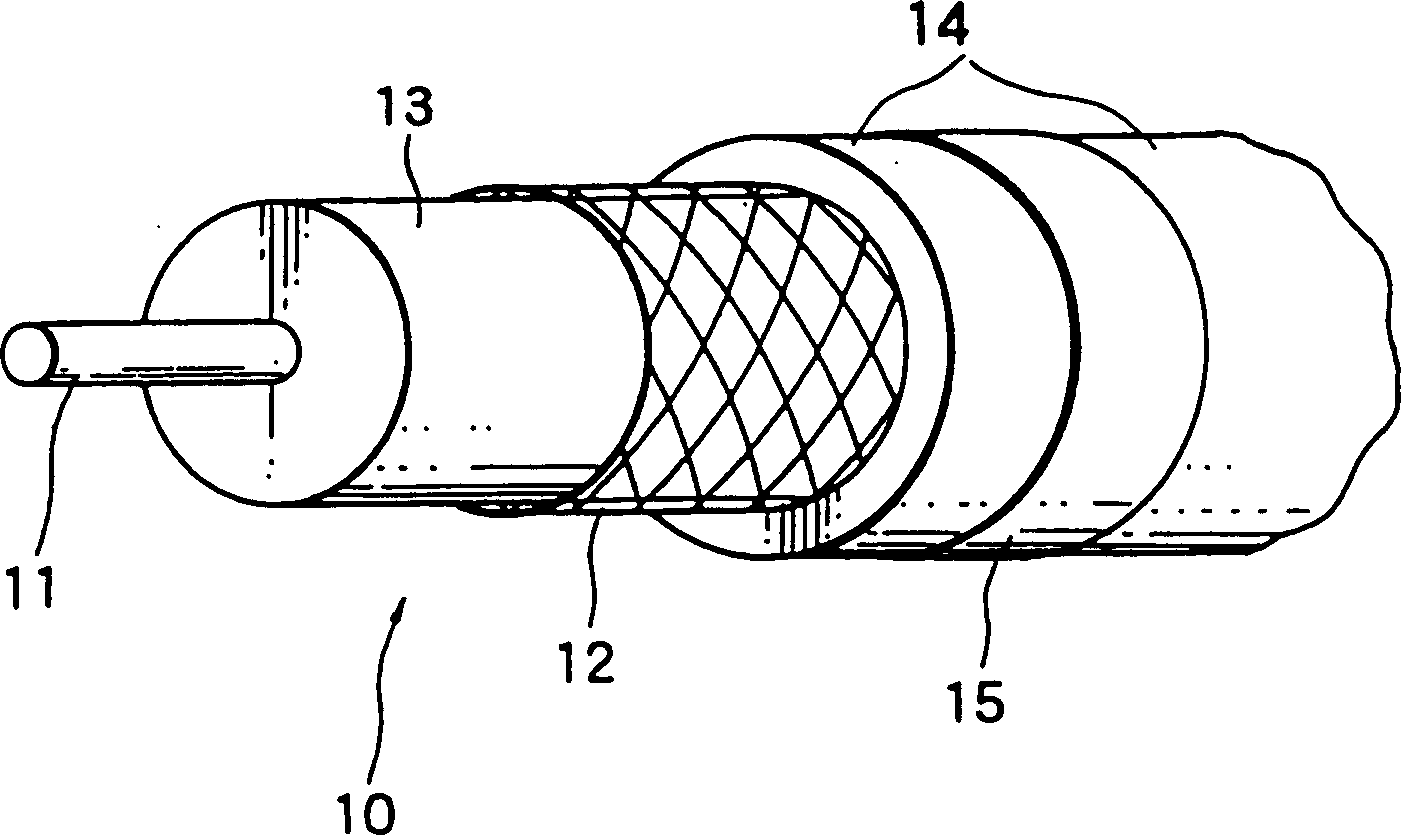

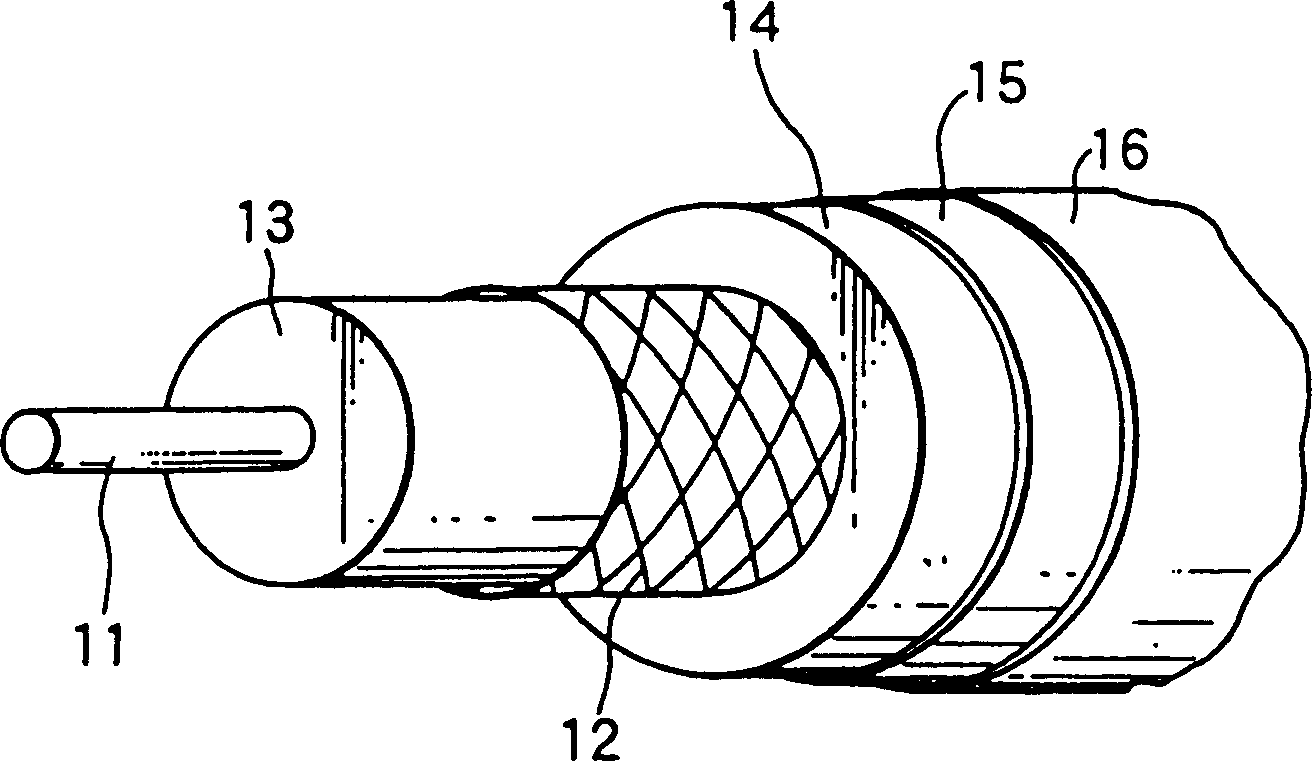

Signal transmission cable with noise absorption high loss magnetic film formed on cable sheath

A technology of signal transmission and high loss, which is applied in the direction of coaxial cable/analog cable, insulated cable, communication cable, etc., and can solve the problems of impracticality, poor magnetic characteristic and frequency characteristic, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

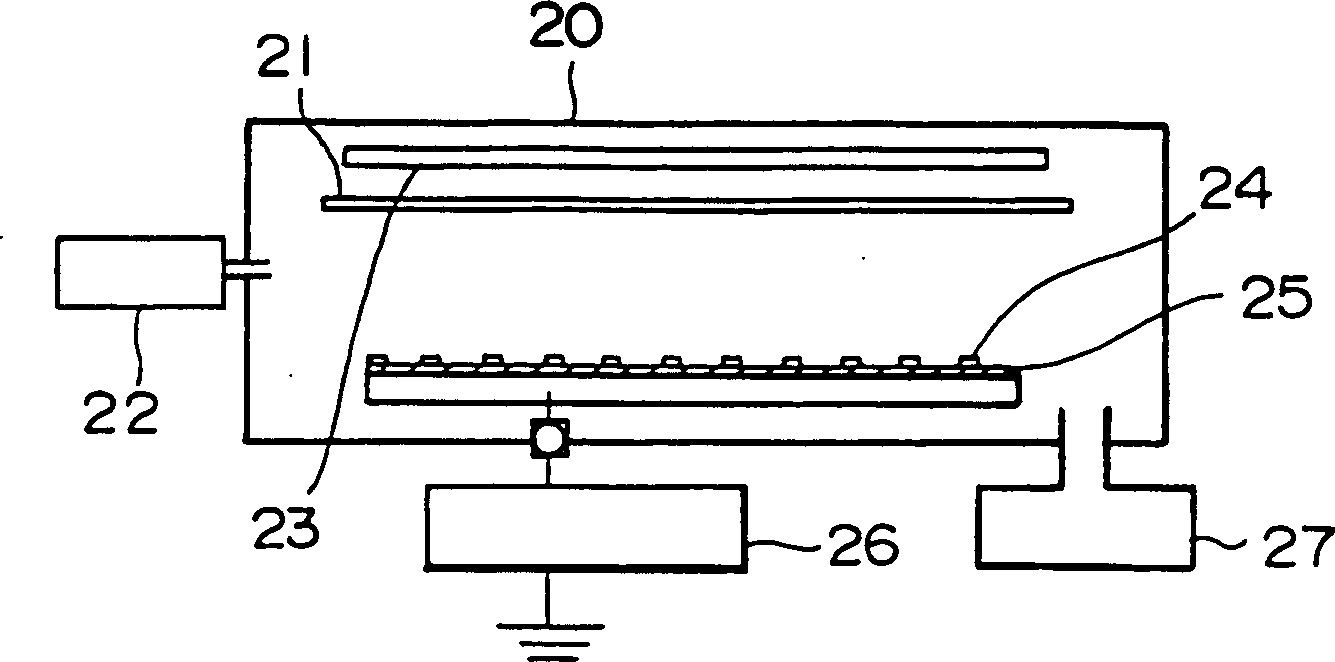

Method used

Image

Examples

example 2

[0069] Under similar conditions to Example 1, but using 150Al 2 o 3 Chip, Film Sample 2 was formed on a glass substrate.

[0070] The obtained film sample 2 was analyzed by fluorescent X-ray spectroscopy, and it was confirmed that the composition was Fe 44 Al 22 o 34 membrane. The film sample 2 has a thickness of 1.2 μm, a DC characteristic impedance of 2400 μΩ·cm, an anisotropic field strength (Hk) of 120 Oe, and a saturation magnetic field strength (Ms) of 9600 Gauss.

[0071] The percentage of the saturation magnetic field strength of film sample 2 to that of metal M itself, expressed as {Ms(M-X-Y) / Ms(M)}, is equal to 44.5%.

[0072] The μ"-f response of membrane sample 2 was obtained in a similar manner to Example 1, shown in Figure 4A . Note that the peak has a high value similar to film sample 1. However, the frequency point of the peak, or the natural resonant frequency, is about 1 GHz, and the complex permeability decreases gradually on both sides of the peak,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Characteristic impedance | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com