Gravure mark setting method

A mark and white technology, applied in the field of multi-color registration, can solve the problems of automatic registration, white color group mark cannot be recognized, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the purpose, structure and function of the present invention, a method for setting a gravure mark of the present invention will be described in further detail below with reference to the accompanying drawings.

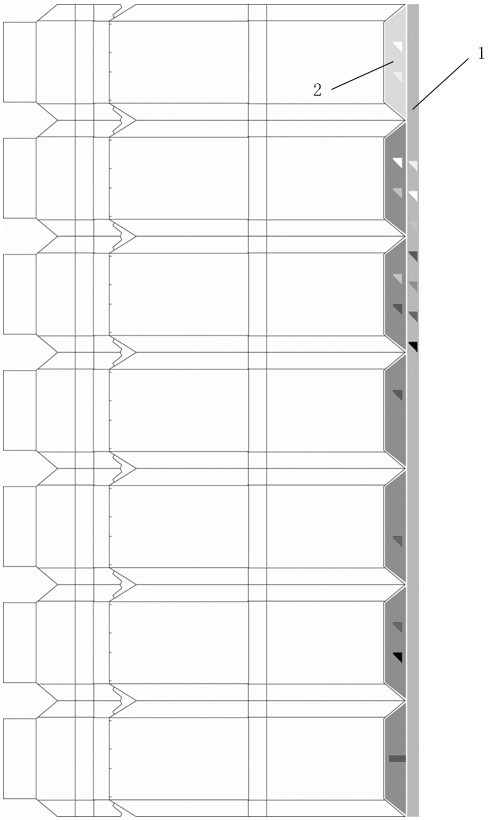

[0017] like figure 1 Shown is a printed product, the existing mark printing method is to leave a mark edge 1 at the edge of the printed matter, and the mark edge 1 is silver or white. When the first color is white, the mark edge 1 selects silver, and when the first color When the color is light, in order for the sensor to recognize the mark, the mark side 1 is selected as white. At this time, if a white color group appears, the white mark cannot be recognized on the white background, and automatic positioning cannot be realized.

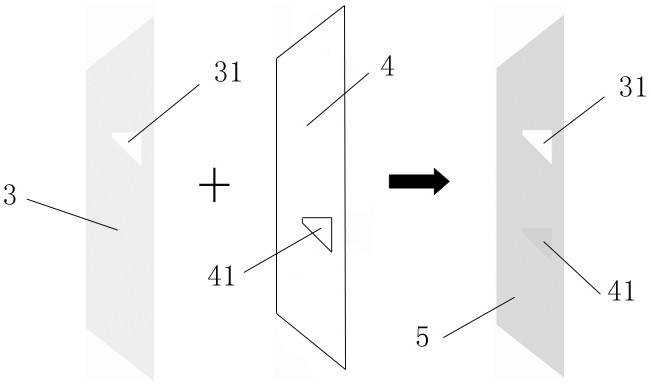

[0018] Based on this, the present invention has been improved, and a method for setting a gravure mark of the present invention does not require setting a mark edge 1, and only needs to make a mark on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com