Line dropping prevention device for photovoltaic solder strip equipment

A technology for photovoltaic welding strips and equipment, which is applied in the field of anti-dropping devices for photovoltaic welding strip equipment, can solve the problems of loosening photovoltaic welding strips, falling photovoltaic welding strips, reducing production efficiency, etc. Reduce workload and avoid dropped calls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

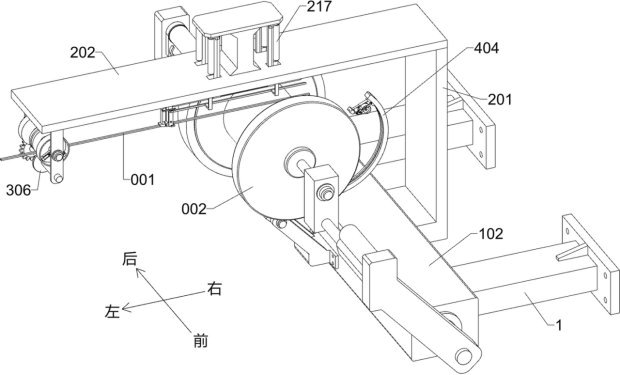

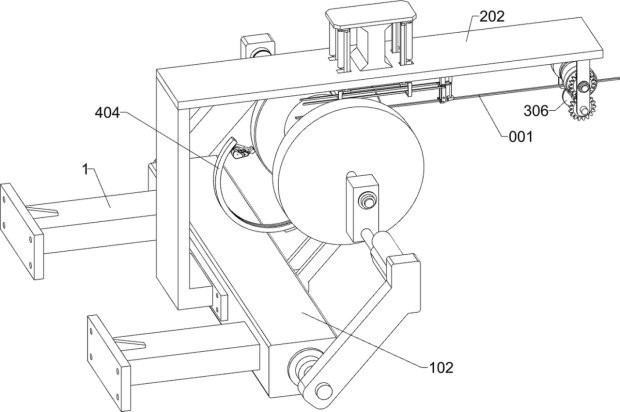

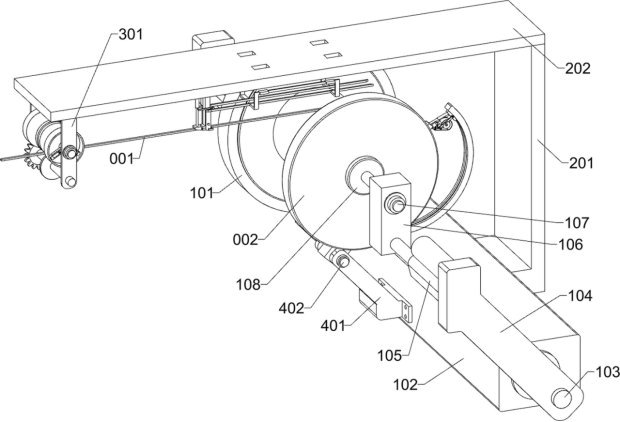

[0030] An anti-drop device for photovoltaic ribbon equipment, such as Figure 1-10 As shown, it includes a support plate 1 and a wire take-up assembly; the left side of the two support plates 1 is installed with a wire take-up assembly;

[0031] It also includes a fixing plate 310, a pulling assembly, a fixing assembly and an adhesive assembly; a pulling assembly is installed on the right side of the wire take-up assembly; a fixing assembly is installed on the left part of the pulling assembly; an adhesive assembly is installed on the left side of the wire take-up assembly; Two fixed disks 310 which are symmetrical in front and rear are connected.

[0032] The wire take-up assembly includes a limit plate 101, a first fixed plate 102, a first electric rotating shaft 103, a transmission plate 104, a first electric push rod 105, a fixed block 106, a second electric rotating shaft 107 and a wafer 108; two support plates 1. A first fixing plate 102 is welded together on the left sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com