Gas collection method and apparatus thereof

A technology of gas and collector, which is applied in the field of gas collection and gas collection devices, and can solve the problem of difficult recovery of gas components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Referring now to the accompanying drawings, a gas collection method and a gas collection device according to embodiments of the present invention will be described in detail.

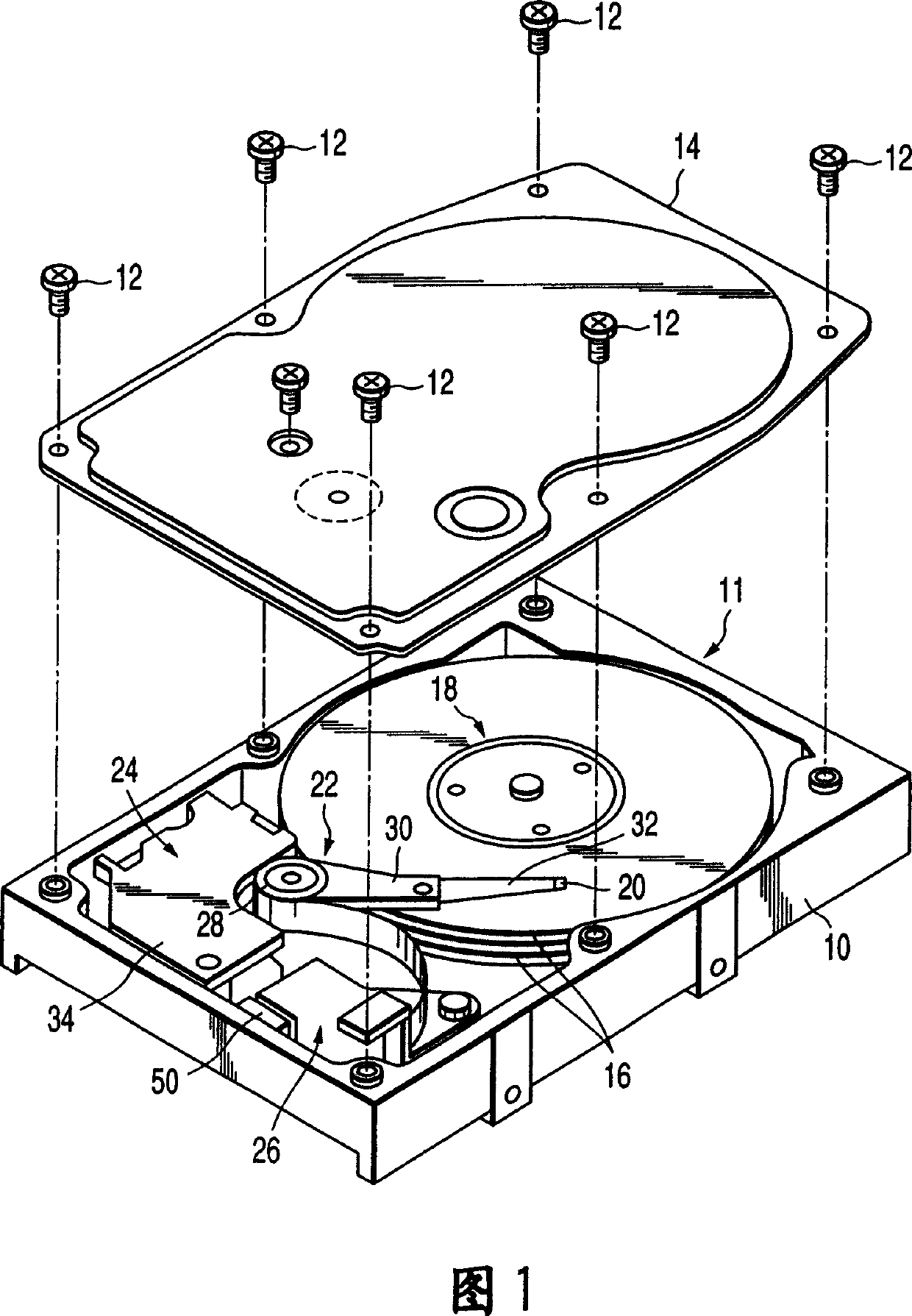

[0019] First, an example of an HDD to be checked will be described. As shown in FIG. 1 , the HDD includes a casing 11 of a substantially airtight structure, which includes a casing main body 10 and a top cover 14 . The housing body 10 is in the shape of a rectangular box with an open top, and the top cover 14 is screwed onto the housing body 10 with several screws 12 to close the open top of the housing body 10 .

[0020] Arranged in the case main body 10 are, for example, two magnetic disks 16 each serving as a magnetic recording medium; a spindle motor 18 for supporting and rotating these magnetic disks 16; Reading / writing of information; Carriage assembly 22, it supports these magnetic heads 20; Voice coil motor (VCM) 24, in order to rotate and position carriage assembly 22; And board assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com