Temperature compensating method of microwave oven with exhausting device

A technology of temperature compensation and exhaust fan, which is applied in the field of microwave ovens, can solve problems such as product performance dissatisfaction, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

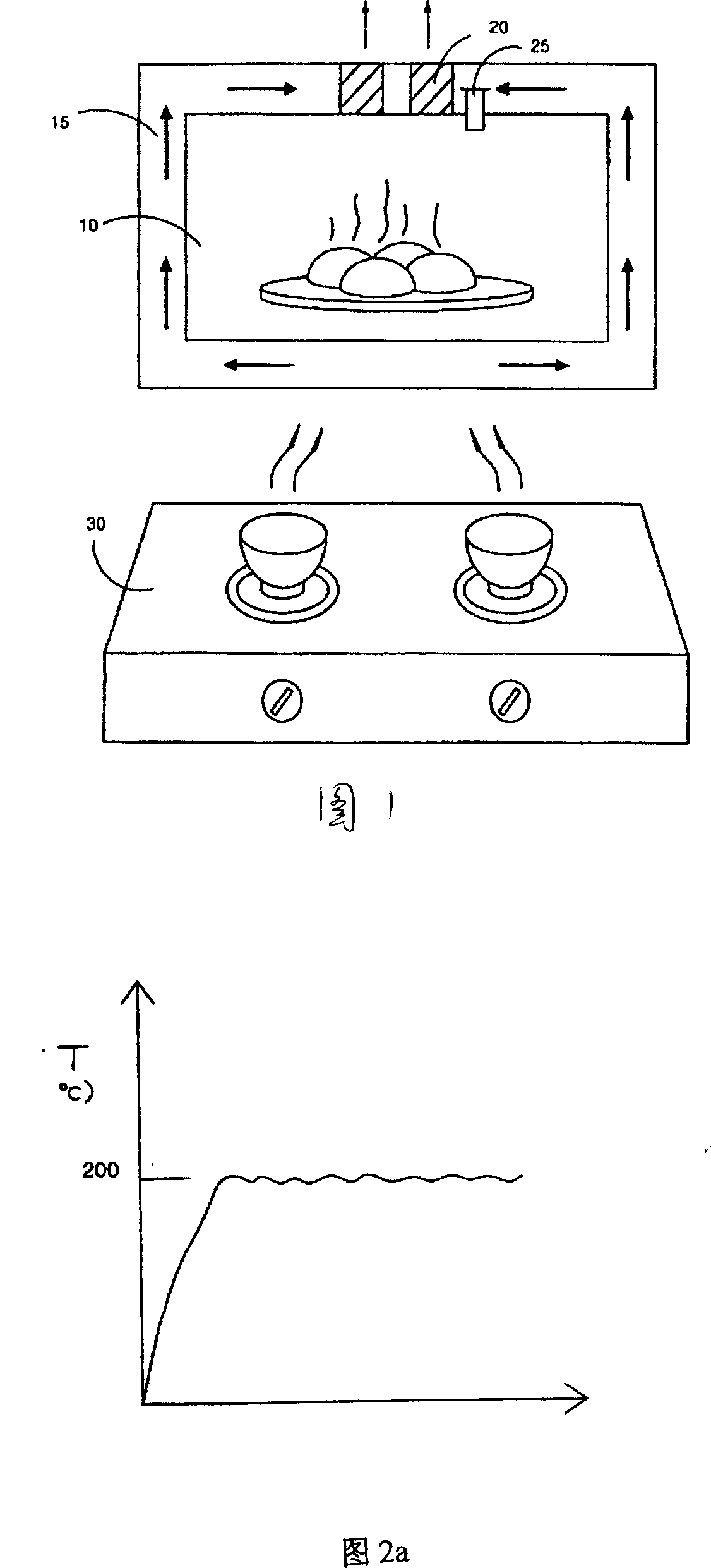

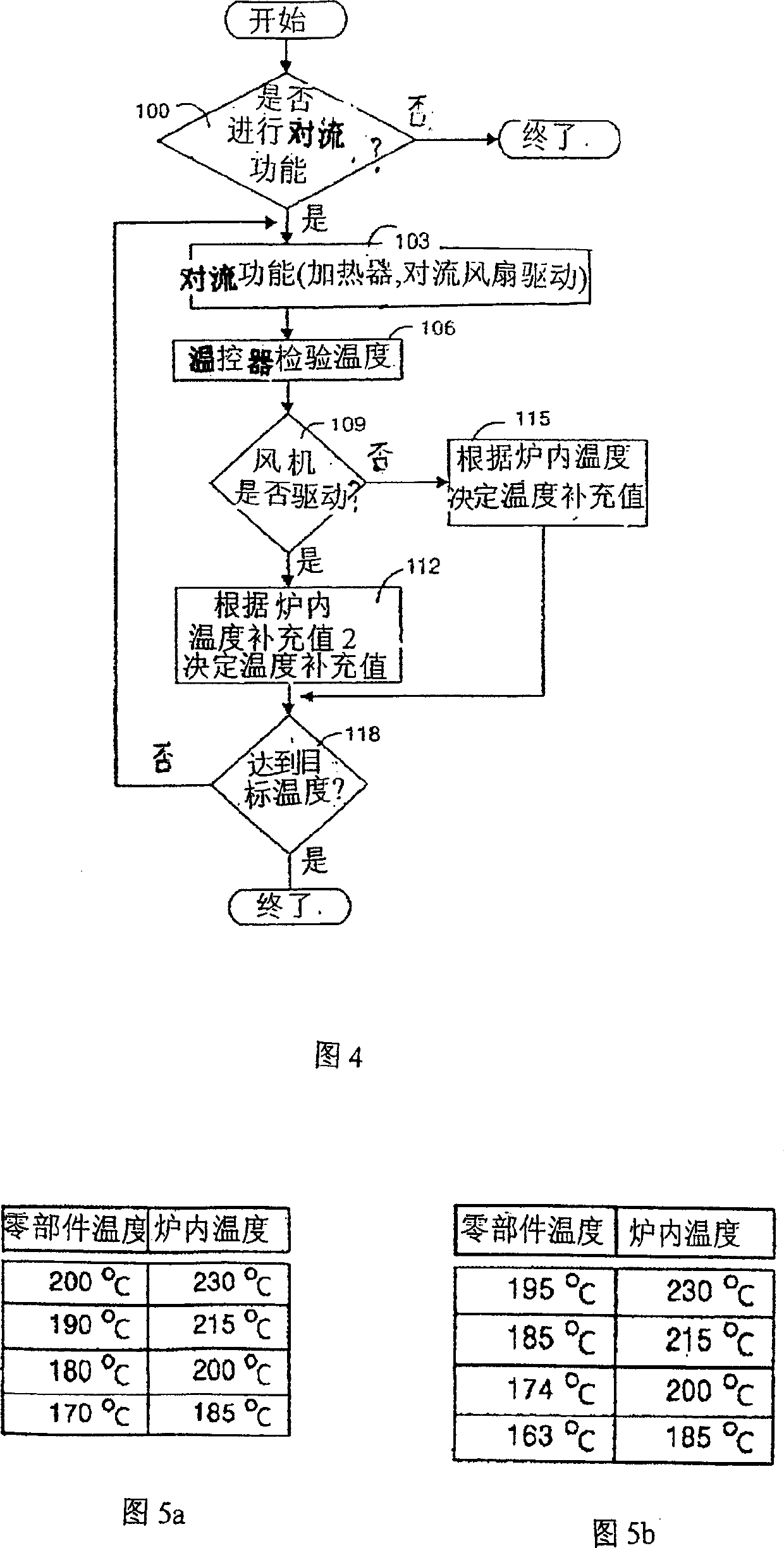

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments: FIG. 3 is a structural diagram of the temperature control structure of a microwave oven with an exhaust fan in the present invention, and the mechanical structure is described with reference to FIG. 1 .

[0031] As shown in FIG. 1 , it includes a thermo-control tube 25 inside the induction cooking chamber 10 , and the thermo-control tube 25 is installed on the top of the cooking chamber 10 or inside the side wall. The internal temperature of the cooking chamber detected by the thermal tube 25 is applied to the control part 50 through the thermal tube detection part 55 .

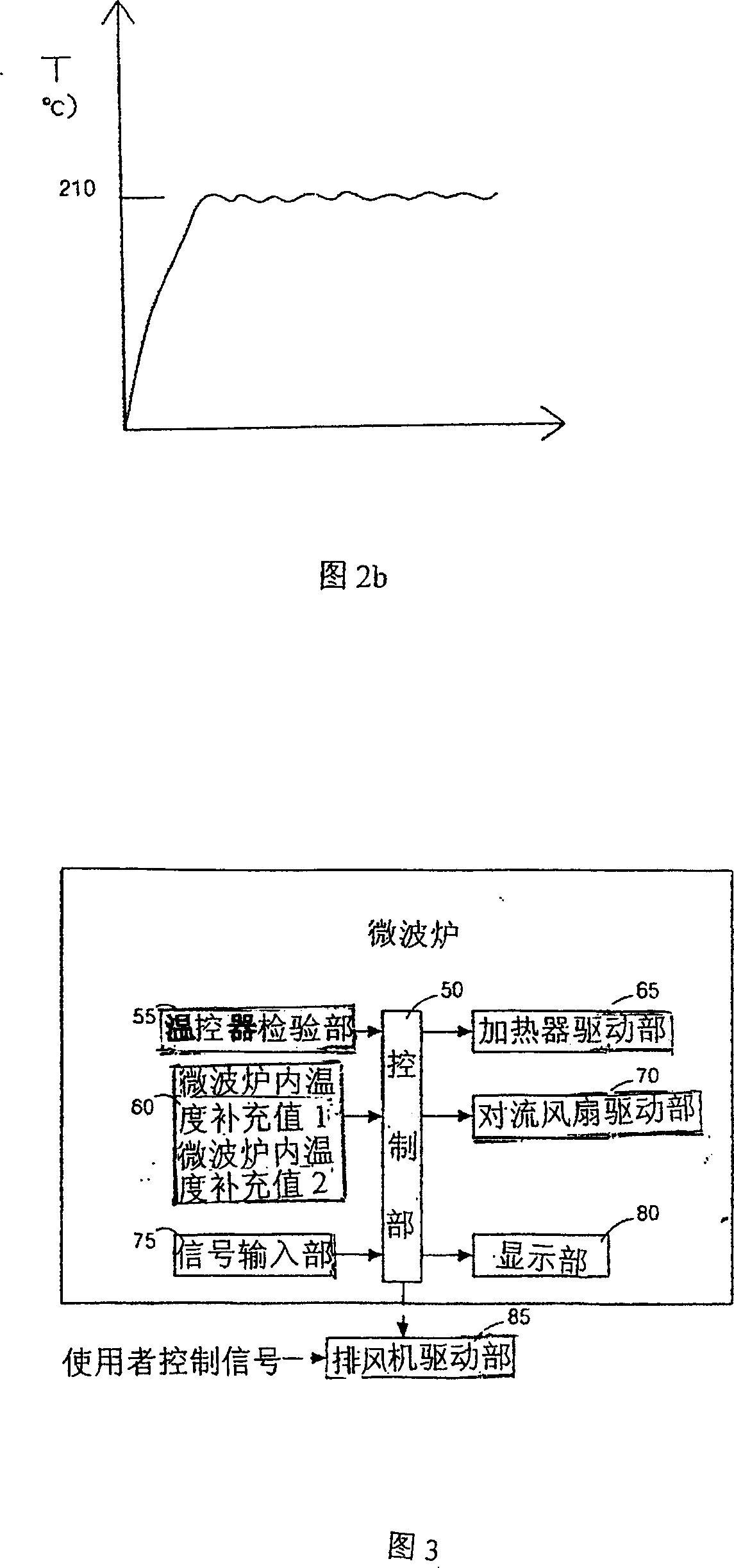

[0032] The control unit 50 utilizes the detection value of the thermal control tube detection unit 55 as a basis, and through temperature compensation, adjusts the cooking temperature. Especially the control unit 50 of the present invention, when using the direct heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com