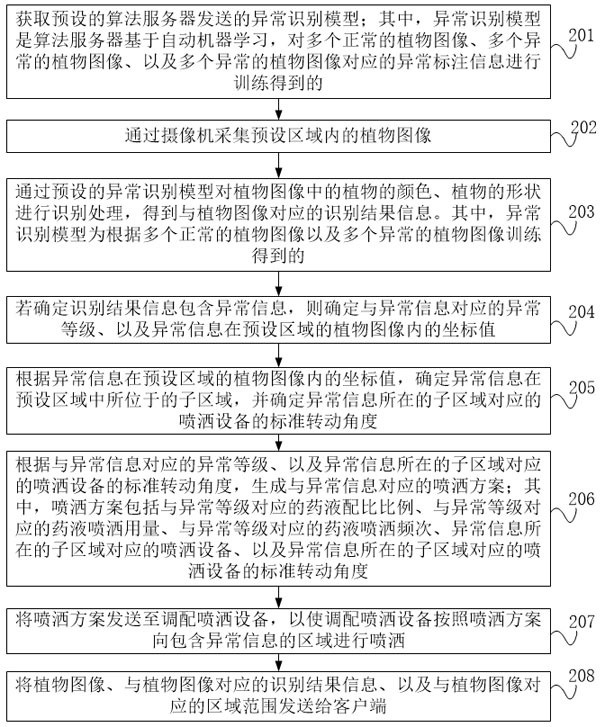

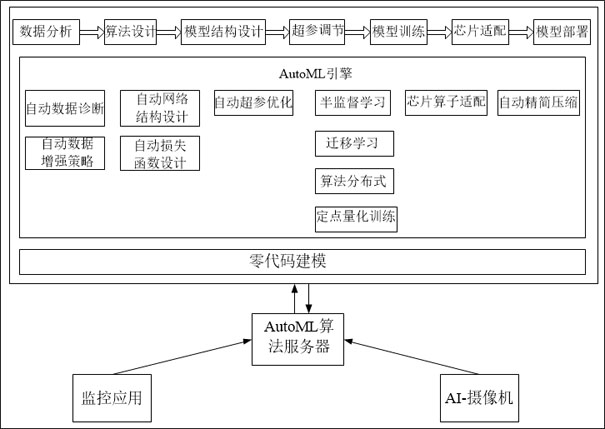

Method used

Image

Examples

Embodiment Construction

[0111] Exemplary embodiments will be described in detail herein, examples of which are illustrated in the accompanying drawings. Where the following description refers to the drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated. The implementations described in the illustrative examples below are not intended to represent all implementations consistent with this disclosure.

[0112] At present, in order to better manage the growth conditions of plants in large-scale planting areas, a large number of planters are usually required to maintain, but there are many problems in the maintenance process of planters.

[0113] In one example, in the planting area of each region, a large number of planters are required to inspect the growth state of the plants, and fertilize, irrigate, and remove pests and other operations on the plants according to the planters' subjective wishes. However, in the prior art, since a large n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com