Fuel injection valve

A technology for fuel injection valves and internal combustion engines, applied in fuel injection devices, special fuel injection devices, charging systems, etc., can solve problems such as enlarging sealing problems, and achieve the effect of reliable sealing and simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

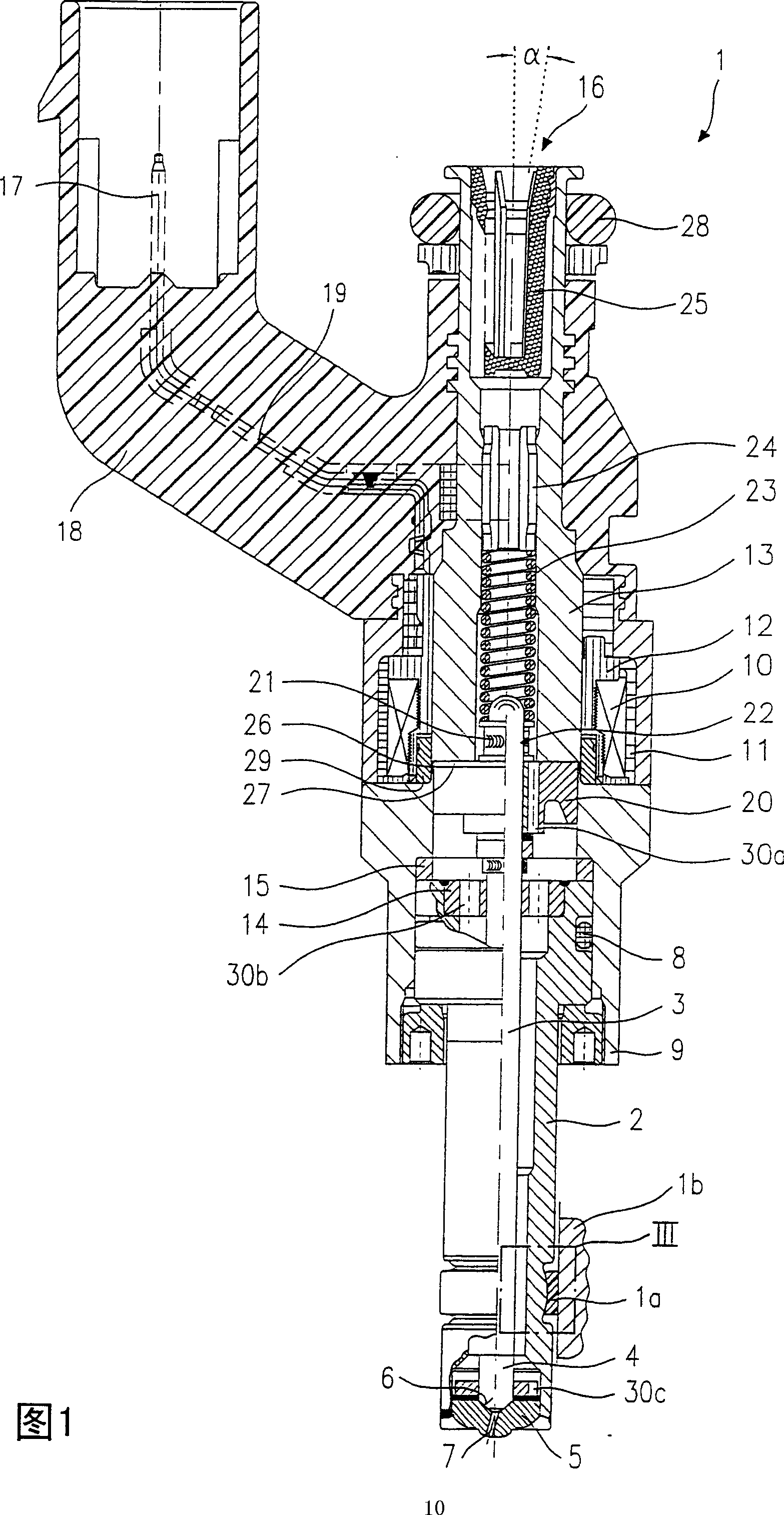

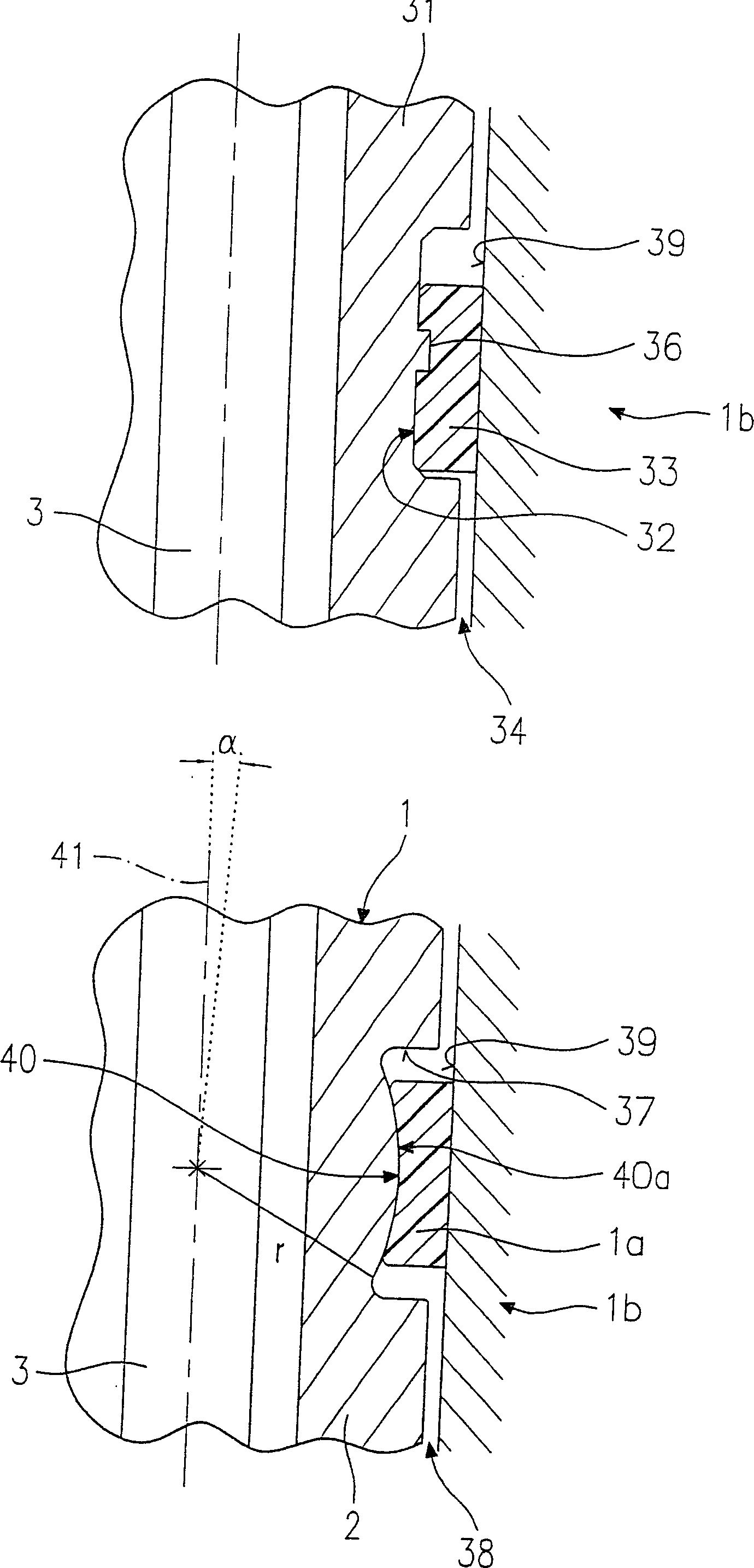

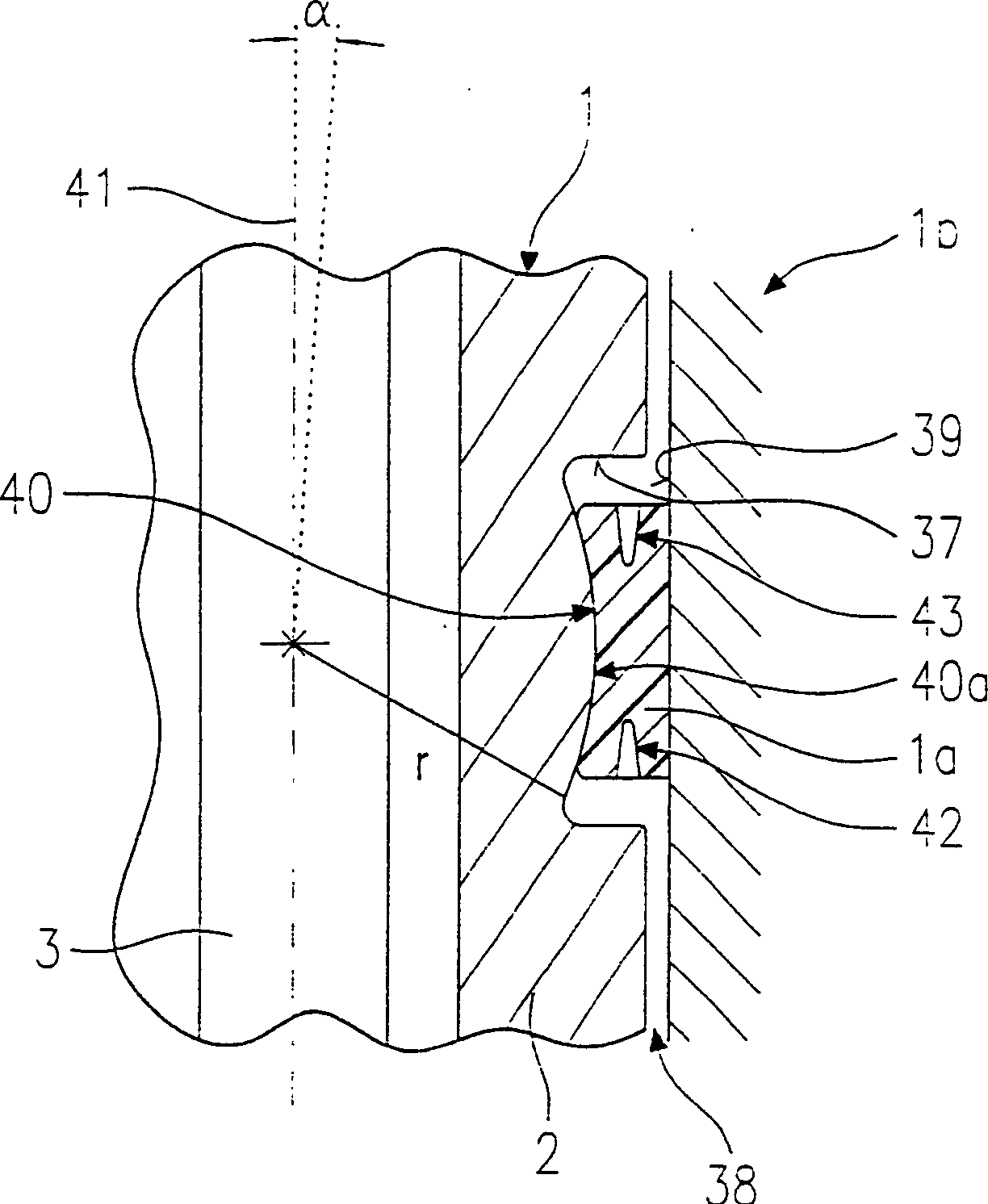

[0021] The fuel injection valve 1 according to the invention shown in FIG. 1 with a sealing ring 1 a is designed in the form of a fuel injection valve for a fuel injection system for a mixture-compressing, forced-ignition internal combustion engine. The fuel injector 1 is accommodated in a receiving bore, not shown in detail here, of a cylinder head 1b. The cylinder head 1b is shown as a cutaway plane only in the region of the sealing ring 1a, since this region which is relevant for the invention is described in more detail in the following figures. The fuel injector 1 is particularly suitable for injecting fuel directly into a combustion chamber (not shown) of an internal combustion engine.

[0022] The fuel injection valve 1 is formed by a nozzle body 2 in which a valve needle 3 is guided. The valve needle 3 is operatively connected to a valve closing body 4 which cooperates with a valve seat surface 6 arranged on a valve seat body 5 to form a sealing seat. In this exempla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com