System of recognizing quality of amphisarca in high speed based on machine vision

A machine vision and recognition system technology, applied in the field of agricultural machinery, can solve the problems that do not involve high-speed and real-time collection of inspected melons and fruits, and achieve the effect of increased speed and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

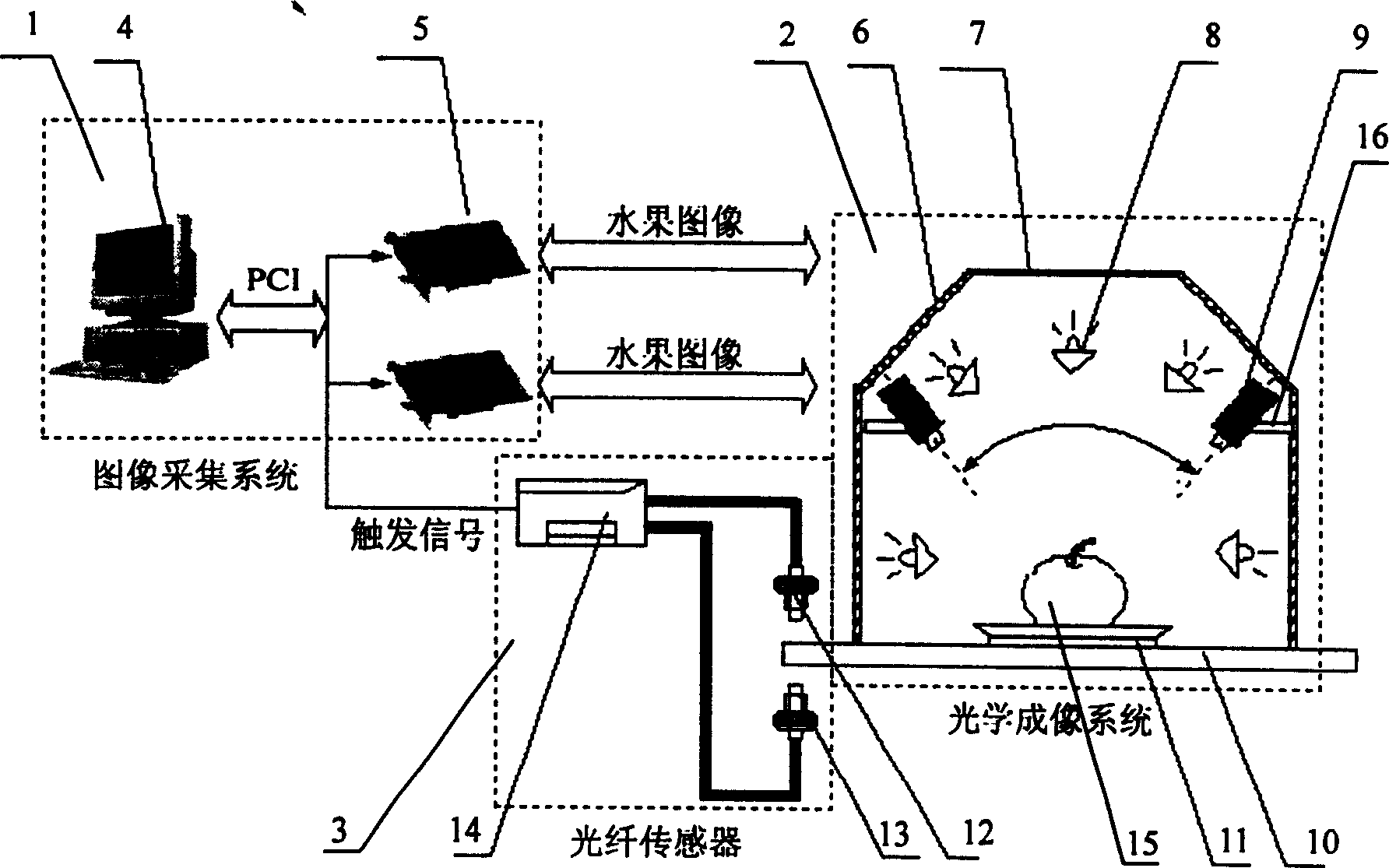

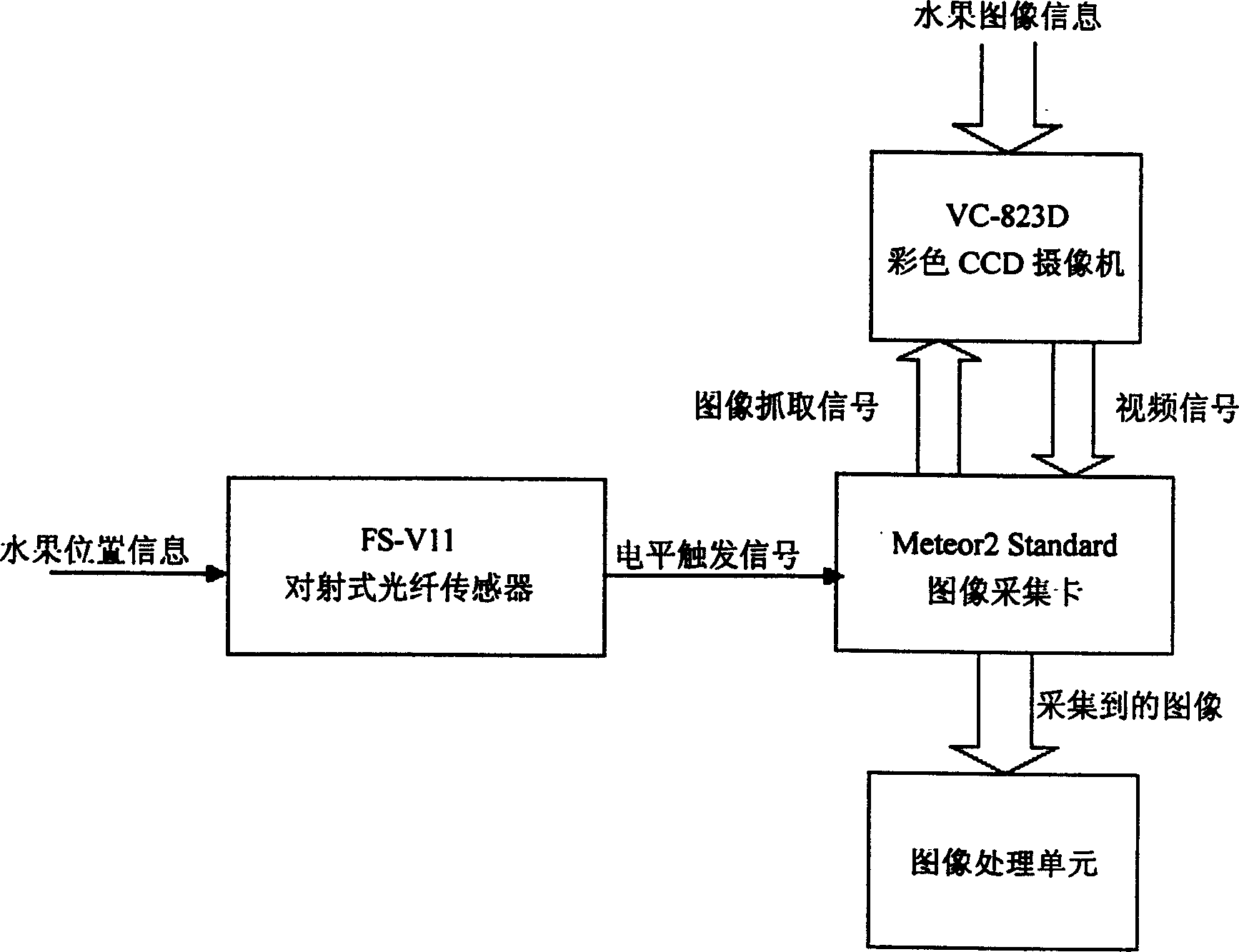

[0018] Whole melon and fruit quality recognition system structure of the present invention is as follows figure 1 As shown, it consists of three parts: an image acquisition system 1 , an optical imaging system 2 and an optical fiber sensor 3 .

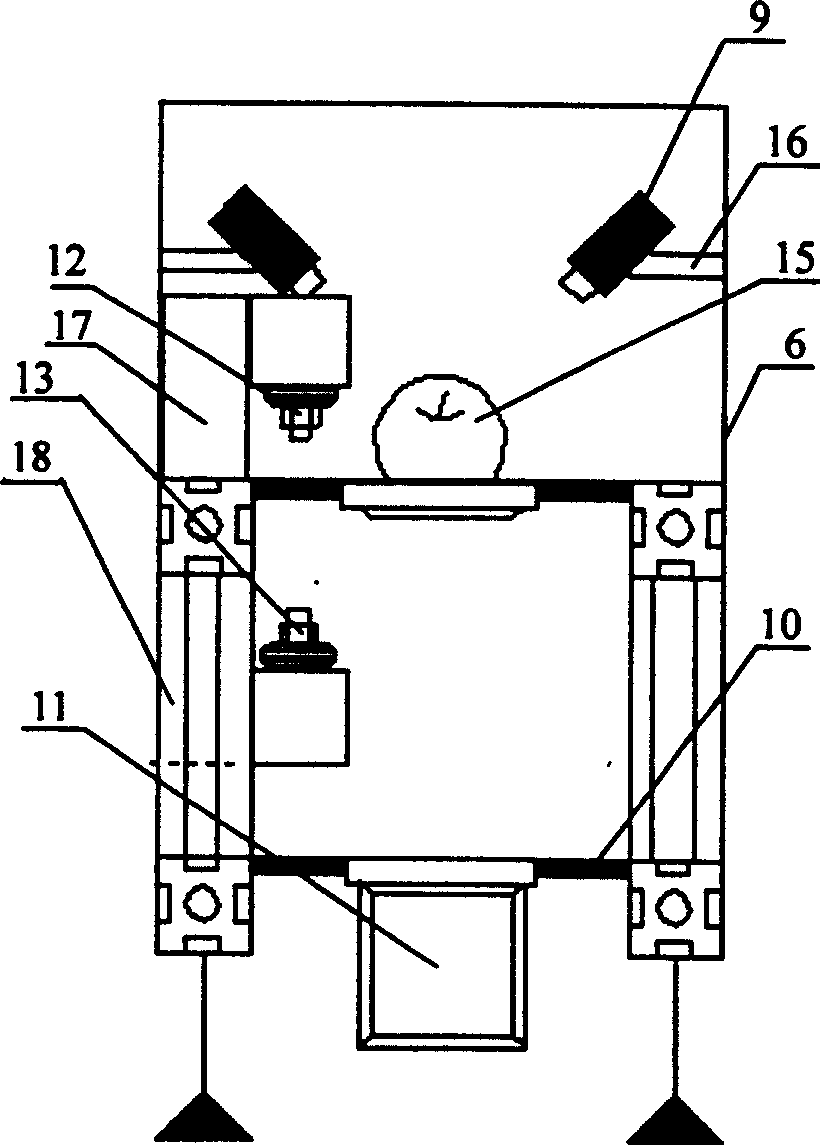

[0019] The optical imaging system 2 includes a light box housing 6 , a 220V lighting point light source 8 , a scattering ground glass 7 , a color CCD camera 9 , and a camera bracket 16 . Two cameras 9 are symmetrically installed on the camera bracket 16 fixed on the top of the light box shell 6, the angle between the cameras 9 is 120 degrees, and the normal distance to the surface of the fruit 15 to be checked is 15-20 cm. While ensuring the acquisition of complete fruit surface image information, image distortion caused by too close a distance between the fruit 15 and the camera 9 can be effectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com