Stop hydraulic driving device of stainless steel plate

A technology of driving device and stainless steel plate, which is applied in transportation and packaging, parts of grinding machine tools, metal processing equipment, etc., and can solve the problem of no stop drive structure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below, the present invention will be described in detail with reference to the accompanying drawings and embodiments:

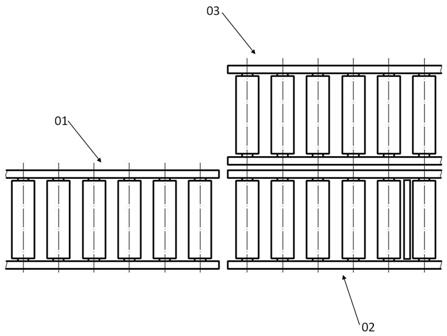

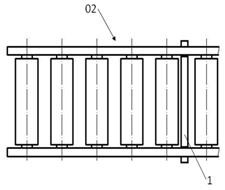

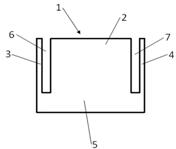

[0036] like Figures 1~6 As shown in the figure, a stop-stop hydraulic drive device for stainless steel plates includes a No. I distribution roller group 02, and the I No. A lifting baffle 1 is arranged between the two conveying rollers, and a left driving box 8 and a right driving box 9 are respectively arranged on both sides of the lower part of the lifting baffle 1. The left driving box 8 and the right driving box 9 are in Both are provided with a drive cylinder 11, and the cylinder rod of the drive cylinder 11 protrudes out of the left drive box 8 and the right drive box 9 vertically.

[0037] Ribs 10 for reinforcement are provided between the left drive case 8 , the right drive case 9 and the lift baffle 1 .

[0038] The left driving box 8 and the right driving box 9 are both in the shape of an indentation, and the left driving box 8 and the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com