Preparation method of nano apatite crystal composite tissue engineering support material

A scaffold material and composite tissue technology, which is applied in prostheses, pharmaceutical devices, medical science, etc., can solve problems such as weak interface binding force, composite interface damage, and loss of mechanical strength of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

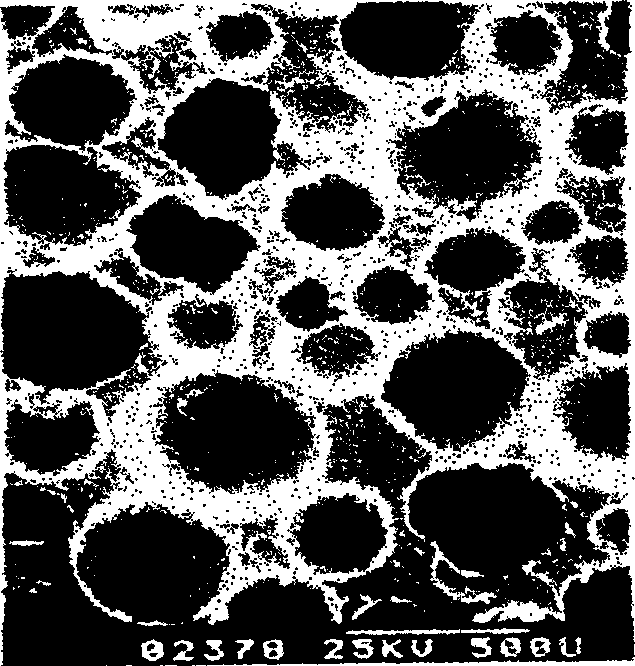

[0023] Preparation of nanoapatite crystals / polyamide 66 composites:

[0024] 164 grams of analytically pure calcium nitrate and 98.4 grams of sodium phosphate were added to a 3000ml three-necked bottle with water separator, stirring device and condensing device, and then 1500ml of N, N-dimethylacetamide (DMAC) was added. The temperature was gradually increased to 140° C., 55 g of polyamide 66 (molecular weight 23,000, supplied by Asahi Chemical Industry Co.) was added, and kept at 140° C. for 4 hours. Until the polyamide 66 is completely dissolved, cool to room temperature, slowly drop the mixture into a stainless steel pot filled with deionized water under constant stirring, heat to gradually increase the temperature of the mixture to 70°C, keep it warm for 2 hours, and then Cool to room temperature and age for 24 hours. Wash the product 3 times with deionized water, pour it into a beaker, raise the temperature to 95°C-100°C, and keep it warm for 3 hours; carry out hydrother...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com