Rotational flow type water collection method

A swirl type and water eliminator technology, applied in water shower coolers, direct contact heat exchangers, heat exchange equipment, etc., can solve the problem of low water collection efficiency and achieve the effect of improving water collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

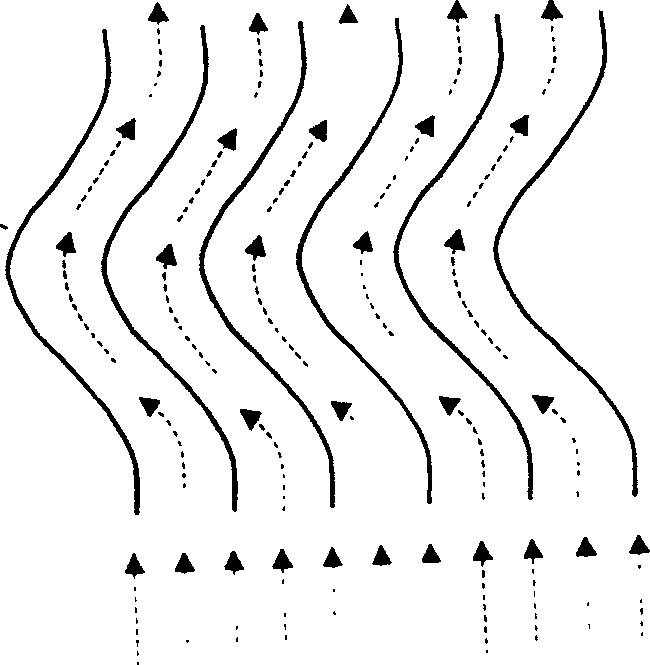

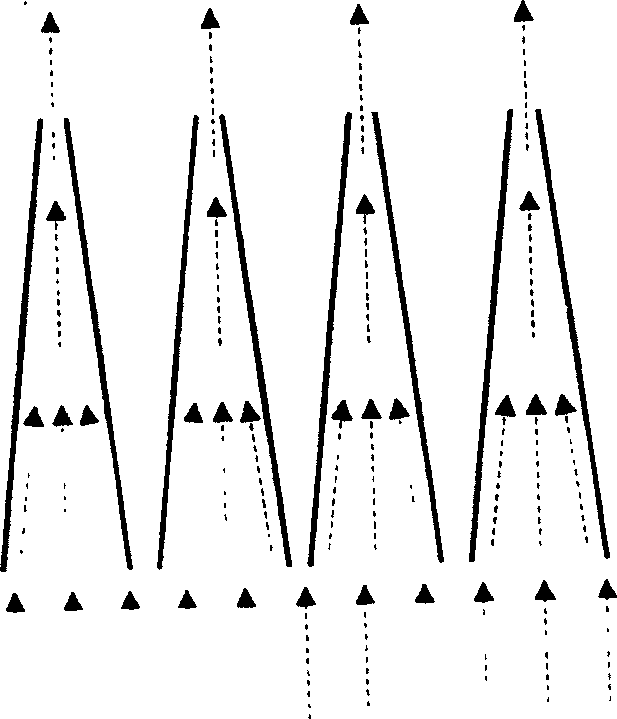

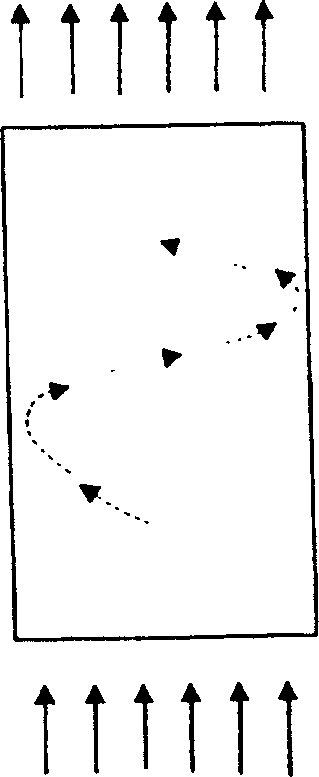

[0025] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] As can be seen from the figure, the method of the present invention uses a cylindrical water eliminator, which includes a cylindrical tube 2, and a pair of deflectors composed of a straight line side and an elliptical arc side placed crosswise to the straight line side are installed in the cylindrical tube 2. 3. The angle β between the guide plate 3 and the flow direction of the inlet of the moist air flow is 9.5°-79.3°, and its elliptical arc edge is in contact with the wall of the cylinder 2; the lower end of the cylinder 2 is equipped with an upper end of The circular lower end is a square base 4; the upper end of the cylindrical tube 2 is equipped with a fairing 1 with a certain thickness whose section is a grid; the side length of the square grid of the grid in the fairing 1 is 5 - 15%; the height of the base 4 is 1 / 10-7 / 10 of the diameter of the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com