Crank shaft and method for manufacturing same

A crankshaft and axis technology, which is applied in the manufacturing field of crankshafts composed of multiple pieces, can solve problems such as abandonment, high tolerances of the main shaft and crankpin being parallel to each other, and failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

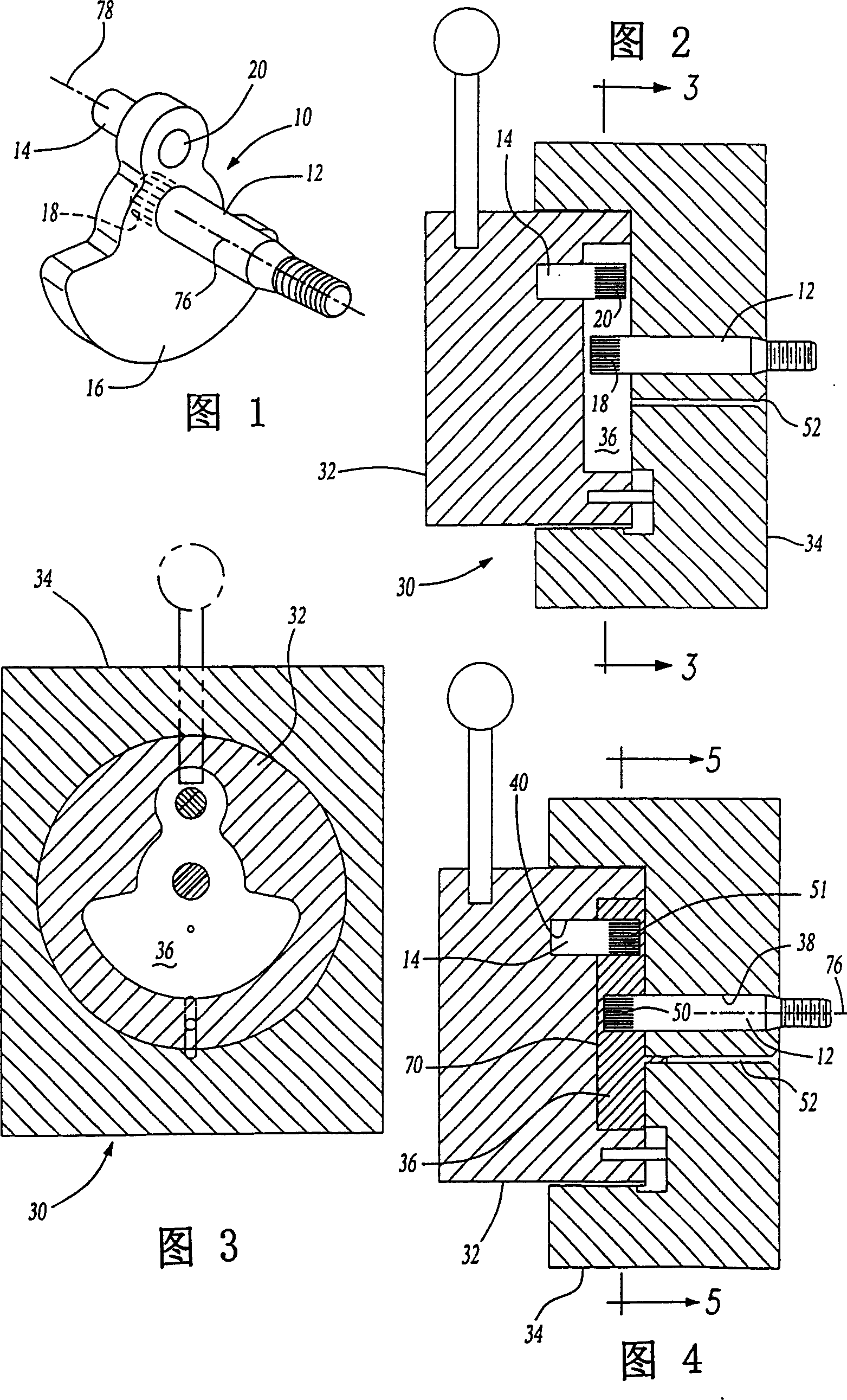

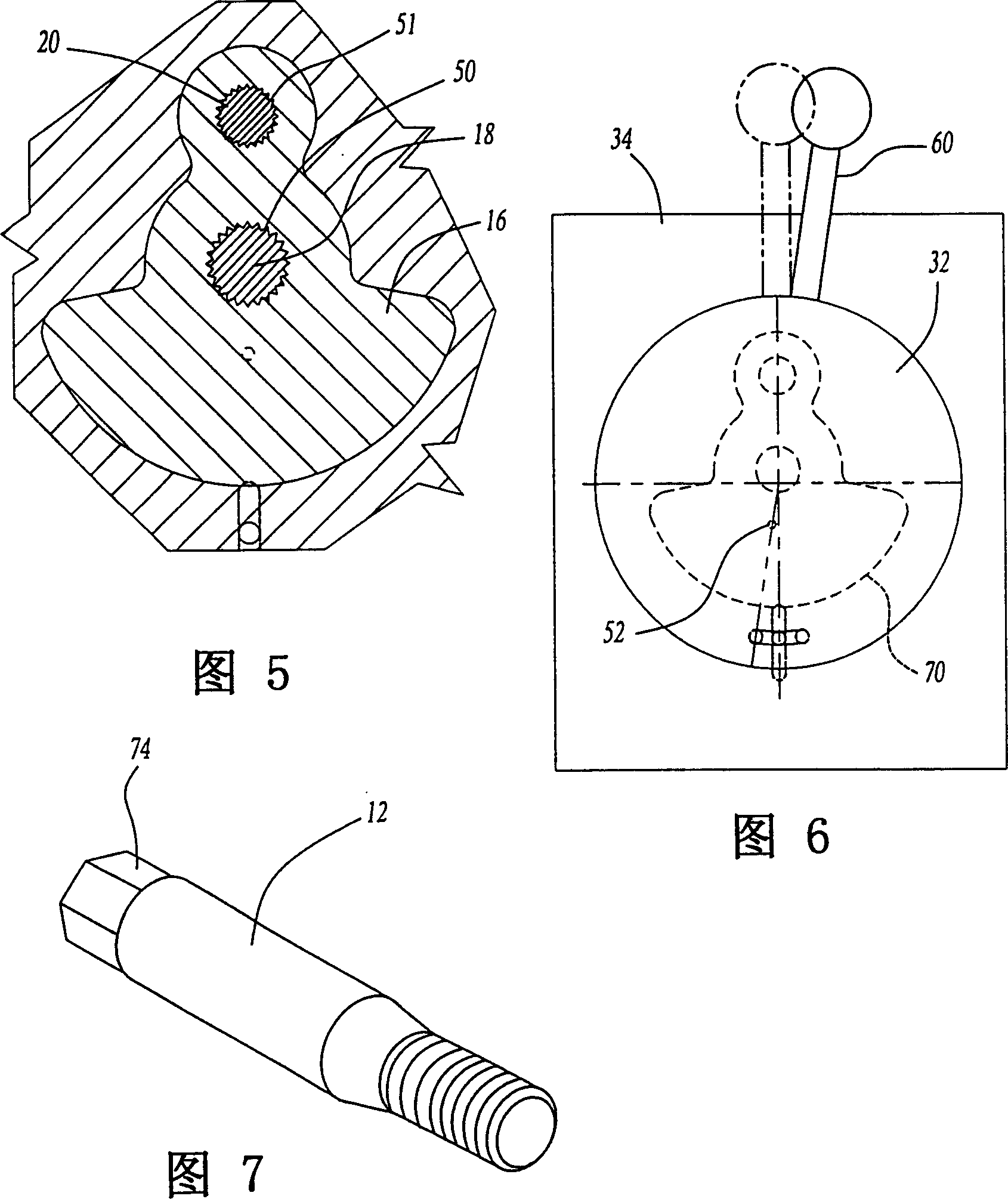

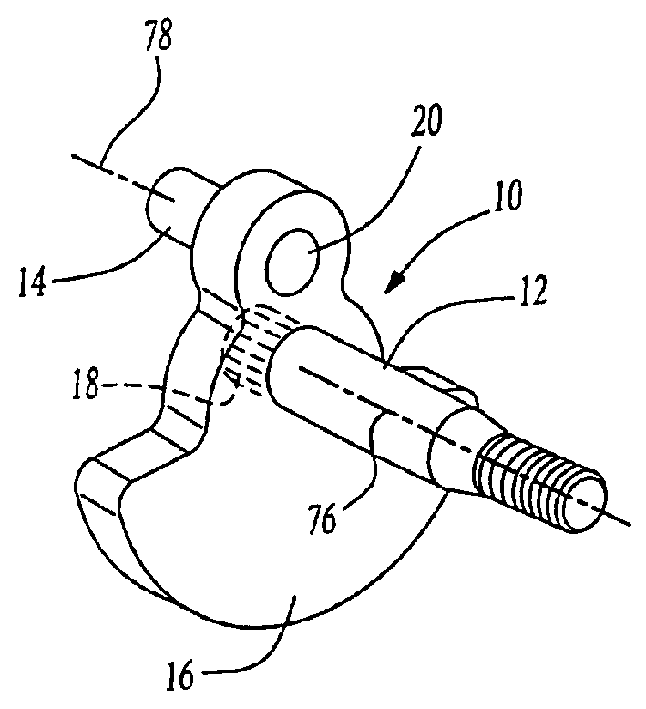

[0018] Referring to Figure 1, a preferred embodiment of the crankshaft 10 of the present invention is shown. The crankshaft has an elongated main shaft 12 adapted for rotation about its longitudinal axis and a crankpin 14 whose longitudinal axis is parallel to but radially spaced from the main shaft 12 .

[0019] A counterweight 16 extends between an end 18 of the main shaft 12 and an end 20 of the crank pin 14 . A counterweight 16 secures the crankpin 14 and main shaft 12 together in well known fashion.

[0020] Referring now to FIGS. 2-4, the crankshaft of the present invention is formed by casting a thermosetting material, preferably a liquid metal such as zinc, around the aligned ends 20 and 18 of the crank pin 14 and main shaft 12 during casting of the counterweight 16. 10. As best shown in FIG. 2, model 30 has two half-moulds 32 and 34 which are movable in a closed position shown in solid lines in FIG. 2 and an open position shown in dashed lines. When the molded part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com