Test tube placing rack

A technology for placing racks and test tubes, which is applied in the field of placing racks, which can solve the problems of broken test tubes and unreliable test tubes, etc., and achieve the effect of firm fixation and increased fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

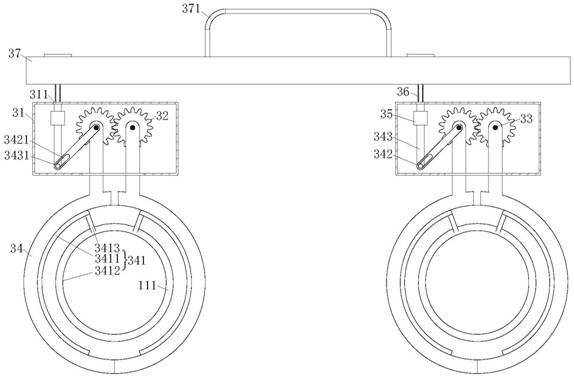

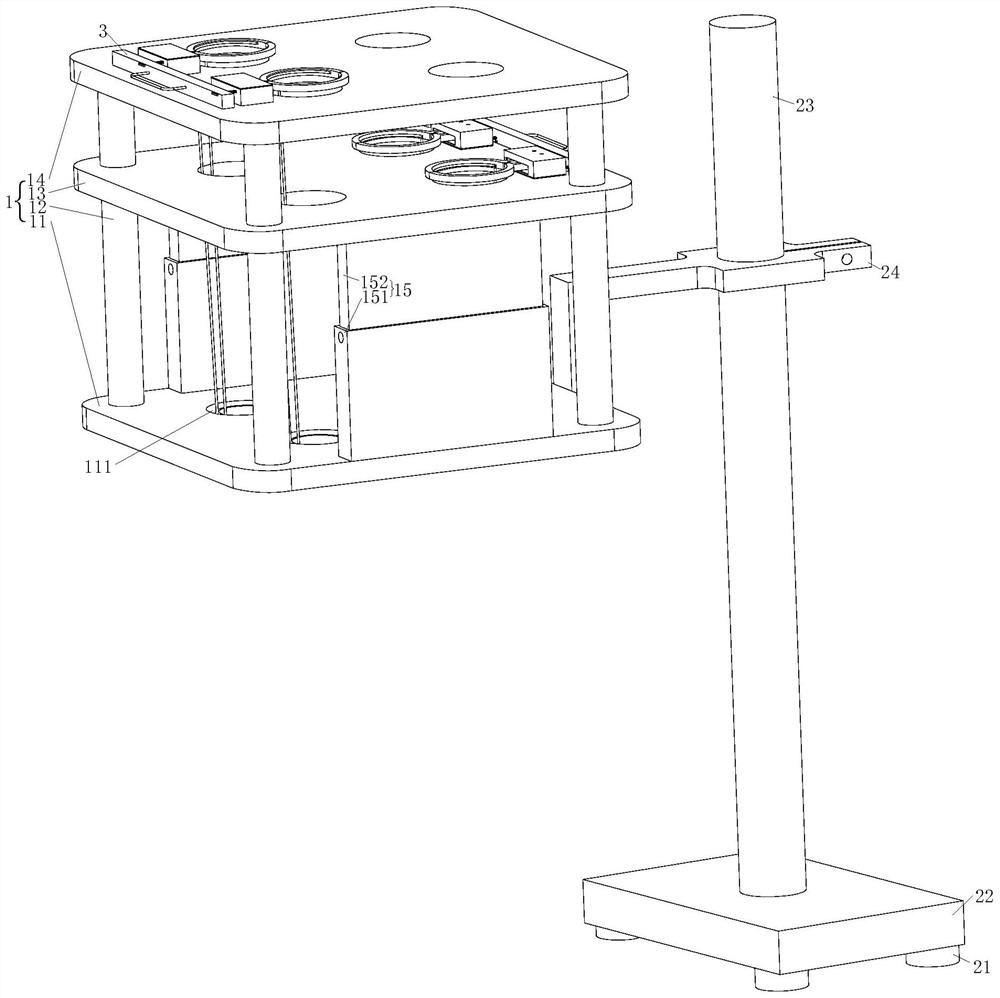

[0030] As a specific embodiment of the present invention, the support frame 2 includes a magnetic suction cup 21, a base 22, an adjustment rod 23 and a moving plate 24, and the magnetic suction cup 21 is fixed at four corners below the base 22;

[0031] The adjusting rod 23 is fixed above the base 22 , the moving plate 24 is provided with threaded holes, and the moving plate 24 is fixed to the adjusting rod 23 through a threaded connection.

[0032]Before fixing the test tube, the support frame 2 is placed on the metal table top, the magnetic suction cup 21 sucks the table top, the support frame 2 is fixed with the metal table top, and each of the four corners under the base 22 is provided with a magnetic suction cup 21 to increase the stability effect. The movable plate 24 is fixed on the lower end of the bottom plate 11, so the placing frame 1 moves with the movement of the movable plate 24, and the sliding connection is used to realize the up and down movement of the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com