Heating cooker

A cooker and heating chamber technology, applied in the direction of electric heating fuel, steam cooking utensils, lighting and heating equipment, etc., can solve the problems of overheating, incorrect heating control, and difficulty in correct temperature measurement, etc., to achieve expansion The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

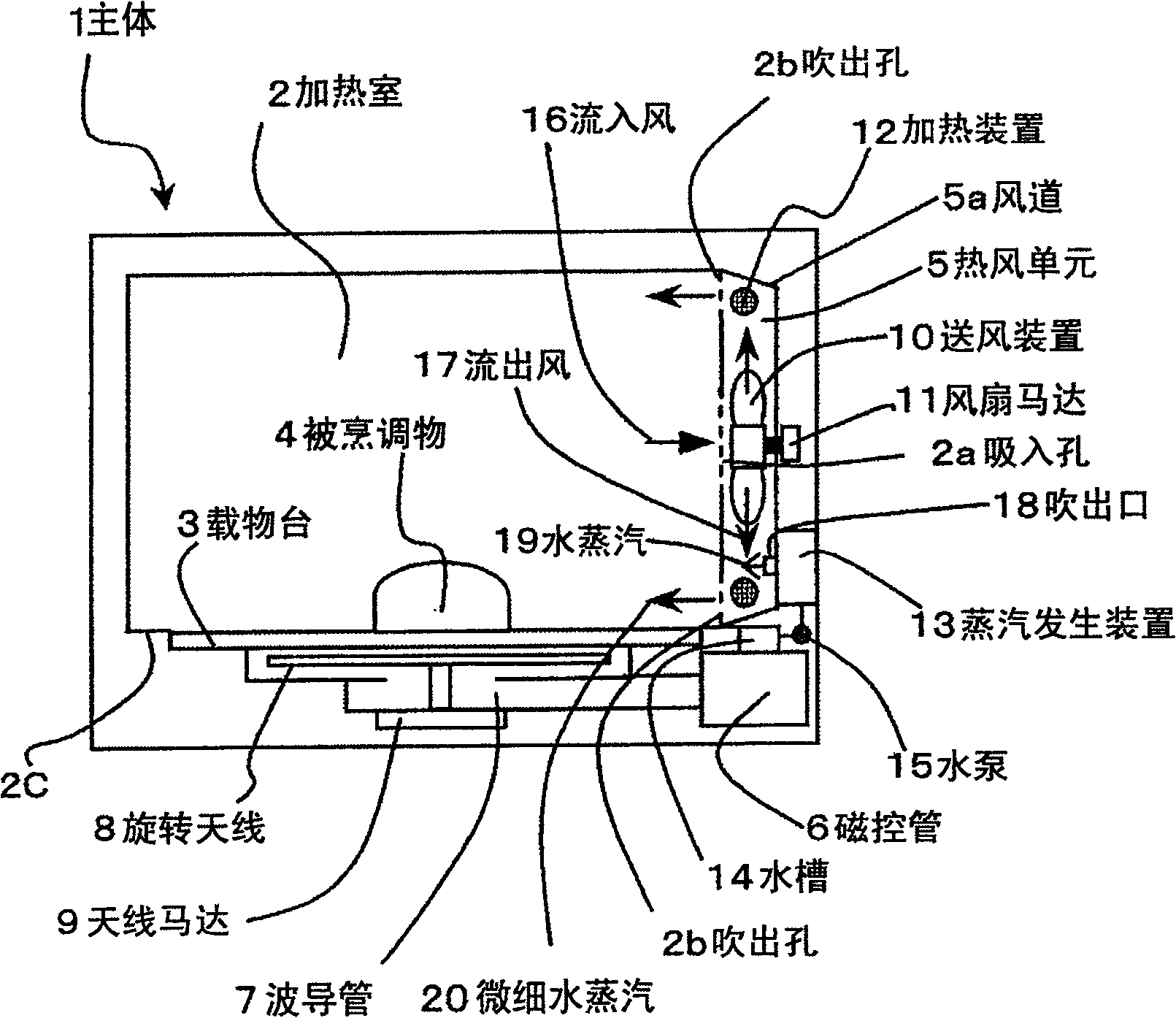

Method used

Image

Examples

Embodiment 2

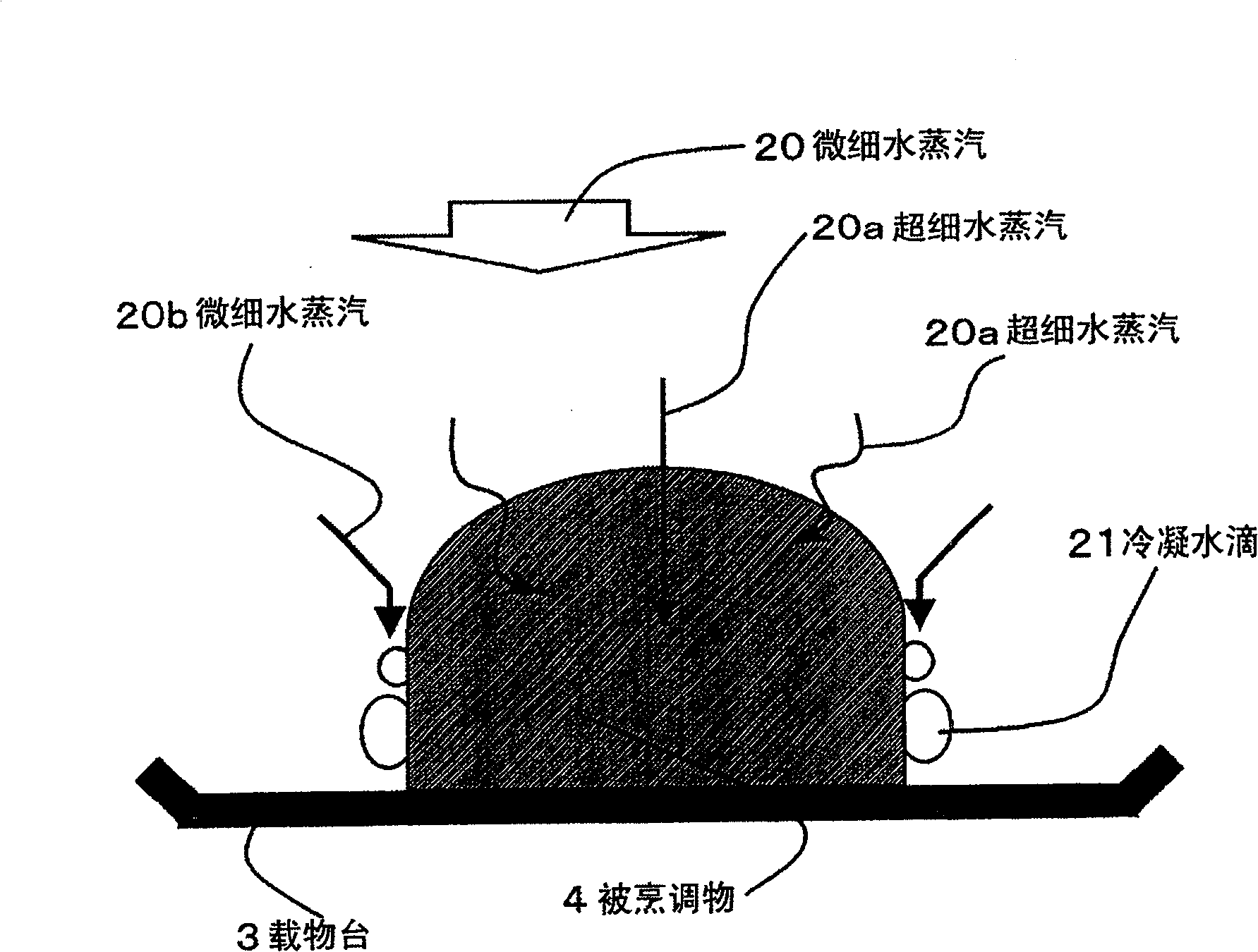

[0080] Figure 4 is another embodiment of the present invention, although with figure 1 The same is a non-rotary electronic microwave oven, but the stage 3 arranged on the bottom surface of the heating chamber 2 is separated from the heating chamber 2, and can be freely assembled and disassembled with the heating chamber 2. 4. The mass detection device 22 of weight is the biggest difference.

[0081] According to this structure, it is characterized in that the weight of the object to be cooked 4 on the stage 3 can be detected by the quality detection device 22, and the water vapor quantity 19 supplied from the steam generating device 13 is controlled by the control device 27 according to the detected value, And an appropriate amount of fine water vapor 20 corresponding to the cooking content of the object to be cooked 4 is supplied into the heating chamber 2 .

[0082] Figure 5 It is an example of the mass detection device 22, and the measurement principle is a capacitive ...

Embodiment 3

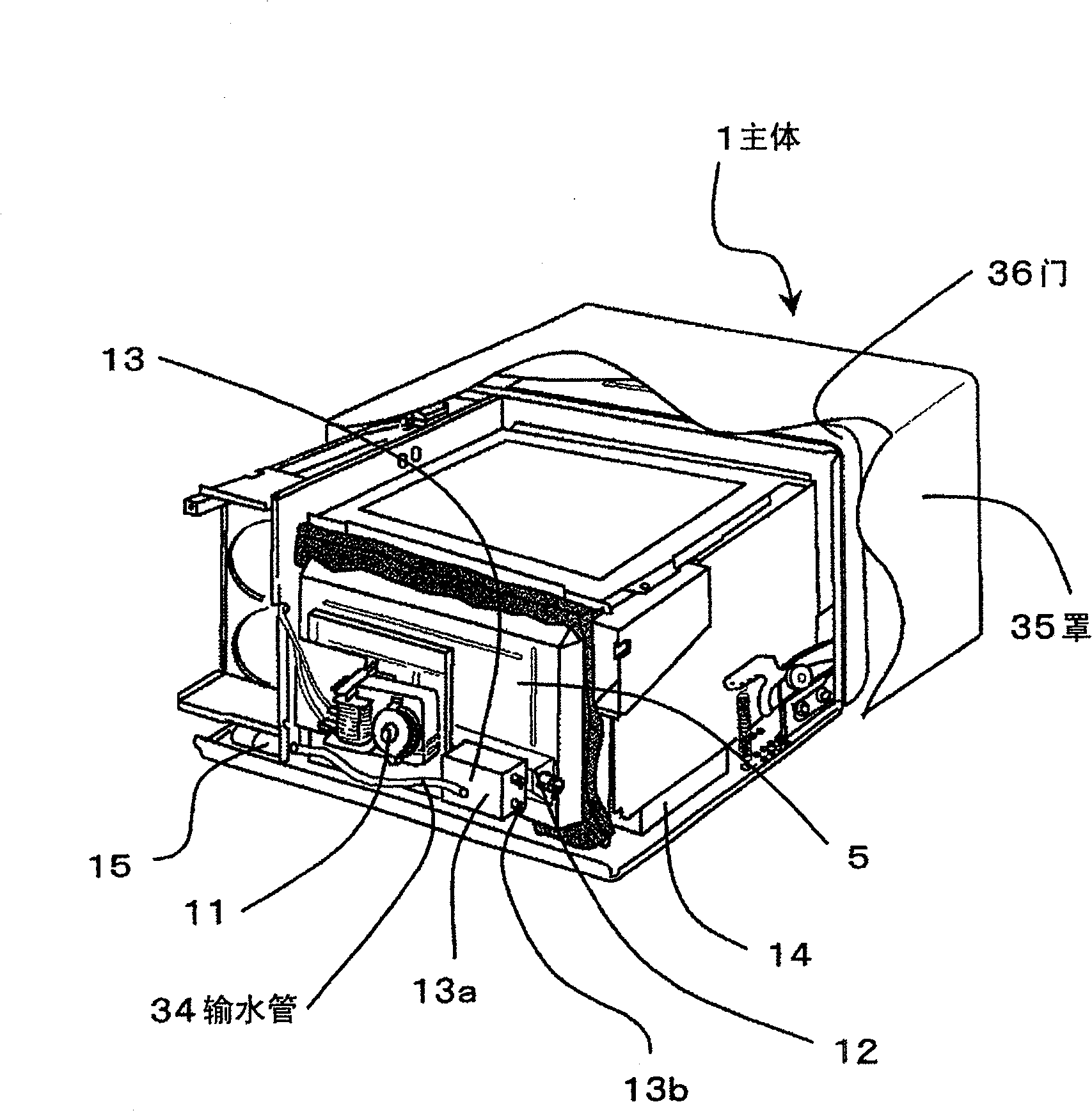

[0111] Figure 8 It is another embodiment of the present invention, which is different from the above-mentioned embodiment. It is a turntable electronic microwave oven in which the rotary stage 32 arranged in the center of the heating chamber 2 rotates. It is the same as the above-mentioned embodiment, and has a hot air unit 5 .

[0112] Hot air unit 5 and steam generating device 13 and figure 1 , Figure 4 Same, its structure is that the microwave sent from the magnetron 6 passes through the waveguide 7 and irradiates on the food to be cooked 4 from the side of the heating chamber 2 .

[0113] The rotary stage 32 is rotated by the stage motor 33 at its lower part, and a mass detection device 22 is arranged at its coaxial end, by which the mass detection device 22 can detect the objects loaded on the rotary stage 32. The weight of cooking object 4, its quality detection signal 23 is delivered to control device 27. The cooking method is the same as above Figure 7 The conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com