Spring contact

A spring contact and compression spring technology, applied in the direction of clamping/spring connection, contact parts, etc., can solve the problems of large side pressure, height reduction and miniaturization of the conductive plug 101, and many factors of side pressure dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

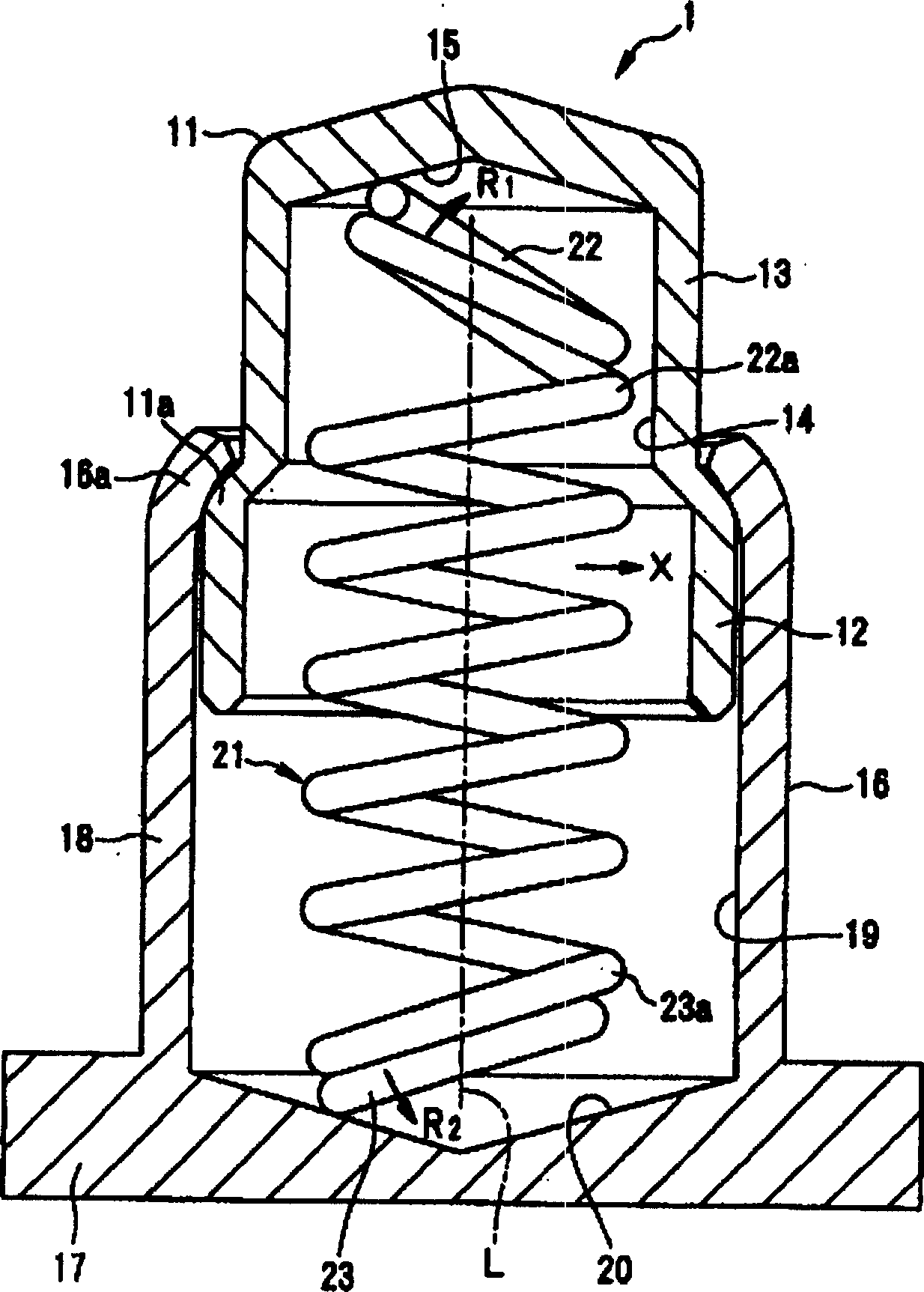

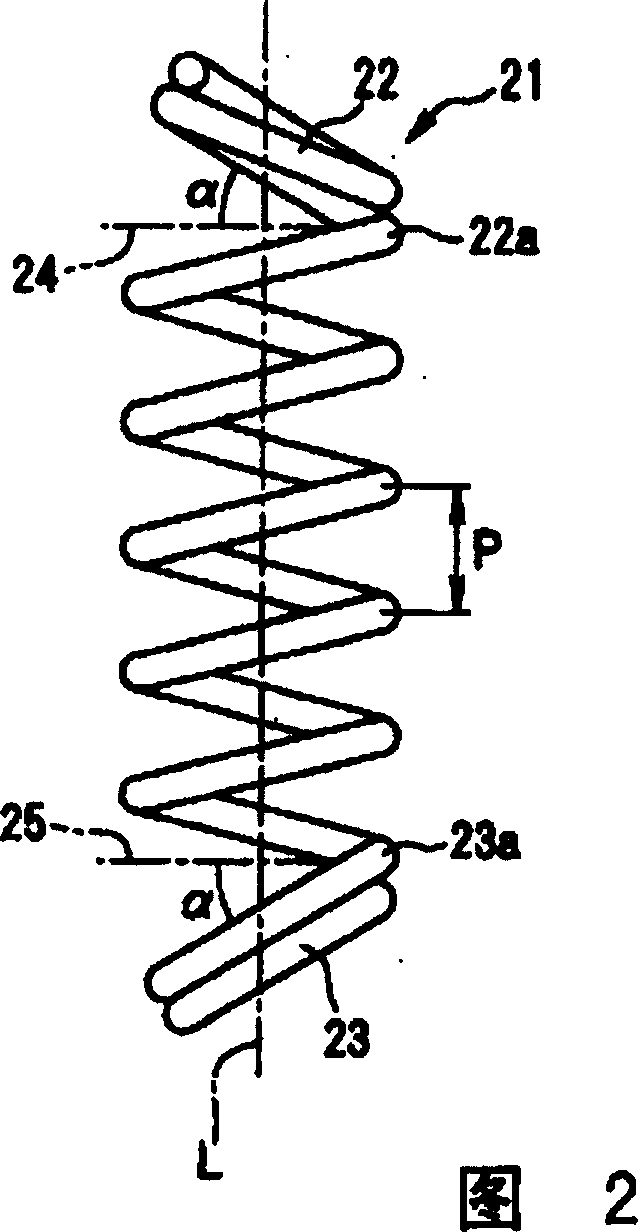

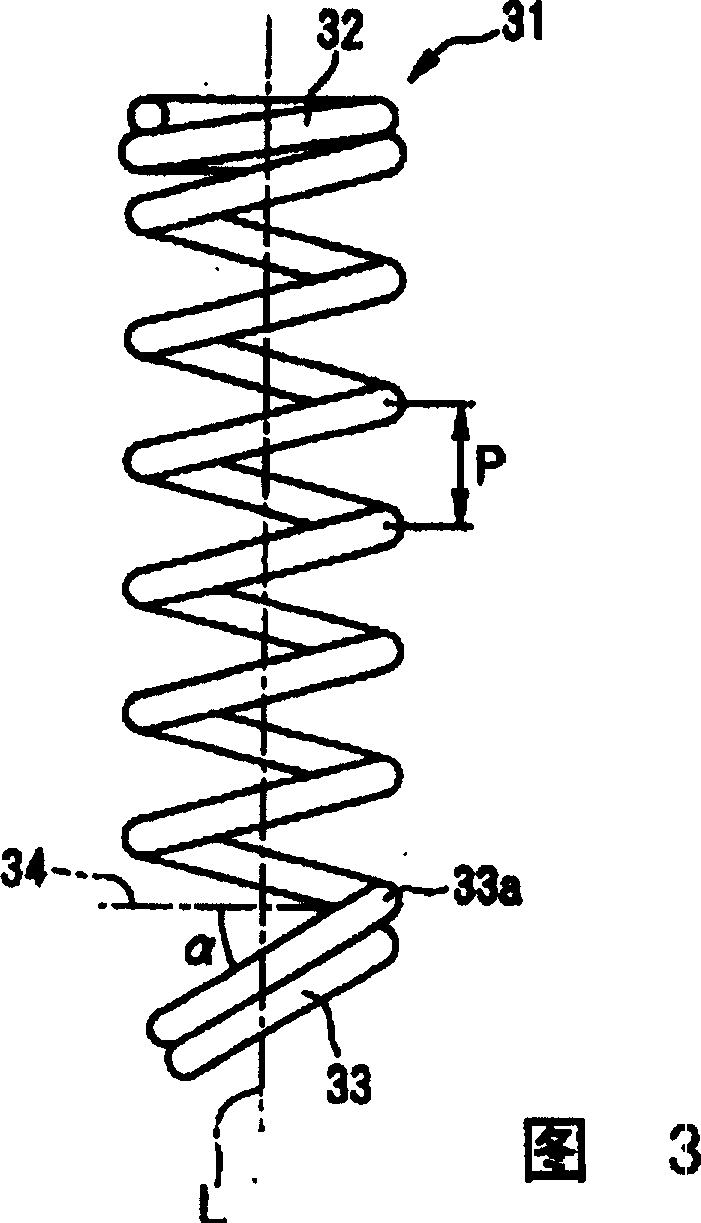

[0019] Embodiments of the present invention will be described below with reference to the accompanying drawings. figure 1 is a cross-sectional view of an embodiment of the spring contact of the present invention, but figure 1 The compression spring is not cut apart. Figure 2 is figure 1 Front view of the free state of the compression spring used in the spring contact shown.

[0020] figure 1 The shown spring contact 1 has a conductive plug 11 and a conductive tube 16, the conductive plug 11 is in contact with the built-in battery or antenna of the portable phone (not shown in the figure), the conductive tube 16 can freely slide to accommodate the conductive plug 11, and soldering onto the substrate (not shown in the figure). A compression spring 21 that presses the conductive plug 11 in a protruding direction is disposed inside the conductive tube 16 .

[0021] Here, the conductive tube 16 is composed of a soldering portion 17 and a cylindrical portion 18, and is made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com