Fuel injection system

A fuel injection system and fuel injection technology, applied in the direction of fuel injection devices, charging systems, combustion engines, etc., can solve the problem of large distance between fuel injection valve and spark plug, reduce temperature sudden change load, and improve ignition angle insensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

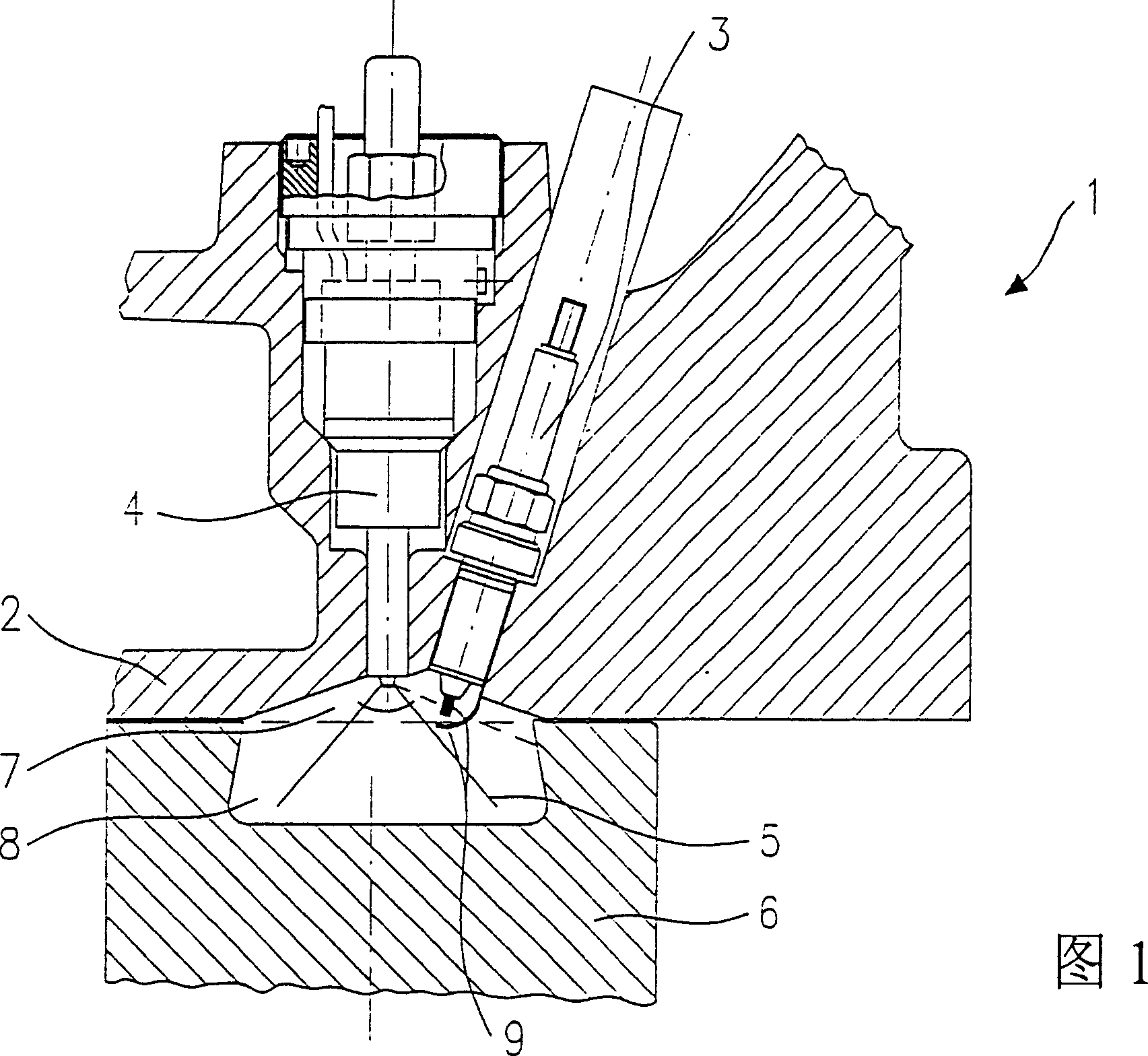

[0029] 1 shows a schematic partial section through a longitudinal section of a hybrid compression internal combustion engine 1 having a cylinder head 2 on which a spark plug 3 and fuel injection valves 4 are arranged in corresponding recesses. Since the structure of spark plug 3 and fuel injector 4 is basically known, no further description of these components will be given.

[0030] The fuel injection valve 4 injects fuel in the form of a cone-shaped injection jet 5 into a combustion chamber 7 defined by the cylinder head 2, the piston 6, and cylinder walls (not shown). The combustion chamber 7 is partially formed by a combustion chamber recess 8 formed on the piston 6 .

[0031] Fuel injector 4 and spark plug 3 are arranged relative to each other in such a way that spark plug 3 protrudes into combustion chamber 7 offset laterally relative to fuel injector 4 , spark plug electrode 9 being in the region of injected oil jet 5 .

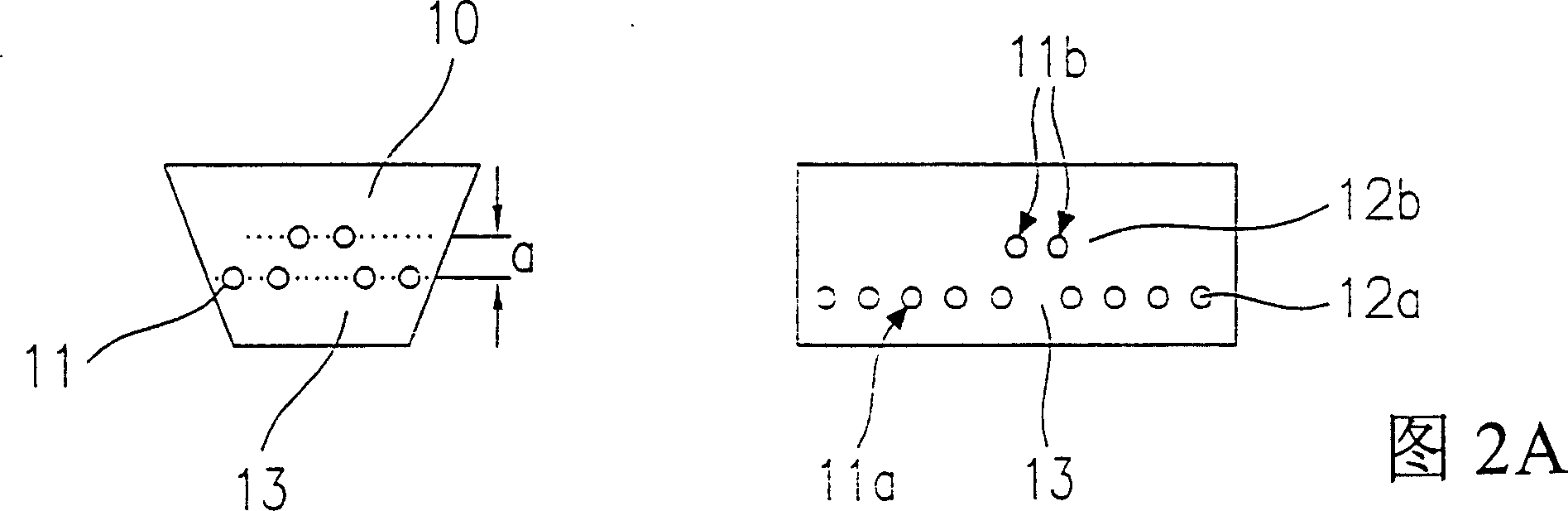

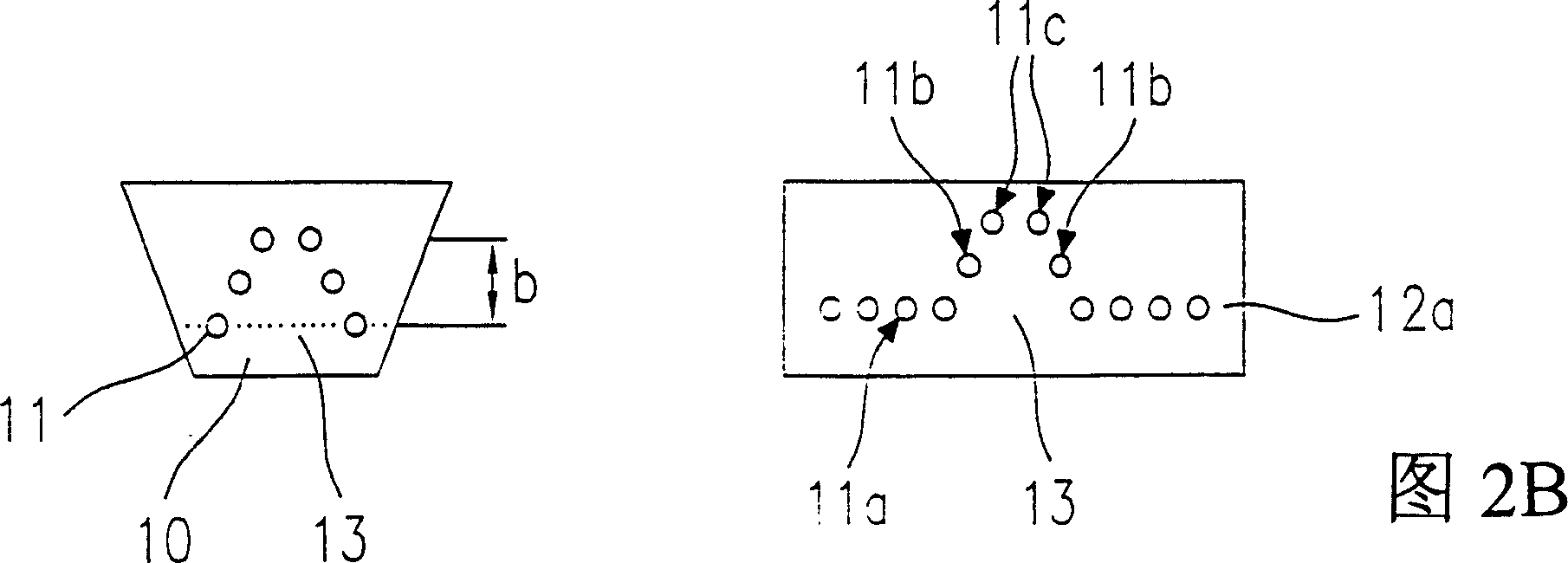

[0032] The shape of the injection jet 5 depends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com