Patents

Literature

32results about How to "Effective blowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

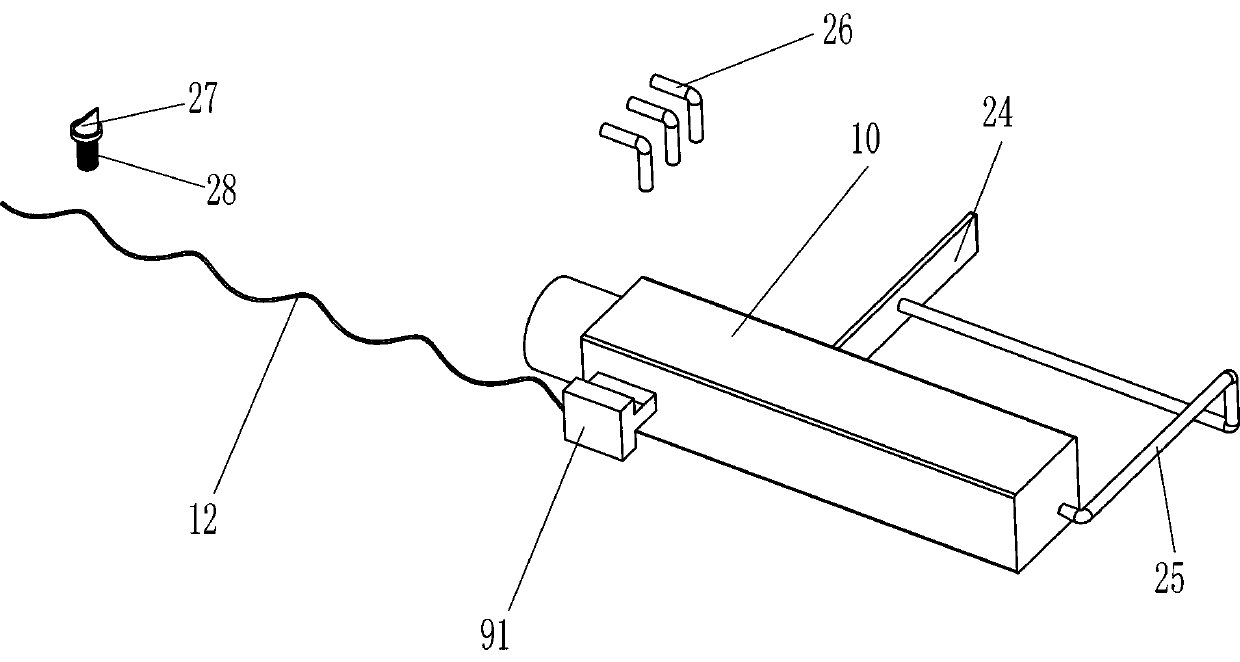

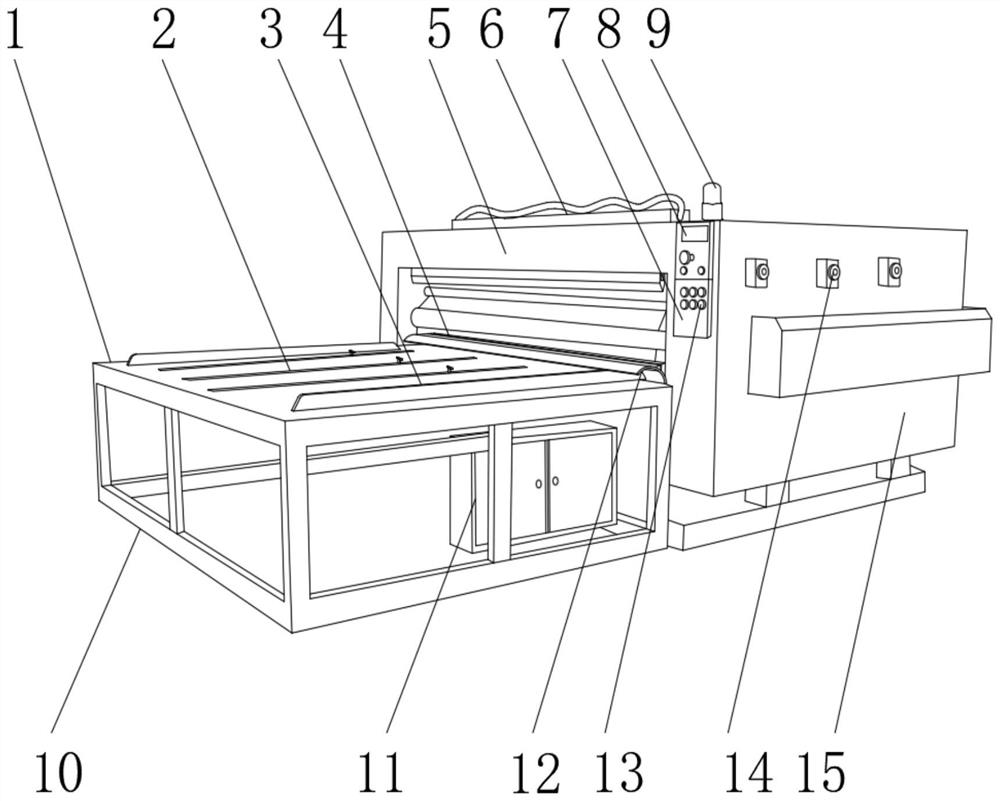

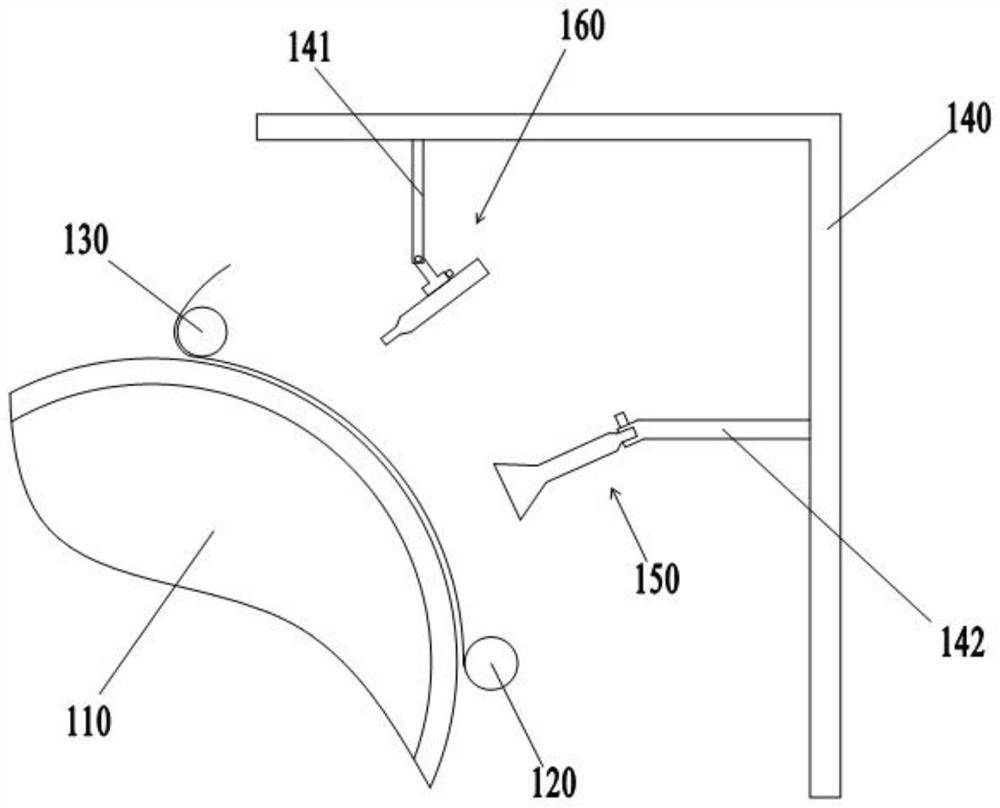

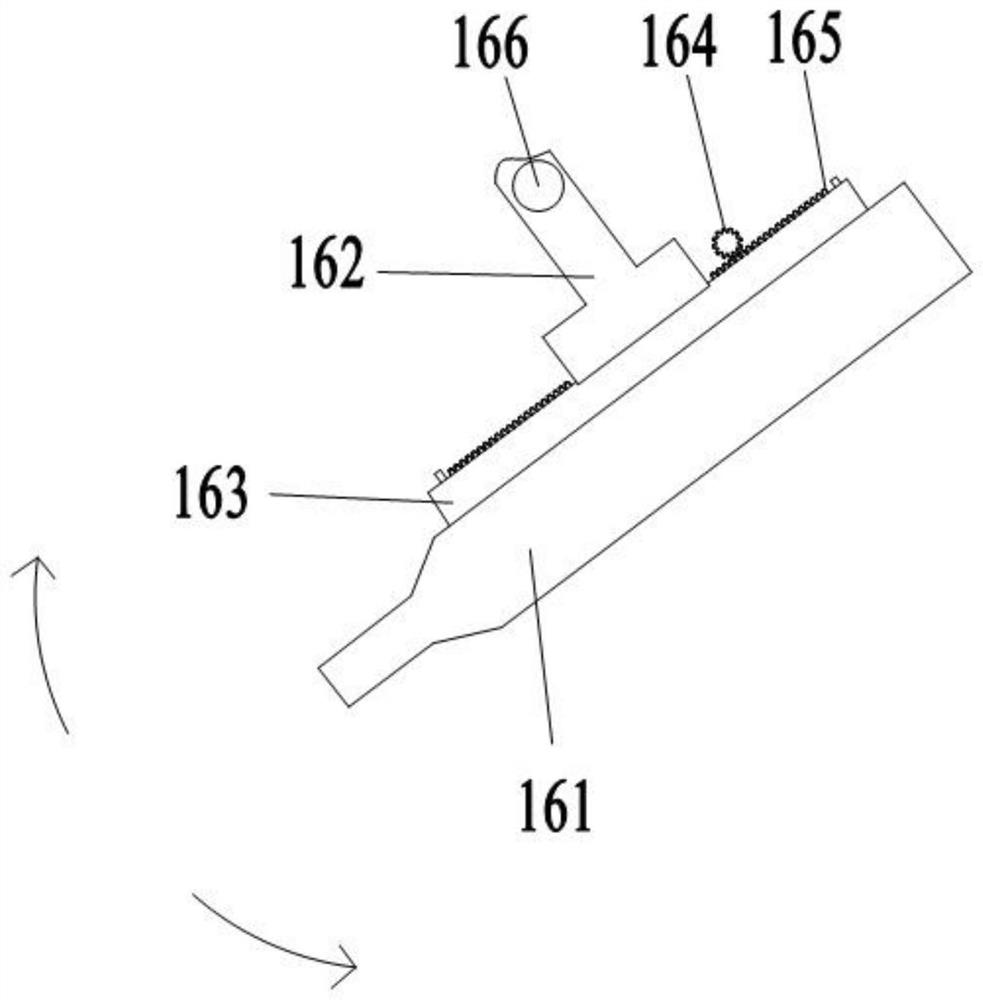

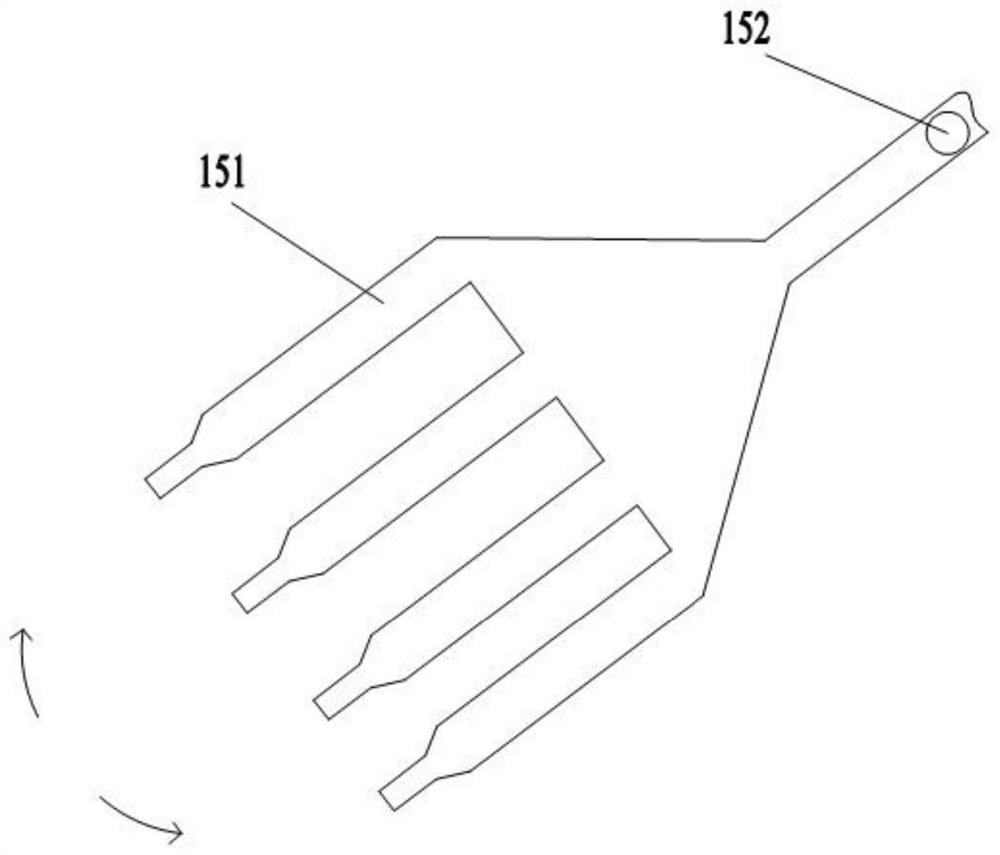

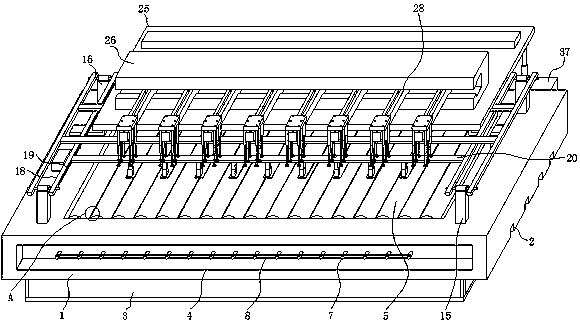

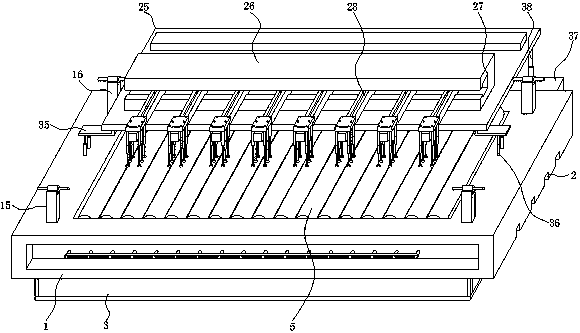

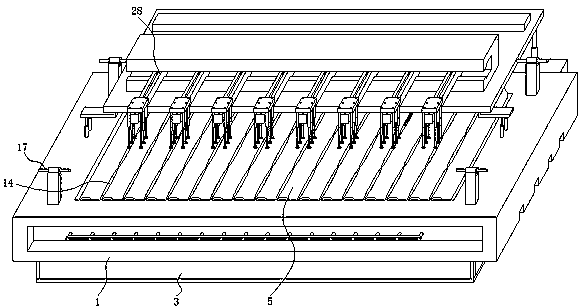

Surface dust removing device for liquid crystal glass sheet before powder spraying

InactiveCN110479720AEasy to cleanSimple structural designPretreated surfacesFlexible article cleaningEngineeringGlass sheet

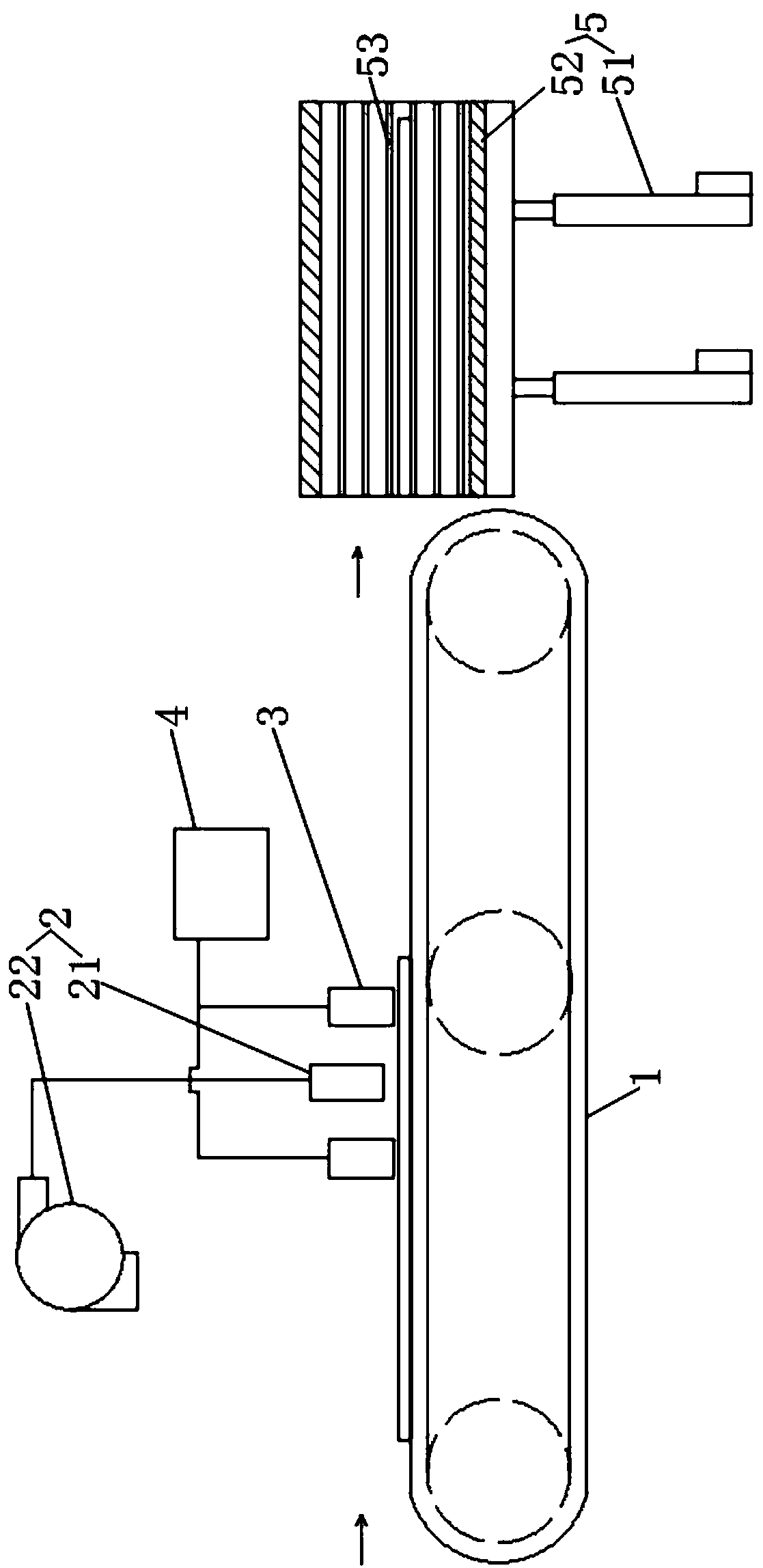

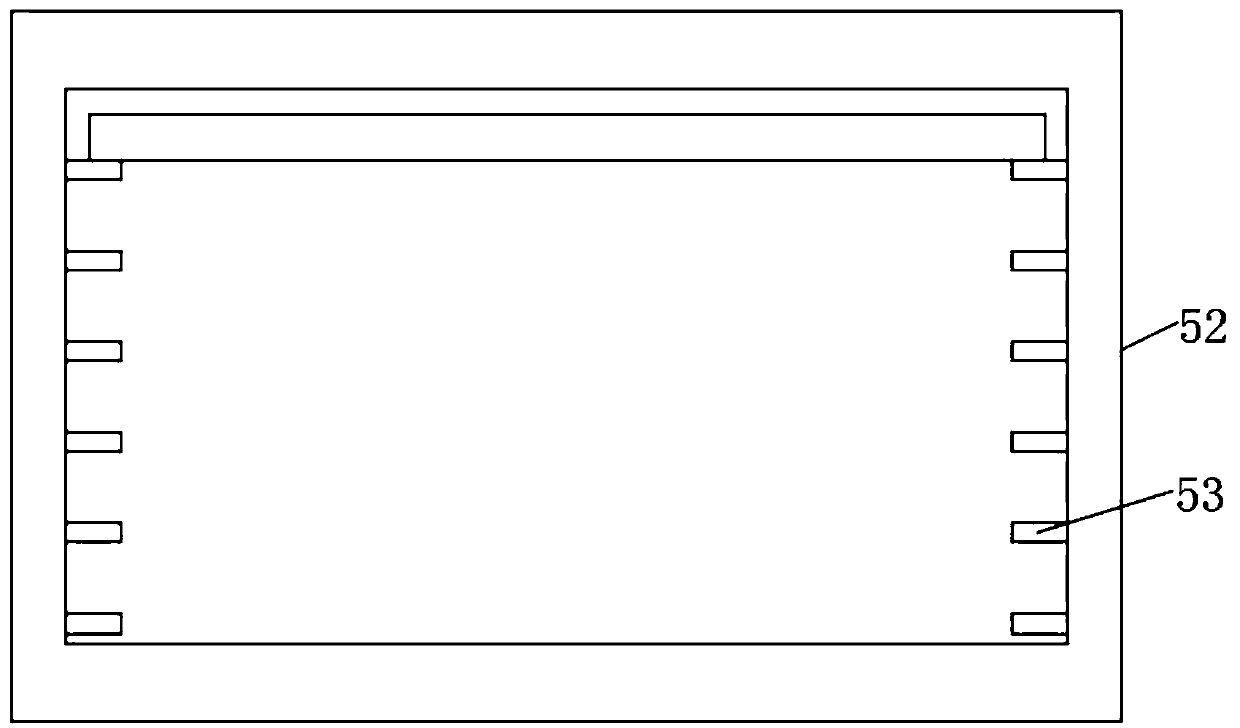

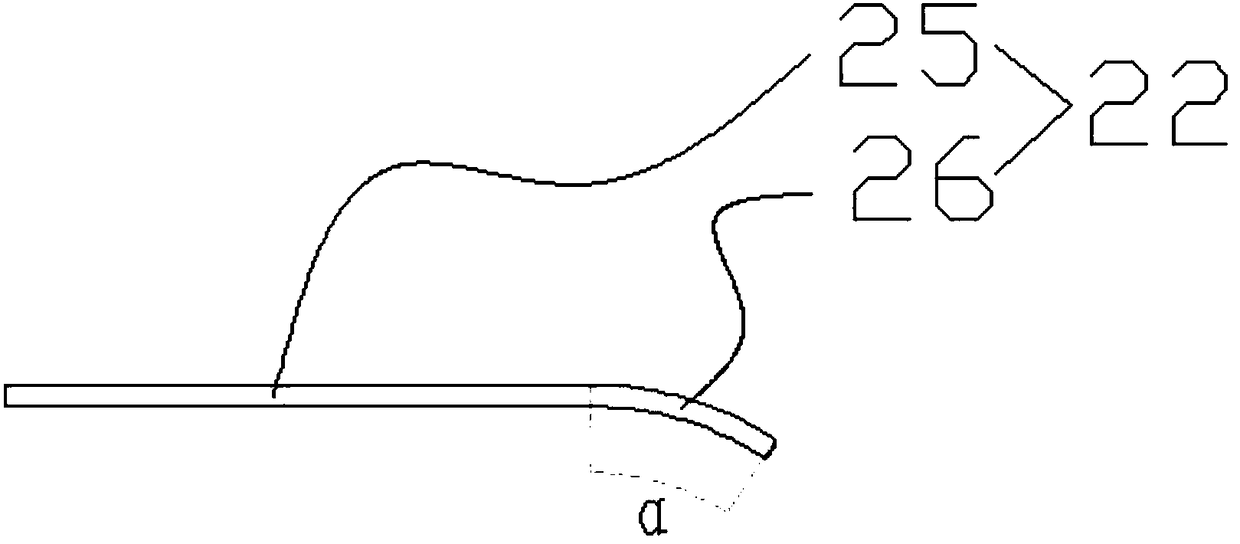

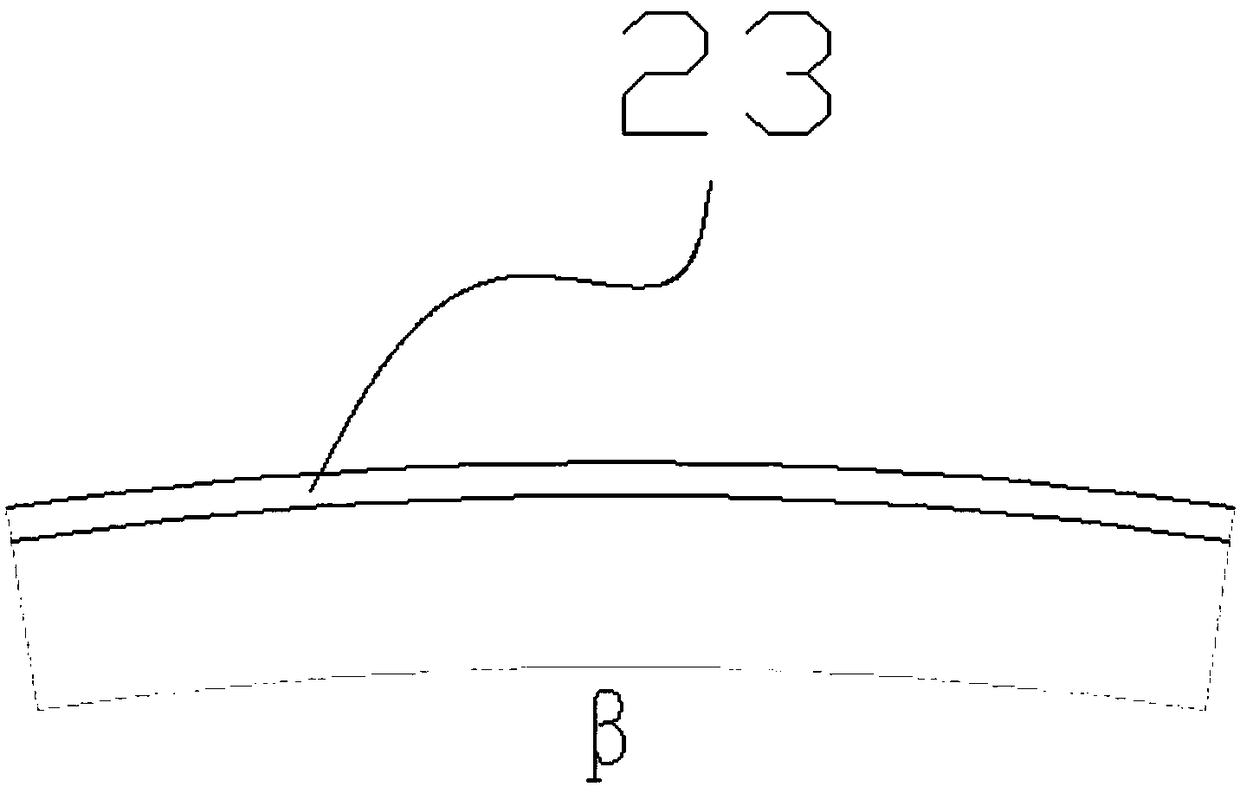

The invention relates to a liquid crystal glass sheet processing technology, in particular to a surface dust removing device for a liquid crystal glass sheet before powder spraying. The surface dust removing device for the liquid crystal glass sheet before powder spraying comprises a linear conveying device and a blowing dust removing device, wherein one end of the linear conveying device is a feeding end, and the other end of the linear conveying device is a discharging end; and the blowing dust removing device is arranged above the conveying surface of the linear conveying device and is usedfor blowing and removing dust on the surface of the liquid crystal glass sheet passing through the conveying surface of the linear conveying device, and the air outlet direction of the blowing dust removing device is inclined downwards towards the feeding end of the linear conveying device. The surface dust removing device has the advantages that the structure design is simple and ingenious, dustand impurities on the surface of the glass sheet can be effectively cleared in the liquid crystal glass sheet conveying process, and subsequent production is guaranteed to be well conducted.

Owner:HUBEI YOULIDI DISPLAY TECH CO LTD

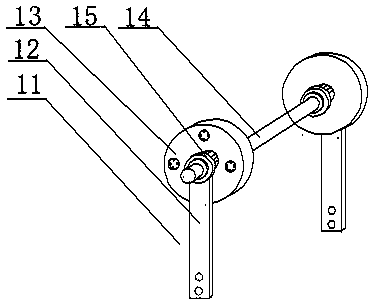

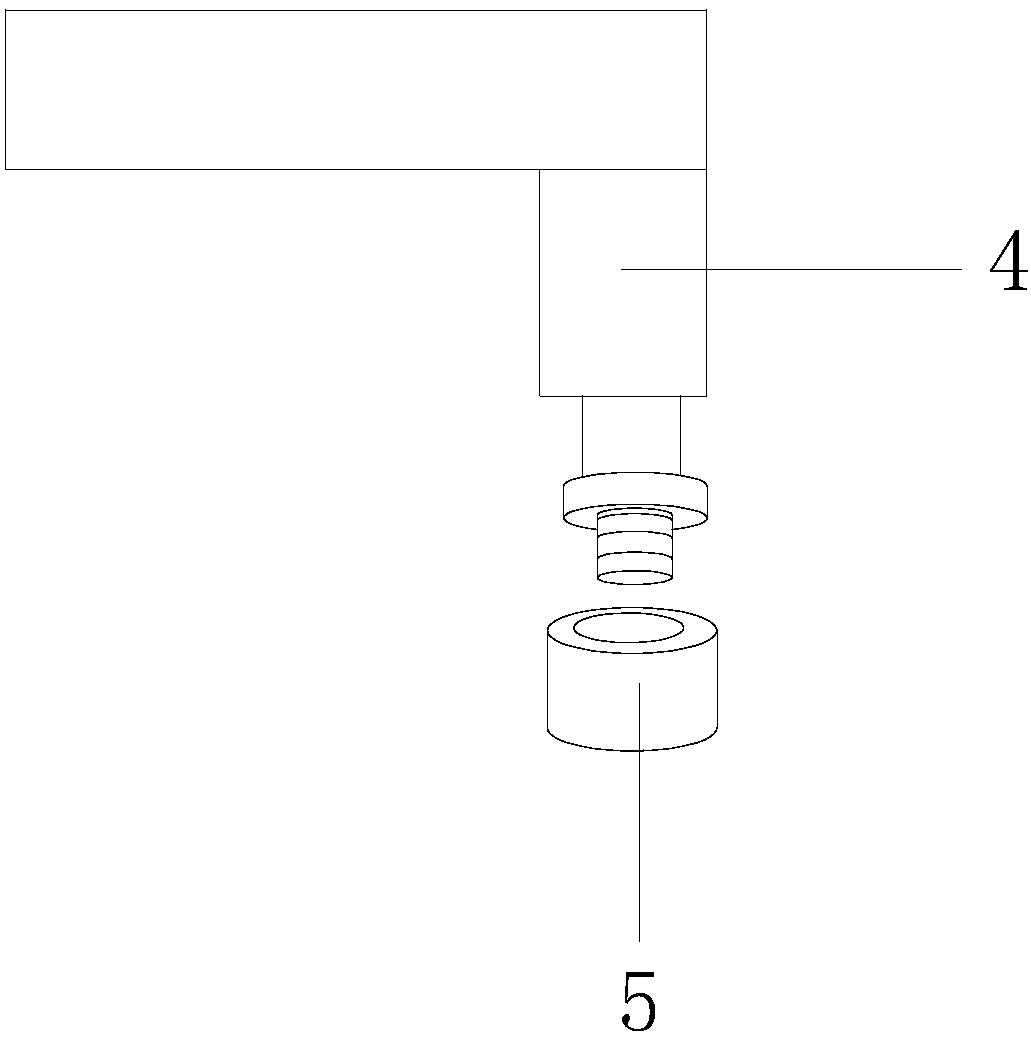

Automatic beating device for scraper production

PendingCN111251257AImprove work efficiencyReduce security risksPortable percussive toolsCleaning using gasesElectric machineryIndustrial engineering

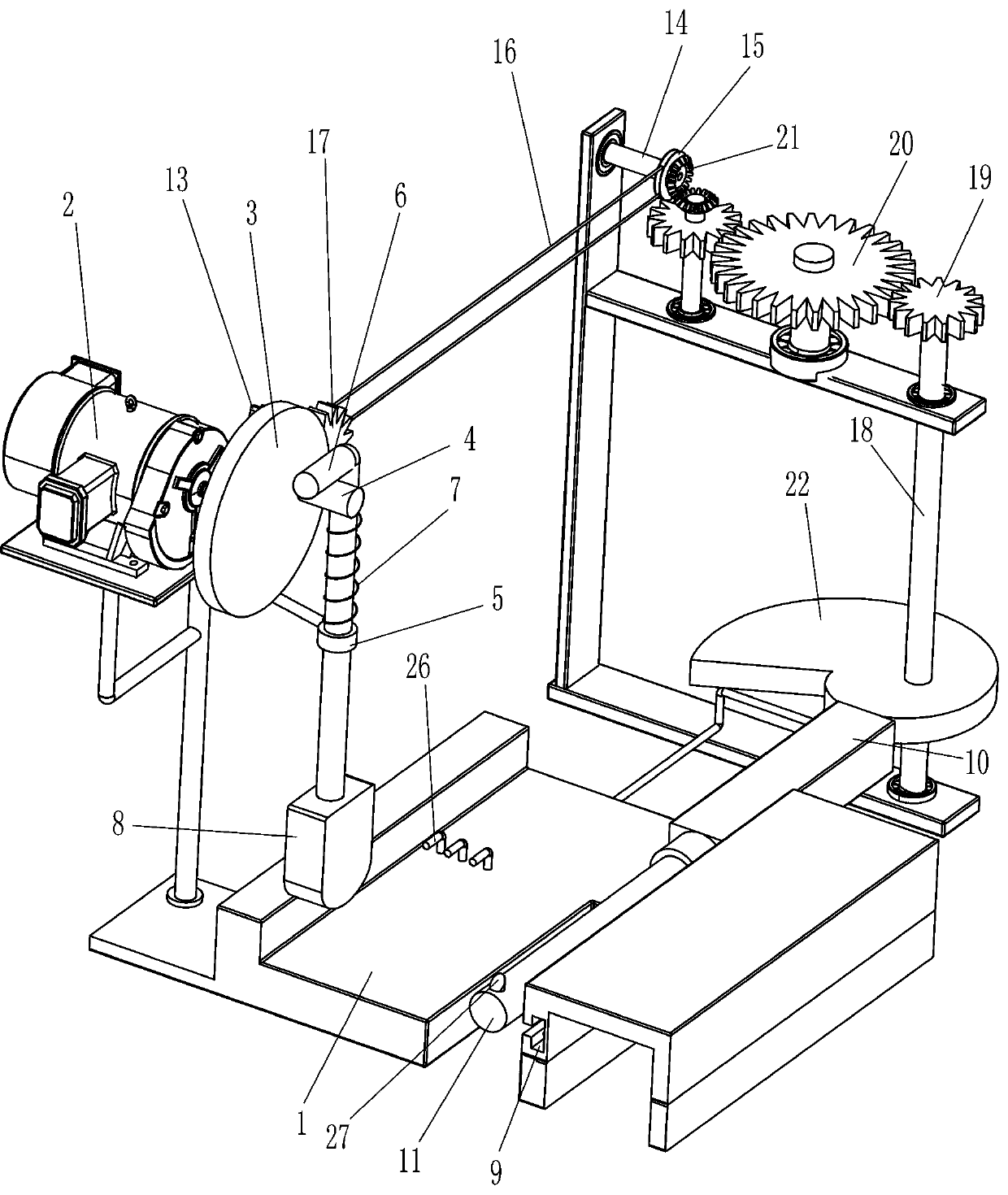

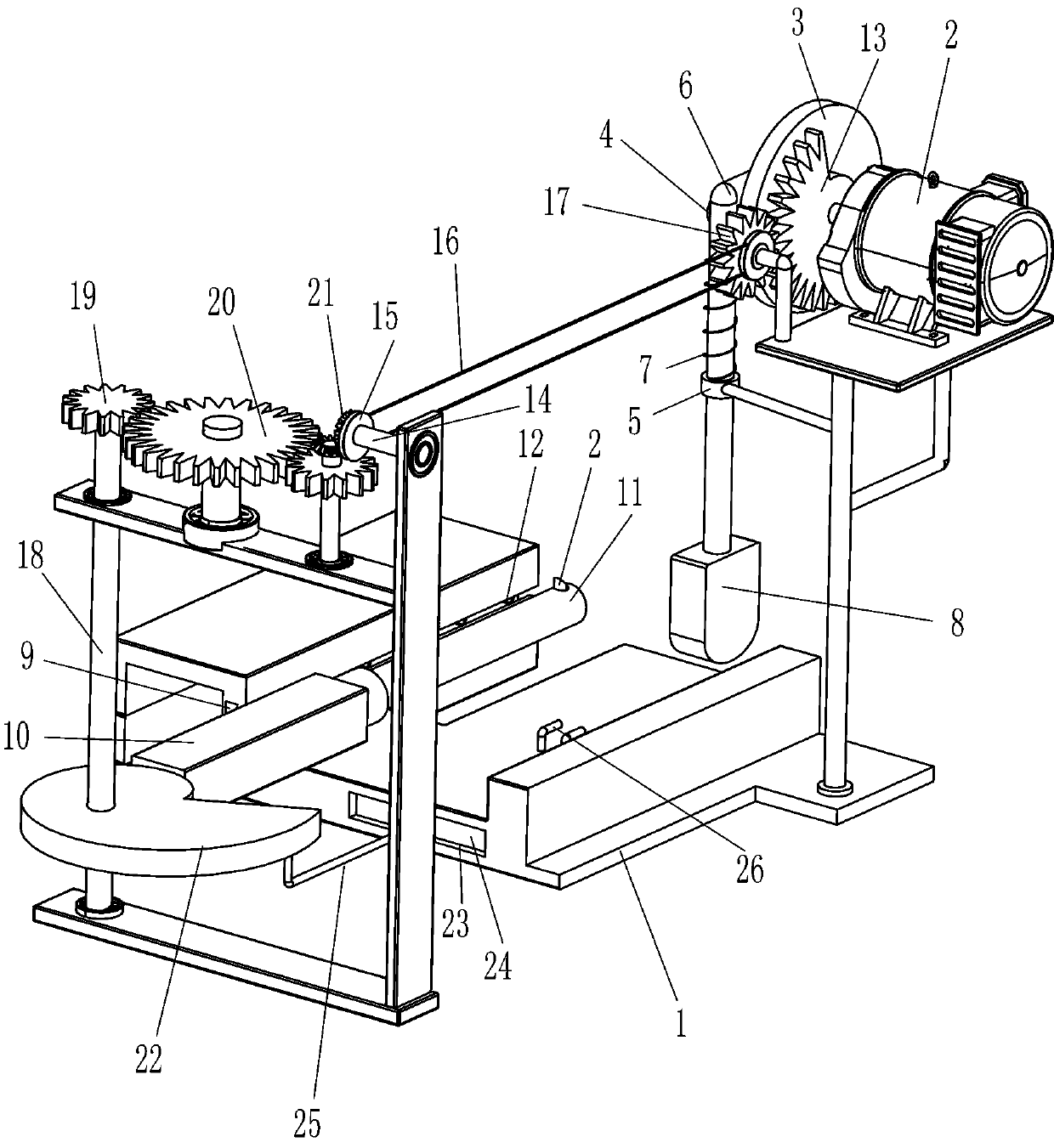

The invention relates to a beating device, in particular to an automatic beating device for scraper production. The technical aim of the automatic beating device for scraper production is that a scraper is automatically beaten and moved, thus the work efficiency is improved, and the safety risk is reduced. The automatic beating device for scraper production comprises a base, a hammering assembly,a placement assembly and the like; and the hammering assembly powered by a motor is arranged on the base, and the placement assembly for placing the scraper is arranged on the base. Through cooperation of a push rod and an L-shaped sliding rod, the scraper does not need to be manually hammered, and thus the work efficiency is improved; through cooperation of a sliding groove and a sliding block, the scraper can be constantly moved to enable a hammer to hammer different parts of the scraper, and thus the safety risk is reduced; and through cooperation of a sector gear and a first gear, the scraper does not need to be manually moved, and thus the automatic beating device is move convenient to use.

Owner:孙忠君

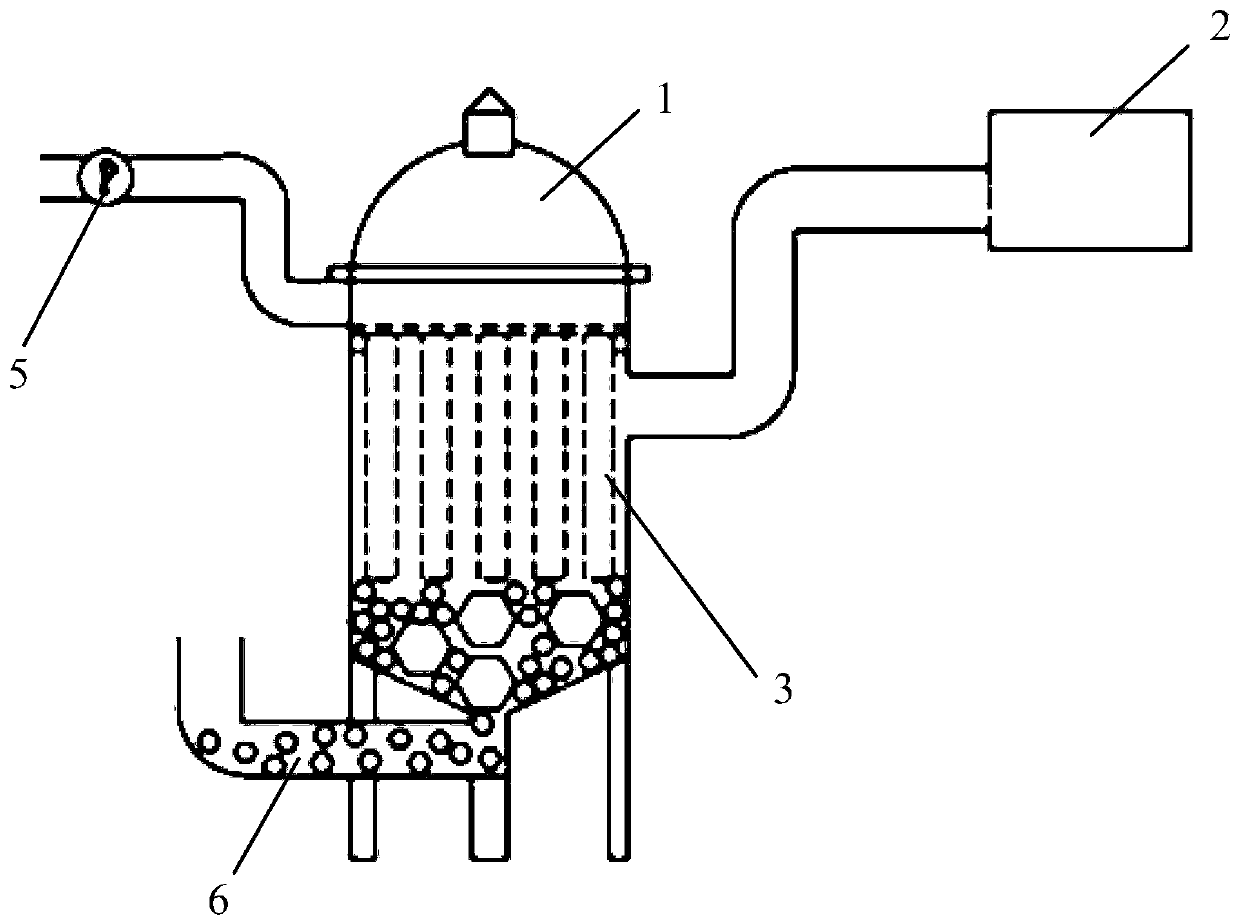

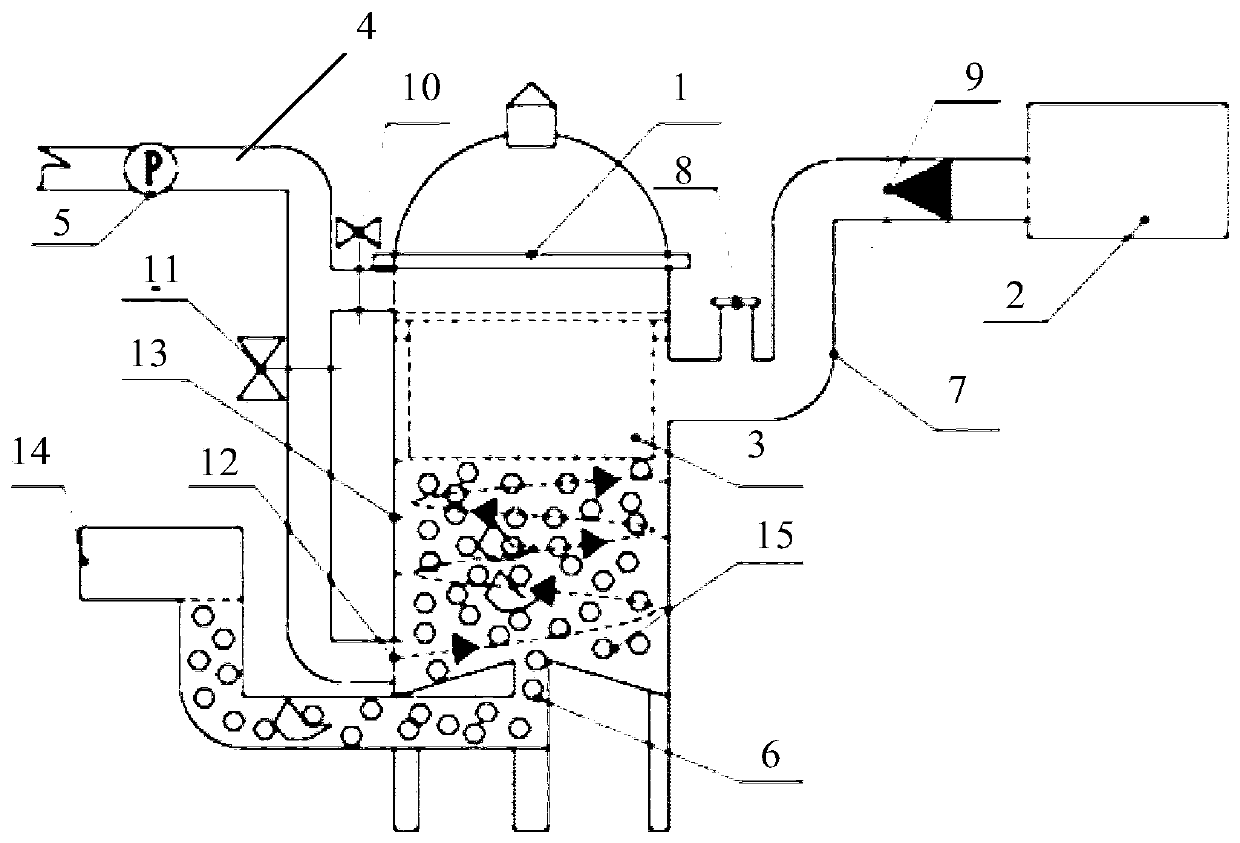

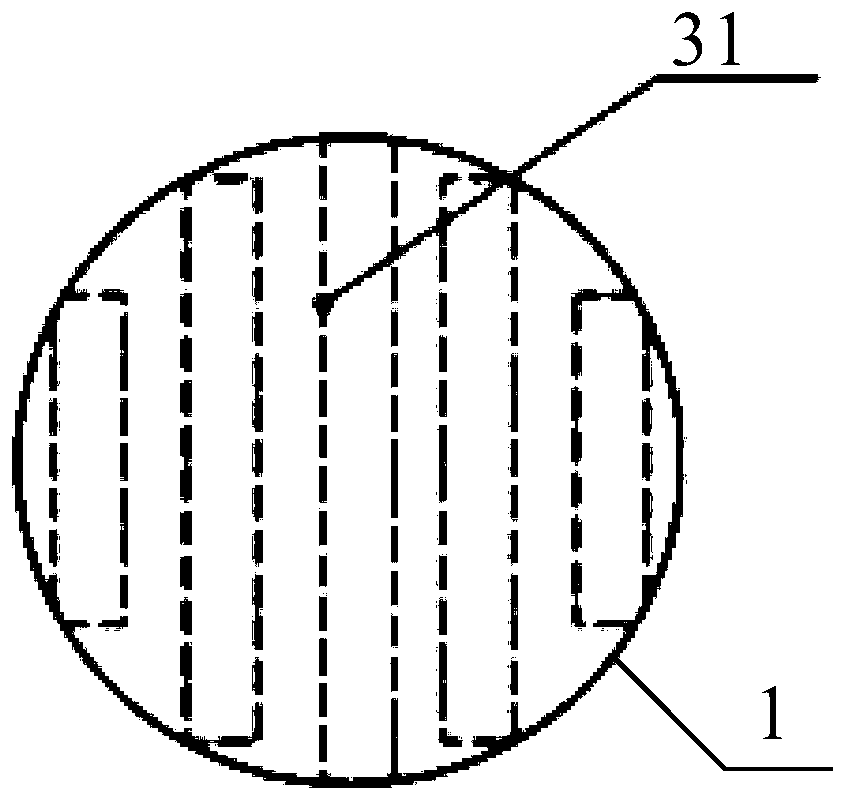

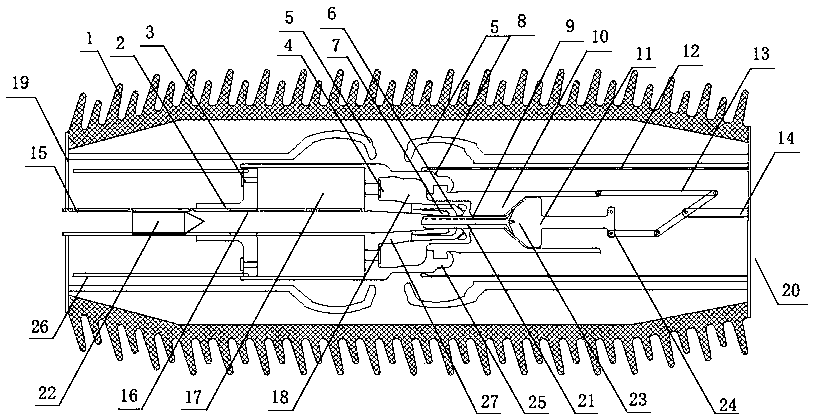

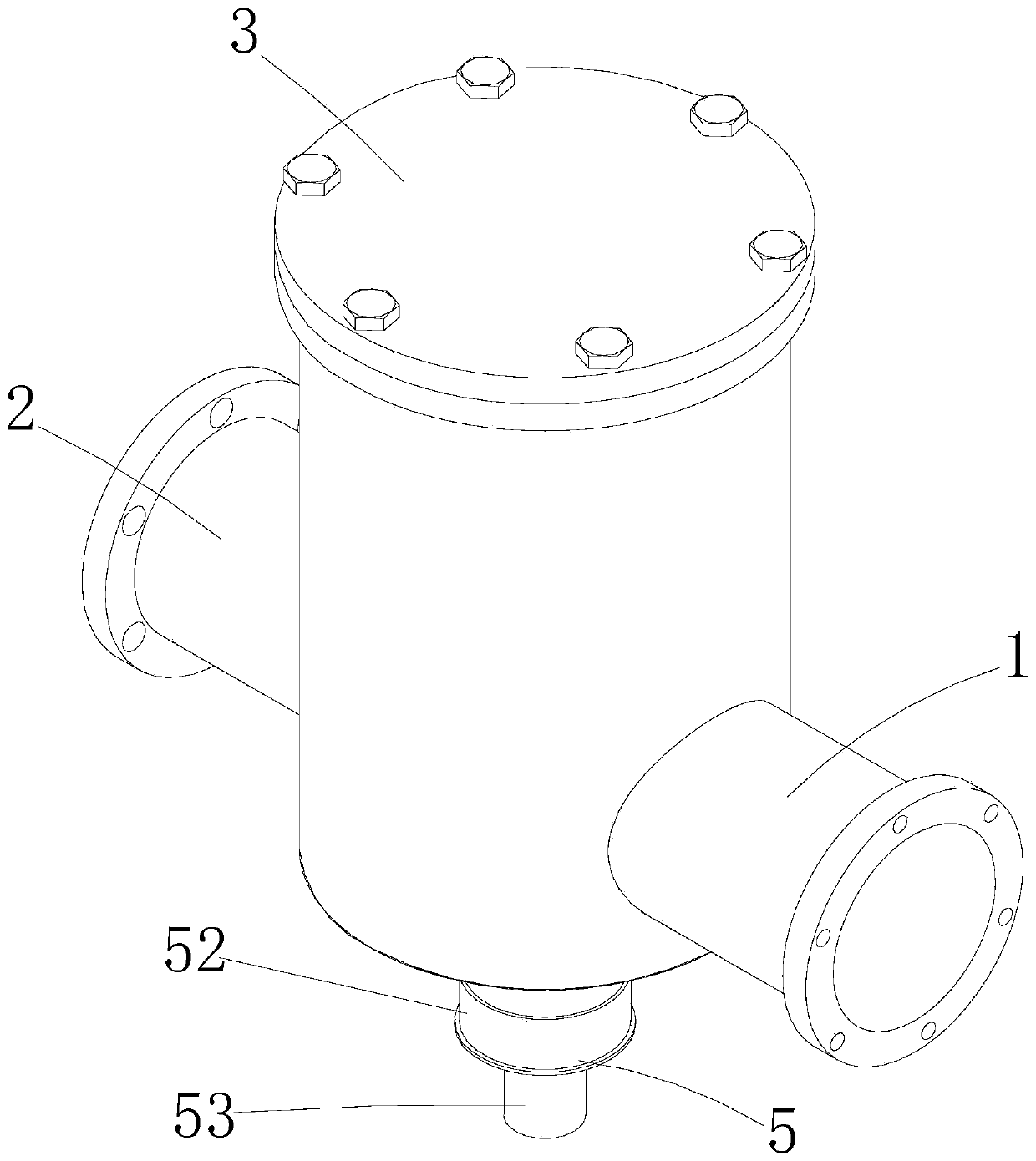

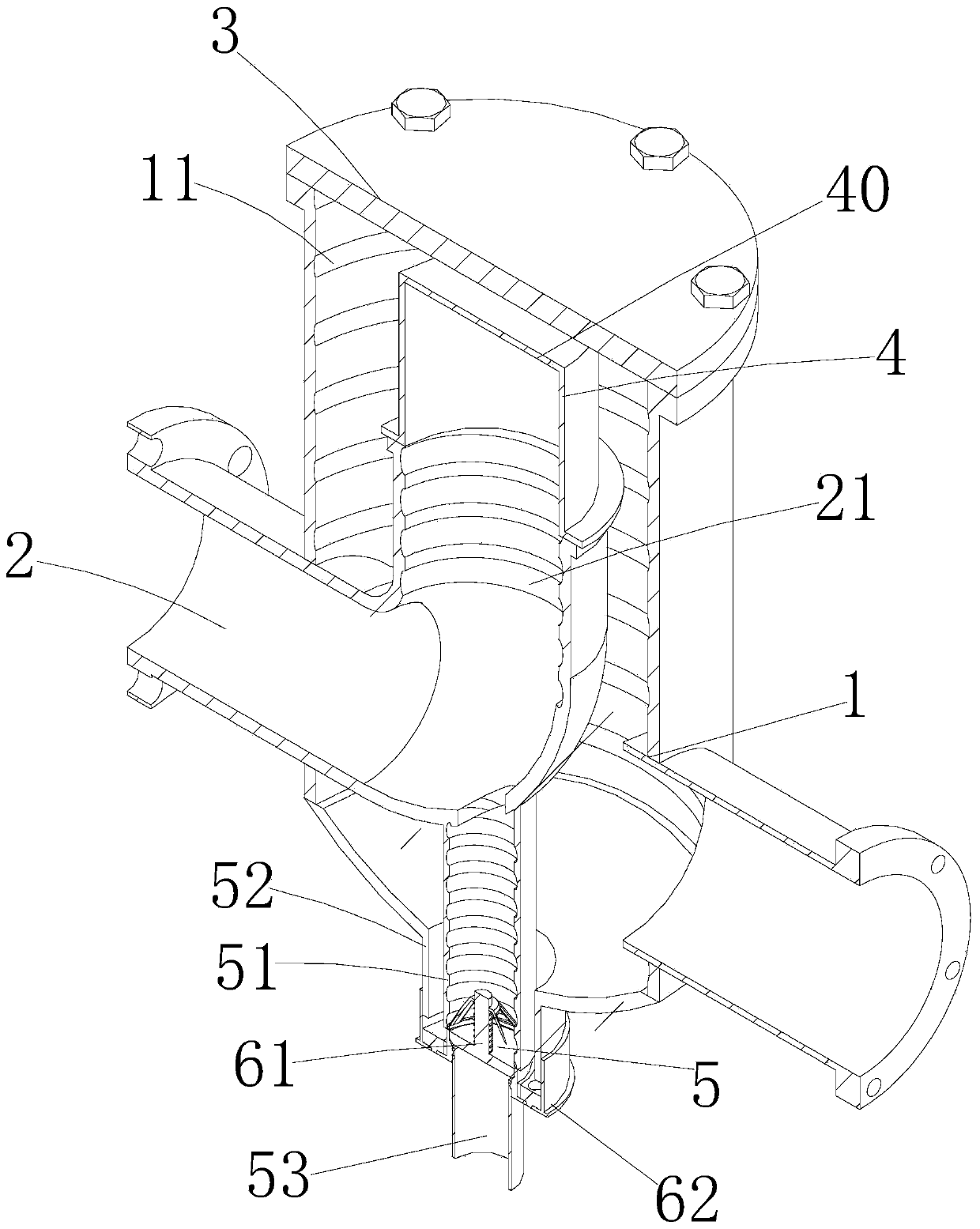

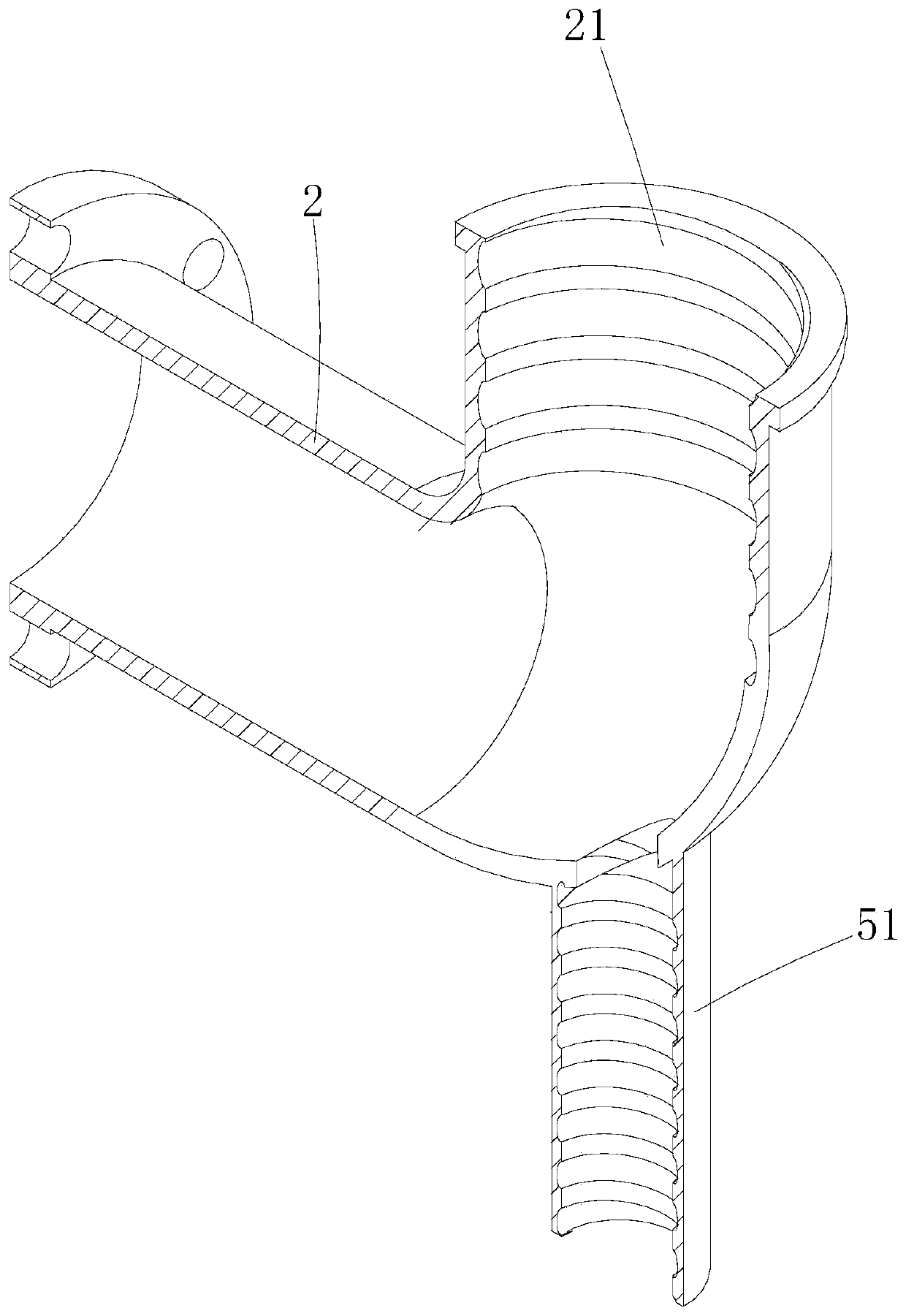

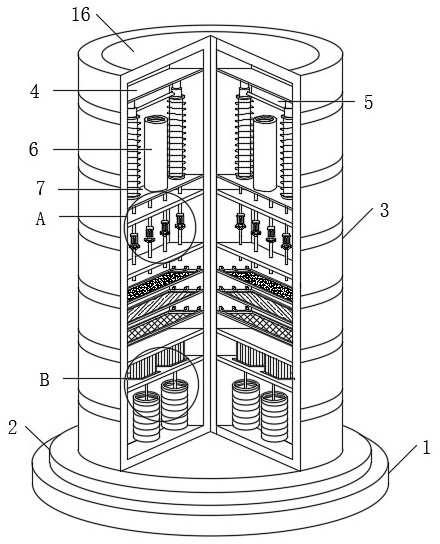

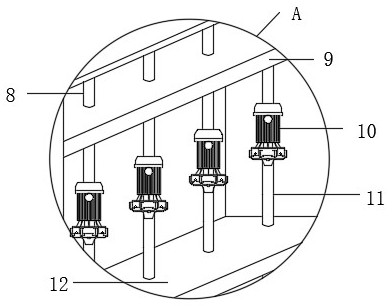

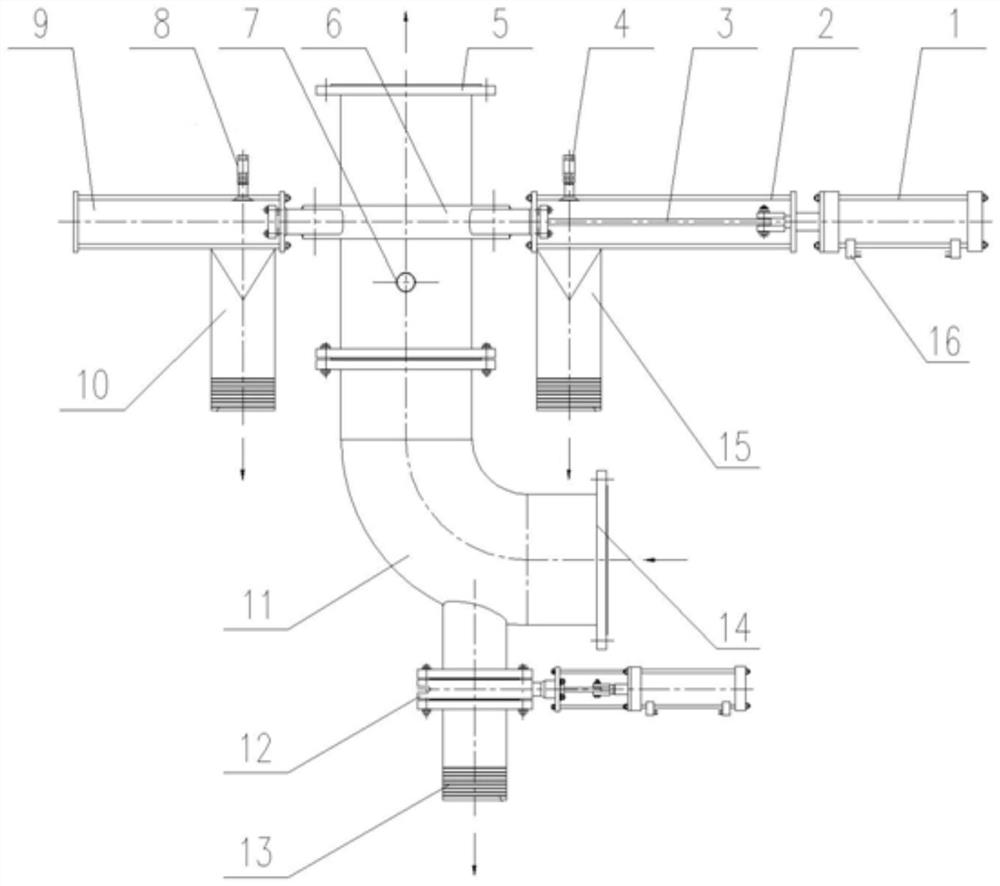

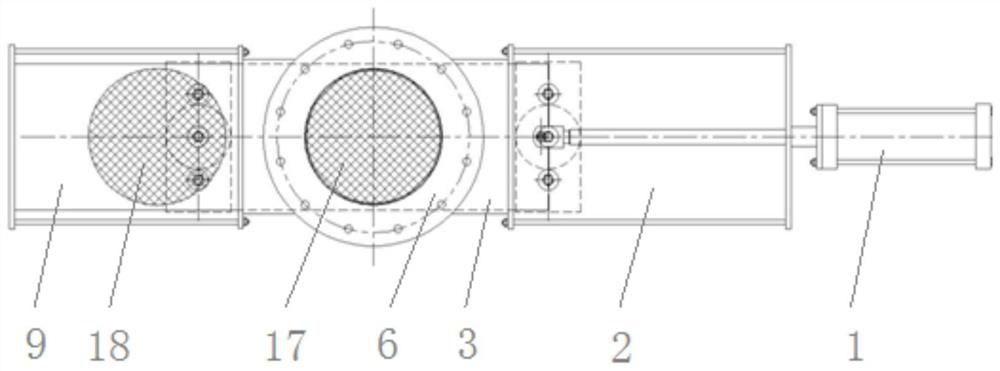

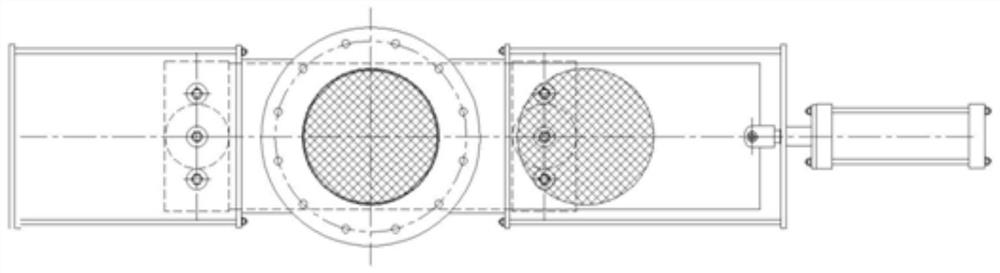

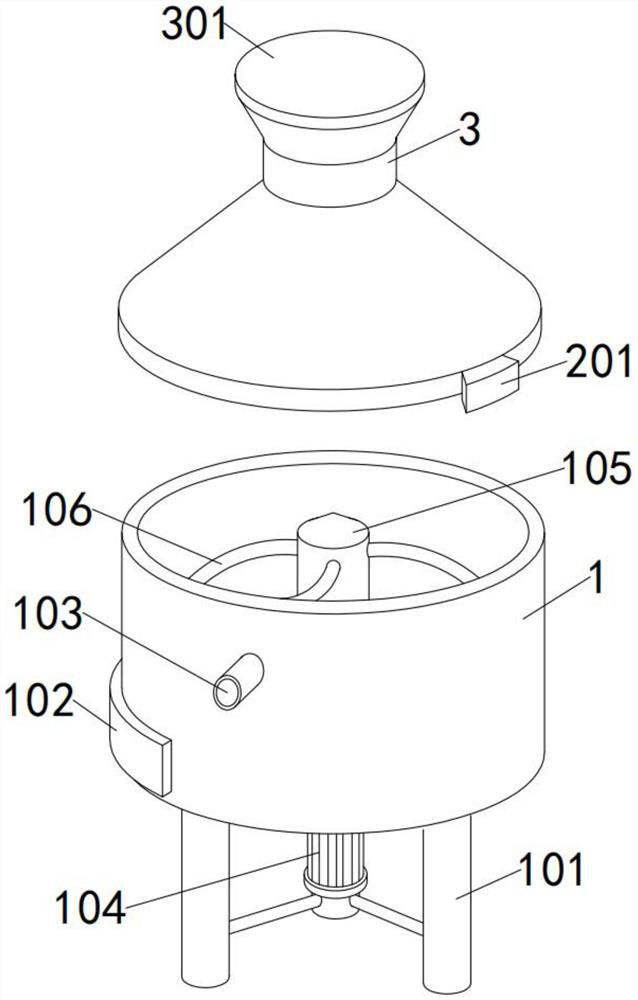

Single crystal furnace dedusting and filtering system

InactiveCN111111333ASmooth dischargeGood dust removalDispersed particle filtrationTransportation and packagingPhysicsPumping vacuum

The invention discloses a single crystal furnace dedusting and filtering system. The system comprises a dedusting tank main body and a vacuum pump assembly, and the dedusting tank main body is communicated with a single crystal furnace, and a filtering unit is arranged in the dedusting tank main body so as to filter a gas discharged by the single crystal furnace; a discharge port for discharging impurity particles is formed in the lower end of the dust removal tank main body; the vacuum pump assembly comprises a vacuumizing pipeline and a vacuum pump arranged on the vacuumizing pipeline; and the vacuumizing pipeline is communicated with the dust removal tank main body, and the vacuum pump assembly is used for vacuumizing the inner cavity of the dust removal tank main body when the single crystal furnace carries out crystal pulling and air blowing air on the inner cavity of the dust removal tank main body when the single crystal furnace finishes crystal pulling. The dedusting and filtering system can effectively discharge impurity particles such as oxide deposited at the bottoms of the filtering unit and the tank man body, prevent the exhaust pipeline from being blocked and improvethe dust removal effect.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

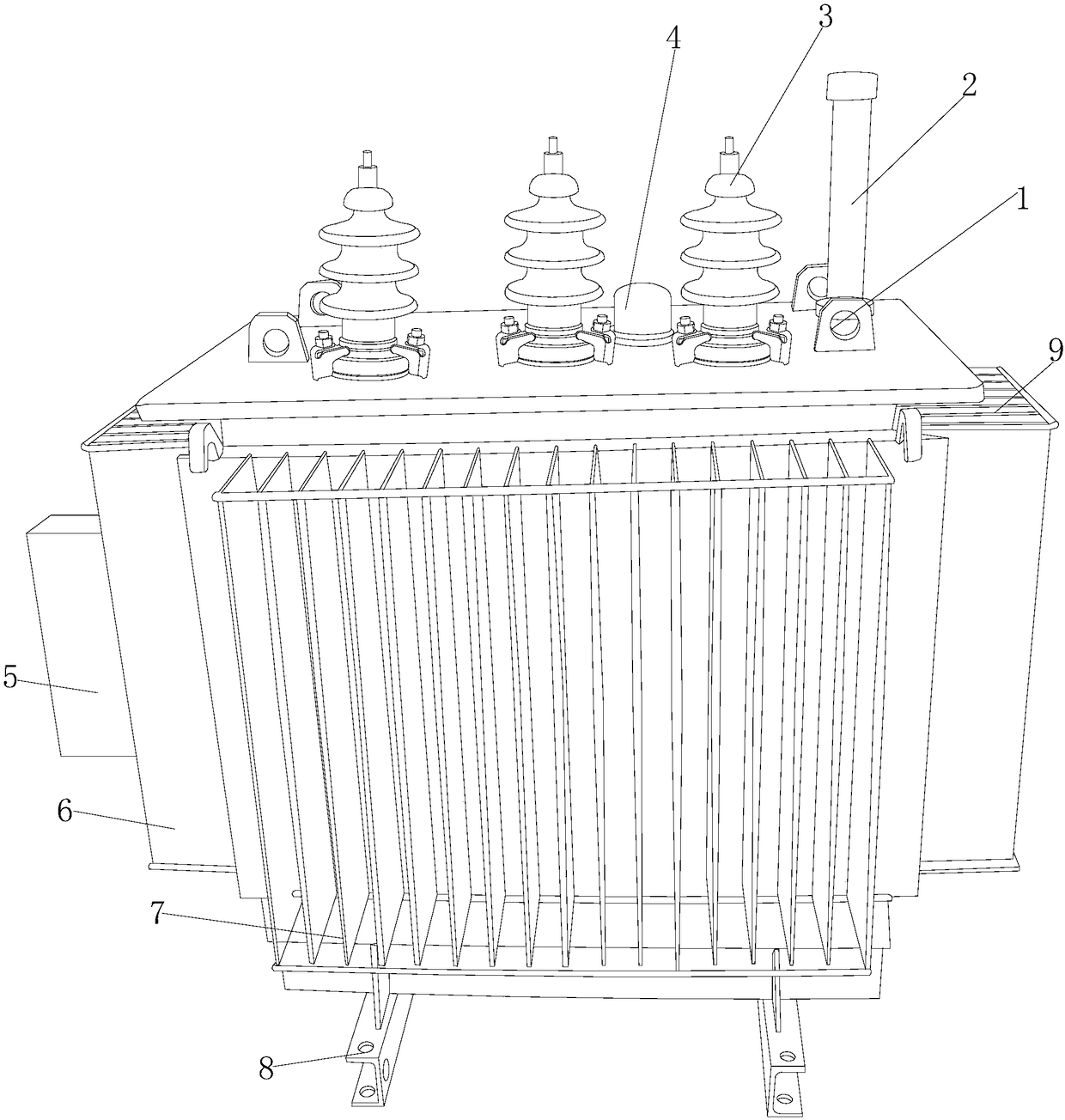

Solar transformer cooling device

InactiveCN108987052AEasy to useEffective coolingTransformers/inductances coolingElectricityLow voltage

The invention discloses a solar transformer cooling device. The structure of the solar transformer cooling device includes: Handles, terminal jackets, low voltage outlet jacket, Tap switch jacket, Battery, transformer housing, heat sink device, bracket, solar panel, A battery is secured to the left side of the transformer housing and the signal terminal on the right side of the battery is electrically connected to the electrical system inside the transformer housing. As that cool device of the solar transformer of the invention is improve, A heat dissipation mechanism inside the device can effectively diffuse cold gas on the stirring and spraying device to the inside of the transformer through a fan, As that component of the internal mechanism of the transformer can be heat dissipated in time, the transformer can be used for a long time, and the use is safe. The invention mainly carry out effective heat dissipation work on the transformer through chemical substances, not only greatly saves the electric energy of the device, but also improves the heat dissipation efficiency of the device.

Owner:刘钰婷

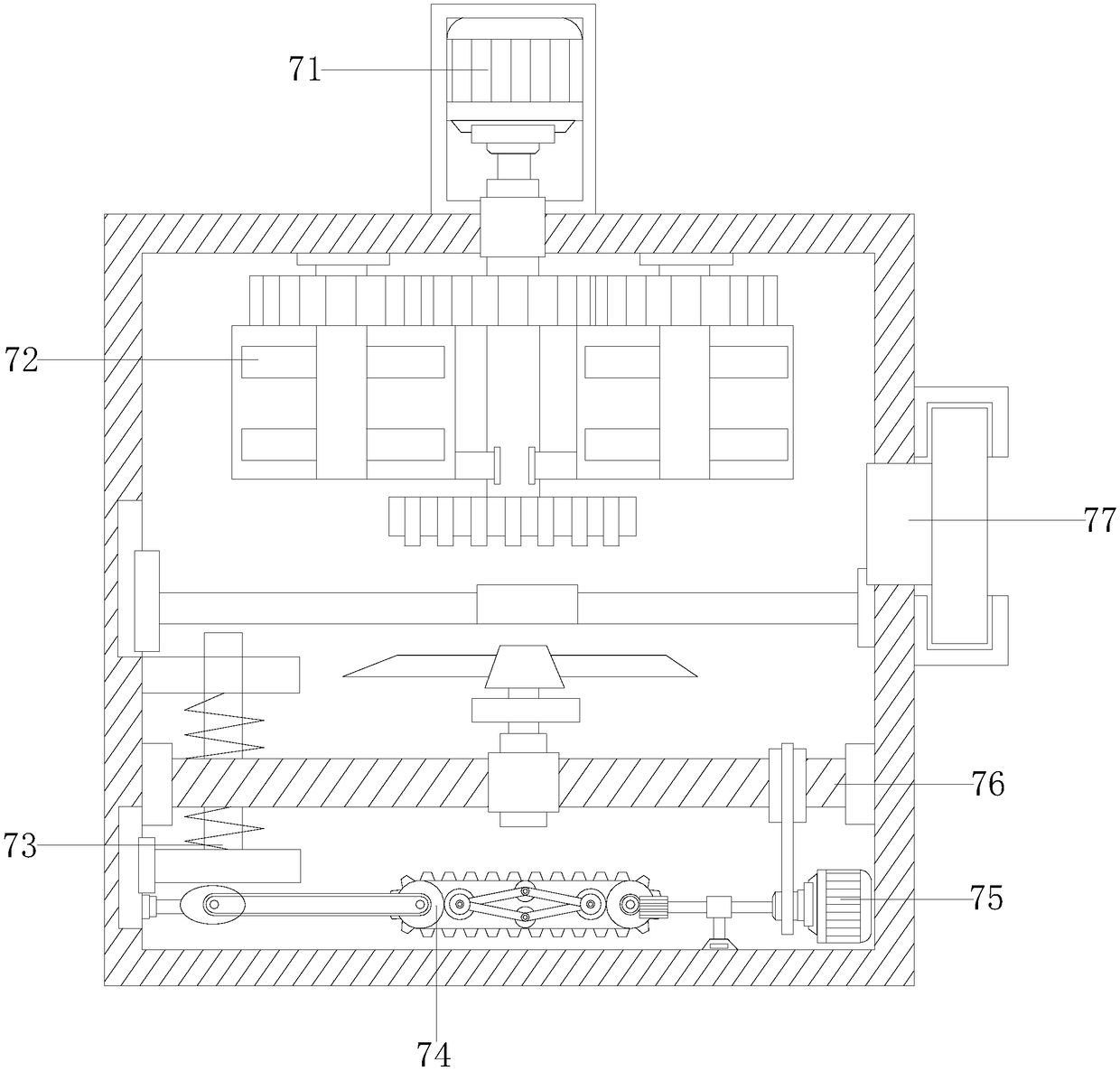

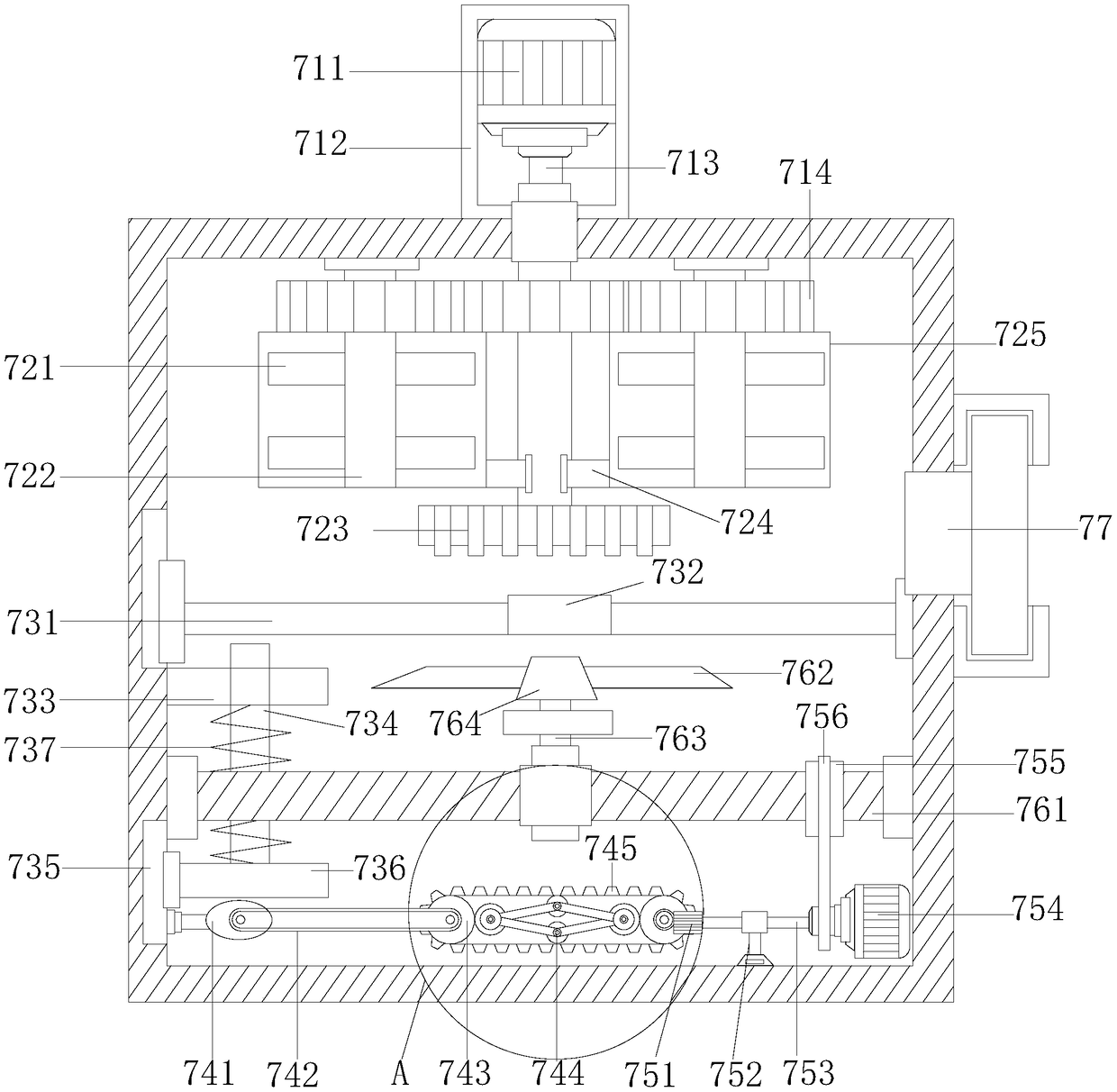

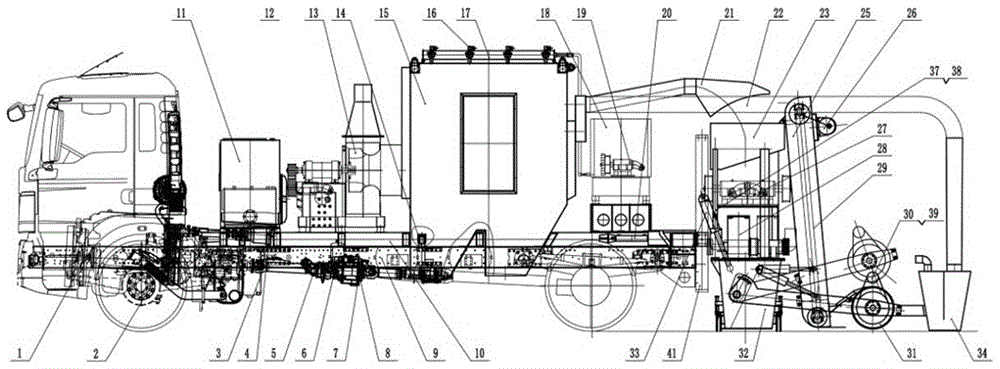

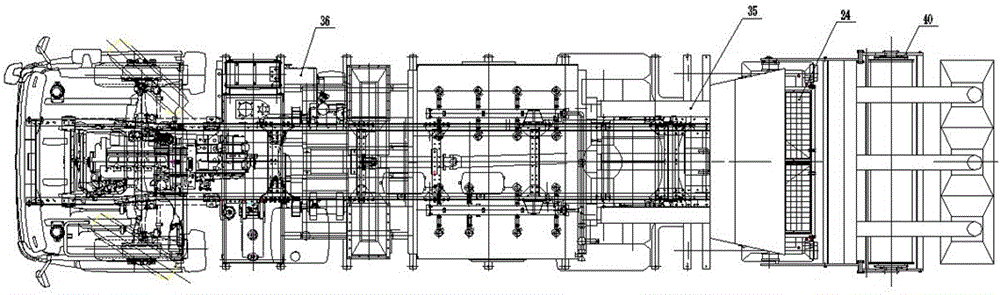

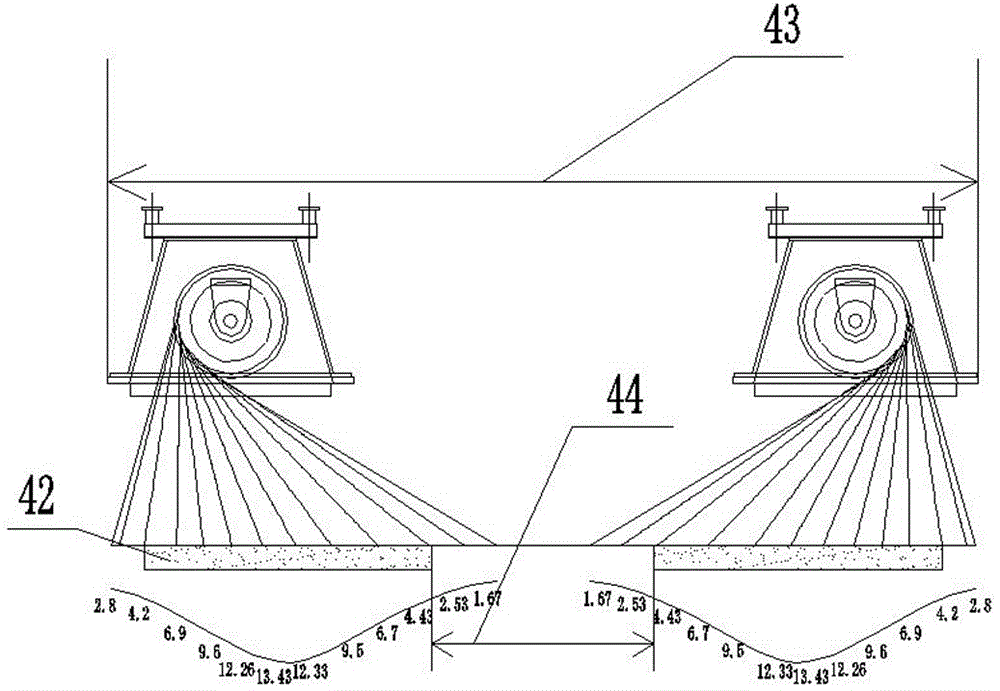

Environmental-friendly pavement regeneration treatment equipment

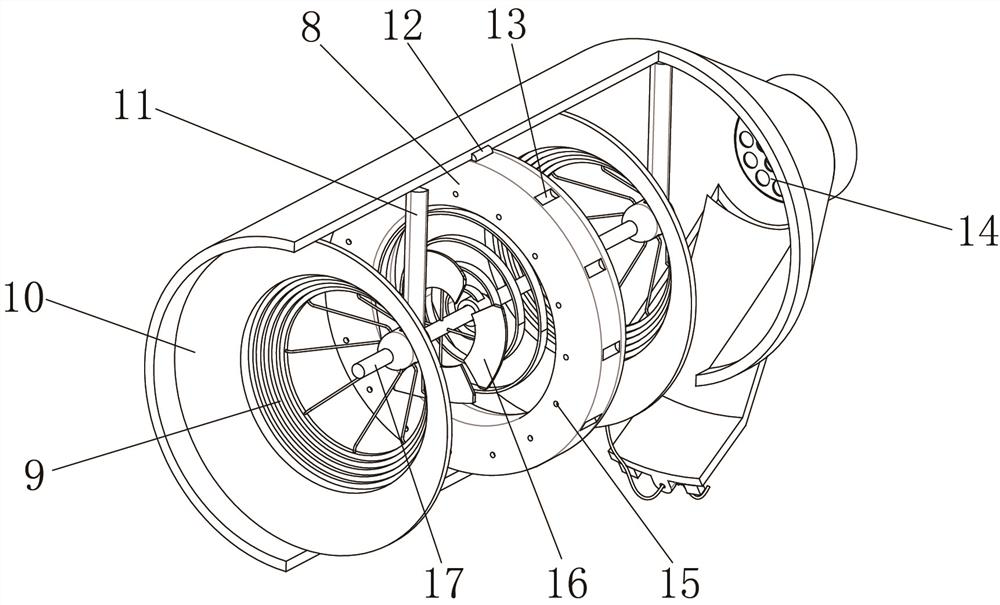

InactiveCN106835921AEfficient separationSolve and recycle at the same timeRoads maintainenceSelf lockingEngineering

The invention discloses environmental-friendly pavement regeneration treatment equipment which comprises a special automotive chassis, a shot-blasting working device, a dust removal device, a lifting device, a mechanical handle and a spin button operation control system, wherein a left shot-blasting unit, a middle shot-blasting unit and a right shot-blasting unit are arranged on the shot-blasting working device; an included angle of 95 degree is formed between each of the three shot-blasting units and the working face; the left and right shot-blasting units are arranged in parallel on the left and right sides of a shot-blasting box in the same direction; the middle shot-blasting unit is reversely mounted at a front position in the middle of the shot-blasting box; the front staggered position distance of the middle shot-blasting unit is just a hot zone width of the shot-blasting unit during operation; the shot-blasting working device is further provided with a magnetic separation device; a dust collection duckbill unit connected with the dust removal device is arranged at the tail part of the magnetic separation device; and two hydraulic self-locking cylinders are arranged in the magnetic separation device. According to the equipment disclosed by the invention, steel grit and dust can be effectively separated from each other, the equipment is simple and convenient in operation, easy to maintain, high in working efficiency, economic and environmental-friendly, the service life of the shot-blasting units is effectively prolonged, and the usage cost is reduced.

Owner:山东一路工程装备科技有限公司

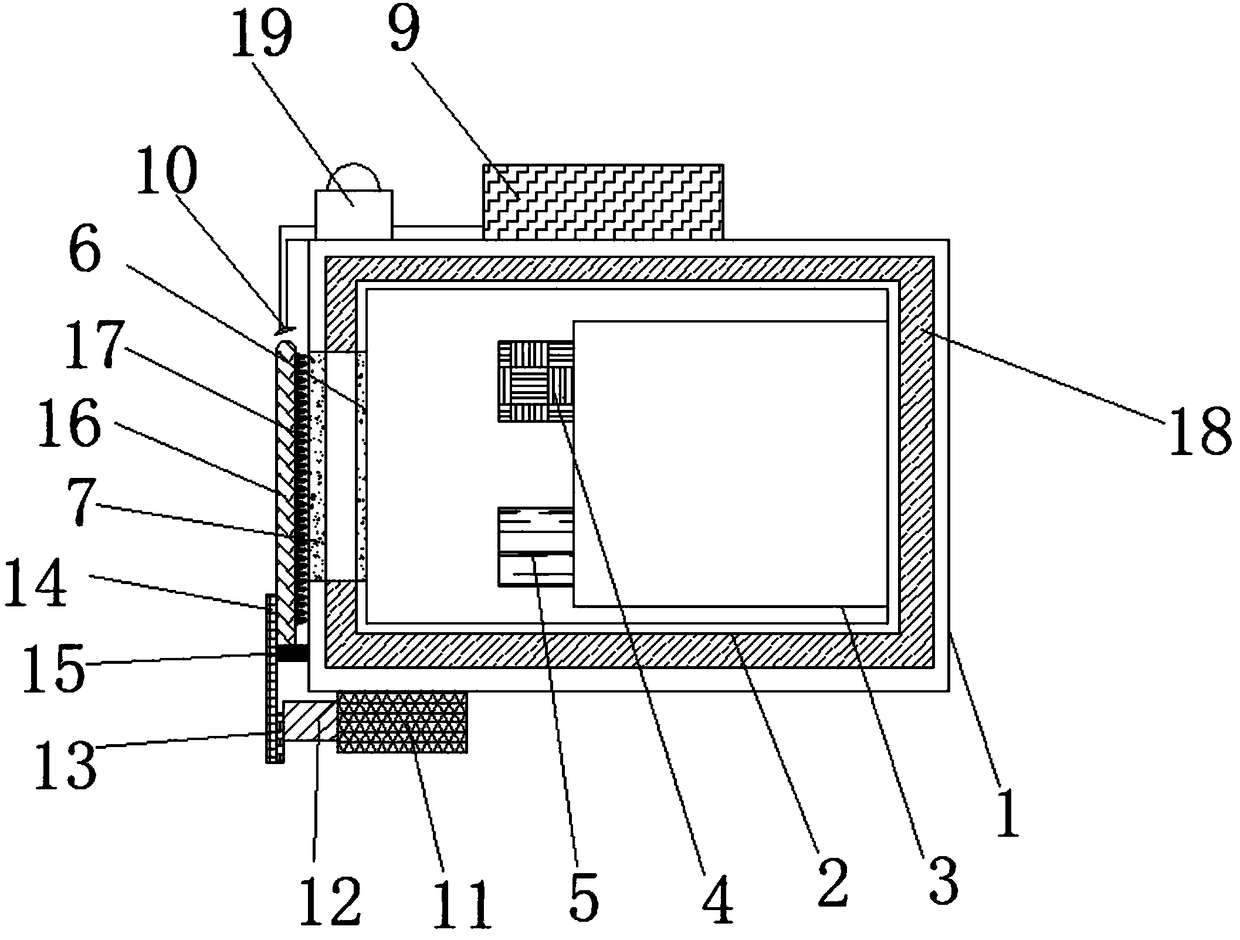

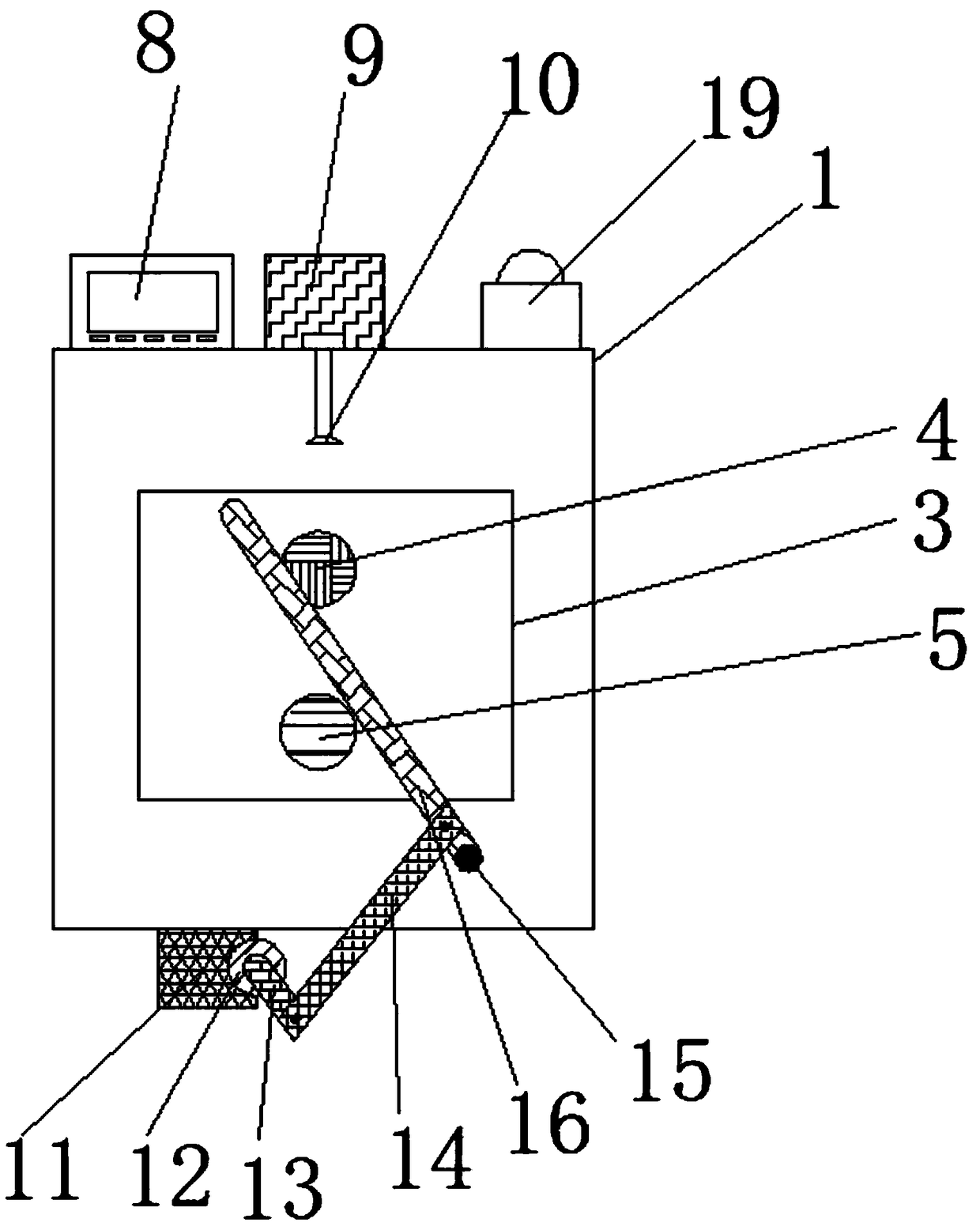

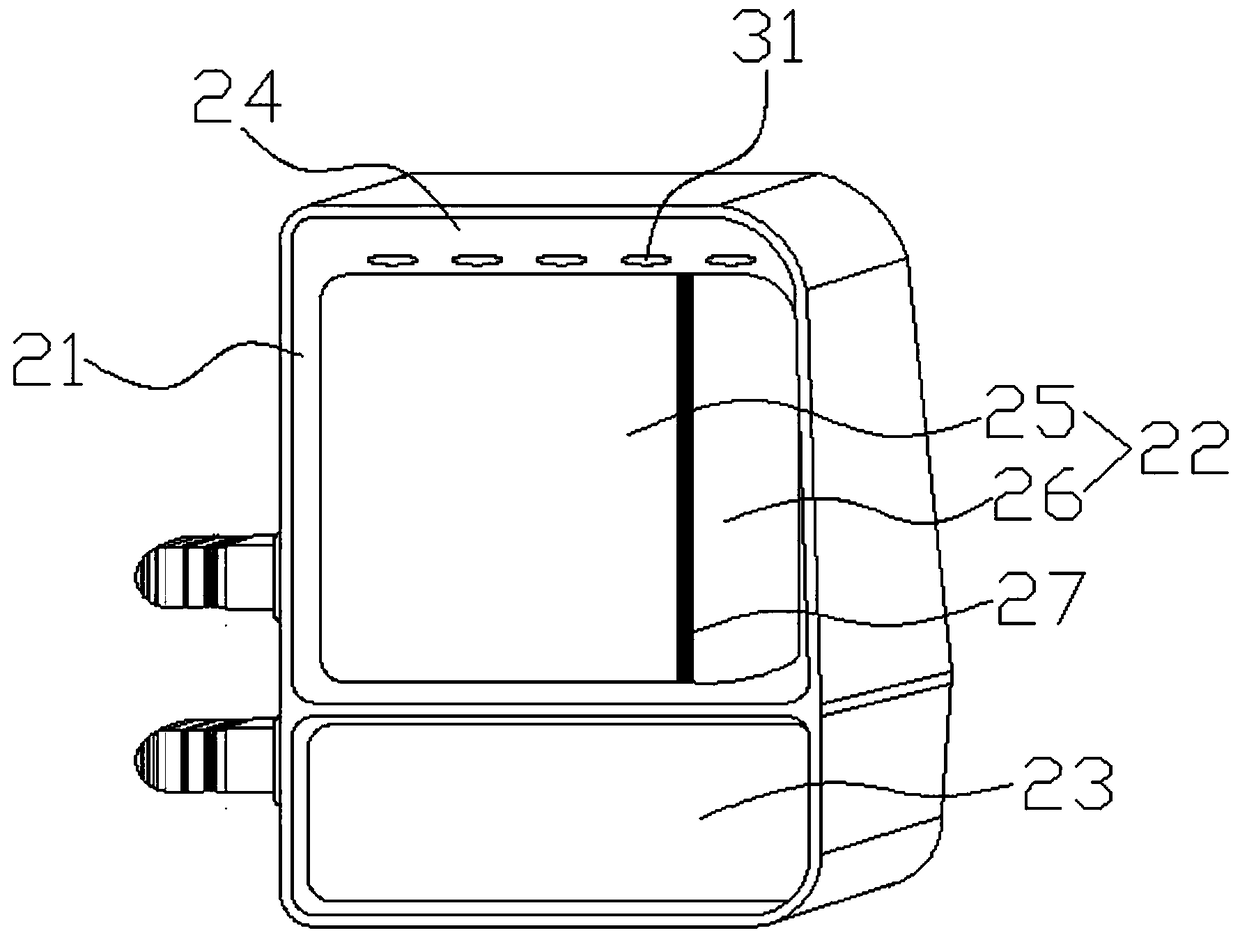

Spark detecting device with self-cleaning effect

PendingCN108318136ADisaster reductionProtection securityFlexible article cleaningCleaning using toolsEngineeringUltraviolet

The invention discloses a spark detecting device with a self-cleaning effect. The spark detecting device comprises an outer casing, an inner casing, a detector body, an ultraviolet photodiode, an infrared photodiode, inner glass and outer glass, wherein the inner casing is fixedly disposed in the inner cavity of the outer casing; a protective layer is fixedly disposed between the outer casing andthe inner casing; the detector body is fixedly disposed in the inner cavity of the inner casing; the ultraviolet photodiode is fixedly disposed on a side of the surface of the detector body; and the infrared photodiode is fixedly disposed on the bottom of the ultraviolet photodiode; the inner glass is fixedly disposed on one side surface of the inner casing; the outer glass is fixedly disposed onone side surface of the outer casing; and a fan is fixedly disposed on the top surface of the outer casing. The outer glass of the spark detecting device can be cleaned by the fan and a ventilation head, and is further cleaned by a movable rod and a brush so that the normal operation of the spark detecting device is guaranteed.

Owner:浙江欧康电子信息技术有限公司

Self-energy dual-acting arc extinguishing chamber

PendingCN110071012ASmall sizeEffective blowingHigh-tension/heavy-dress switchesAir-break switchesSelf-energyHigh pressure

The invention relates to a self-energy dual-acting arc extinguishing chamber, and belongs to the technical field of a high-voltage switch. The automatic arc extinguishing chamber comprises a movable end part and a static end part, wherein the movable end part comprises a movable end pull rod, an air cylinder, an expansion chamber and an auxiliary nozzle, the static end part comprises a static arccontact, an arc extinguishing nozzle and a connection rod structure, the auxiliary nozzle is fixedly connected with the arc extinguishing nozzle, the static arc contact can be driven to achieve equal-speed deviation motion during the motion process of the movable end pull rod, the static arc contact is provided with a piston, an outer wall of the piston is matched with an inner wall profile of thearc extinguishing nozzle, a gap is formed between the outer wall of the piston and the inner wall profile, an air guide passage is formed in the static arc contact and communicates with a surface ofthe piston from an axis, high-voltage gas generated by an arc flows into an enclosed region formed between the piston and the arc extinguishing nozzle through the air guide passage, and the capacity of the expansion chamber is equivalently expanded. The self-energy dual-acting arc extinguishing chamber is provided with the air cylinder, the expansion chamber and an auxiliary piston, a three-air chamber structure is formed during the breaking process, the arc extinguishing speed is rapid, and an effect is good.

Owner:SHENYANG POLYTECHNIC UNIV

Paper conveying device for color printing capable of eliminating electrostatic adsorption

InactiveCN112897187APrevent static electricityEasy to transportCleaning using gasesElectrostatic chargesColor printingPaper dust

The invention discloses a paper conveying device for color printing capable of eliminating electrostatic adsorption, comprising an operation table board. A limiting channel is arranged at the lower end of one side of the operation table board. An operator starts the machine through a control button on a control panel, numerical values can be observed on a display screen, and paper is conveyed to a conveying opening through a machine body; a cutting device on one side can effectively cut the paper in time in the using process, so that the convenience of the paper in the conveying process is guaranteed, and subsequent paper storage is facilitated; by means of an anti-static device on one side, in the paper conveying process, adhesion between the paper can be reduced, the humidity between the paper can be effectively guaranteed, and conveying between the paper is facilitated; the paper is conveyed through the operation table top, and workers can take the paper; and by means of an air blocking and blowing device on one side, during use, cleaning of a conveying panel can be guaranteed, air is effectively blown, paper scraps and residues on the panel can be cleaned, the conveying convenience is improved, and the use convenience of the next time is guaranteed.

Owner:沈梦飞

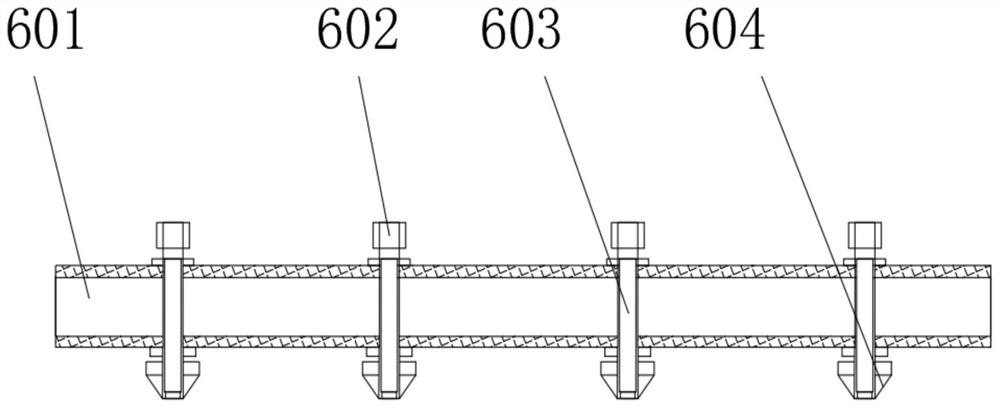

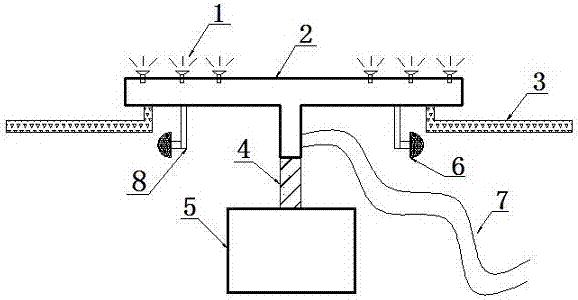

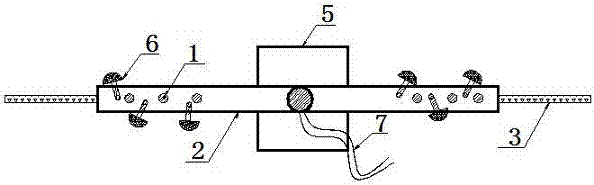

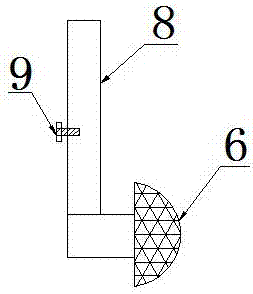

Spraying machine for plant protection

The invention provides a spraying machine for plant protection. The equipment comprises a spraying rod, a motor, a fan and a hose, wherein the spraying rod is T-shaped; the spraying rod is a sealed hollow rod; the spraying rod is grafted on a spindle of the motor; the spindle extends out from the motor; the rotation direction of the spindle is converted periodically; the fan is installed under the spraying rod; the fan blows wind along a horizontal divergence direction of rotation of the spraying rod; a connecting rod of the fan is a telescopic rod; a screw fastening part is disposed on the connecting rod; the hose is connected to and communicates with the spraying rod; the hose is connected to the lower end of the vertical part of the T-shaped spraying rod; and spraying nozzles are disposed on the spraying rod and distributed on two ends of the spraying rod. According to the invention, the structure is simple; the cost is low; spraying orientations are complete; effects are good; spraying efficiency is greatly increased; and thus energy consumption in spraying is reduced, and use cost is reduced.

Owner:合肥市老海新材料有限公司

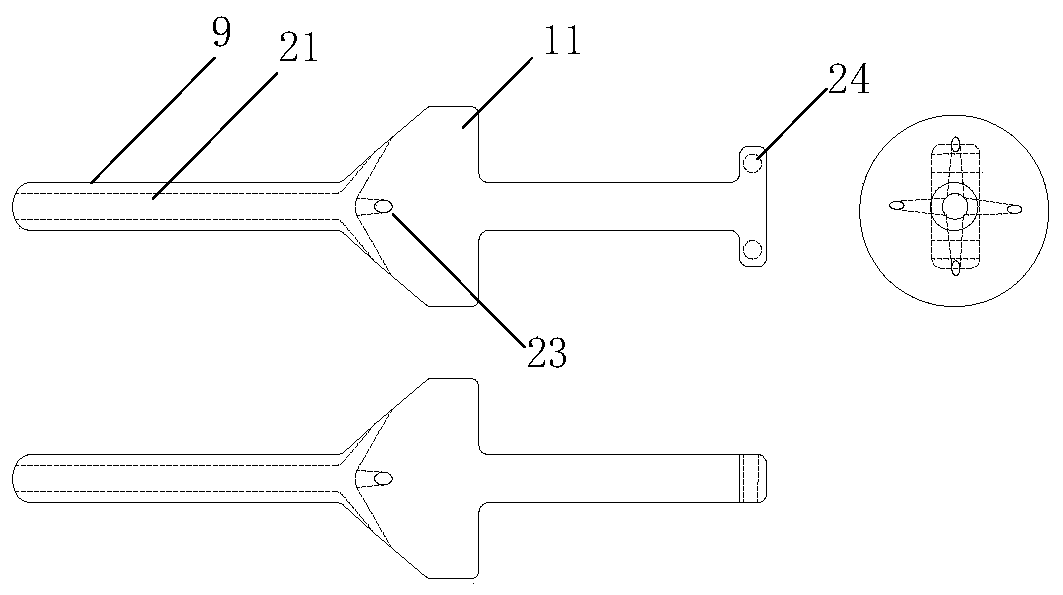

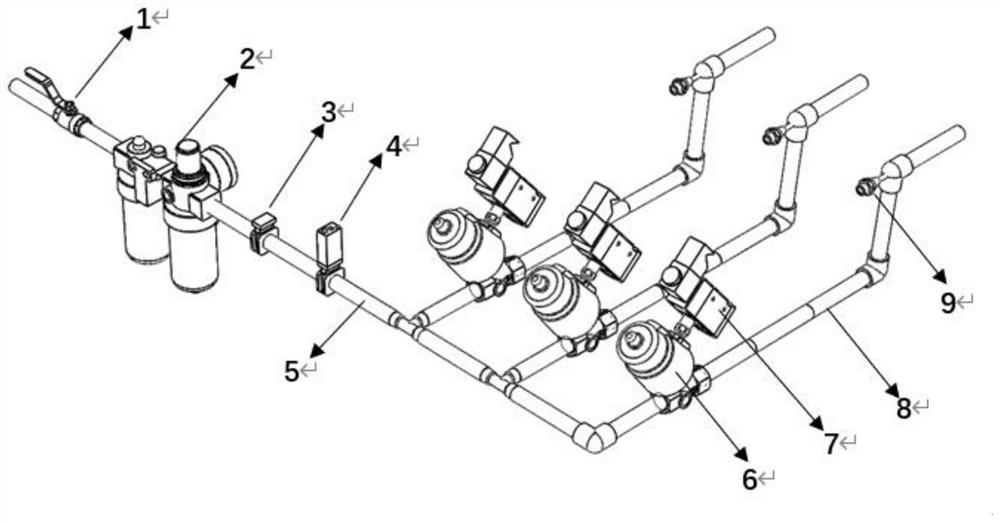

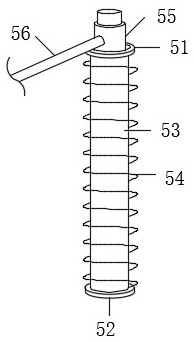

Steeper liquid level probe spraying and blowing device

PendingCN113796562AEffective blowingThe control method is scientific and reasonableTobacco preparationCleaning using gasesEngineeringMechanics

The invention discloses a steeper liquid level probe spraying and blowing device. The steeper liquid level probe spraying and blowing device comprises an air inlet pipe, temperature detectors and an electromagnetic stop valve, wherein three air outlet pipes are arranged on the air outlet end side of the air inlet pipe, and the three air outlet pipes are correspondingly installed in a low liquid level hole, a middle liquid level hole and a high liquid level hole of a steeper respectively; the temperature detectors are respectively arranged in the air outlet pipes in the three liquid level holes; the electromagnetic stop valve is arranged on the air inlet pipe and used for opening or closing a compressed air channel of the air inlet pipe. The device is advantaged in that impurities attached to a liquid level hole and a temperature probe of the impregnator can be effectively cleaned and blown, and smooth production is guaranteed.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

Hot air drying equipment for electrolytic copper foil production

InactiveCN114322519ASimple structureEasy to useDrying gas arrangementsDrying machines with progressive movementsCold airTemperature control

The invention discloses hot air drying equipment for electrolytic copper foil production, relates to the technical field of electrolytic copper foil production, and is used for solving the technical problems that copper foil acid mist points affect copper foil quality and water vapor on the surface of copper foil affects production efficiency in an existing copper foil production mode. Comprising a cathode roller, a winding guide roller, a water pressing roller, an air blowing device and a detection device, the air blowing device is installed on the outer side of the cathode roller and located between the winding guide roller and the water pressing roller, and the air blowing device comprises a hot air opening facing the water pressing roller and a cold air opening facing the winding guide roller; the detection device detects the acid mist concentration of the water pressing roller area and the copper foil temperature of the winding guide roller area and controls the air volume and the air outlet temperature of the hot air opening and the cold air opening according to the detected acid mist concentration and the detected copper foil temperature. The hot air drying equipment for electrolytic copper foil production is simple in structure and convenient to use, the quality and production efficiency of copper foil are effectively improved, and the hot air drying equipment has very high practicability.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

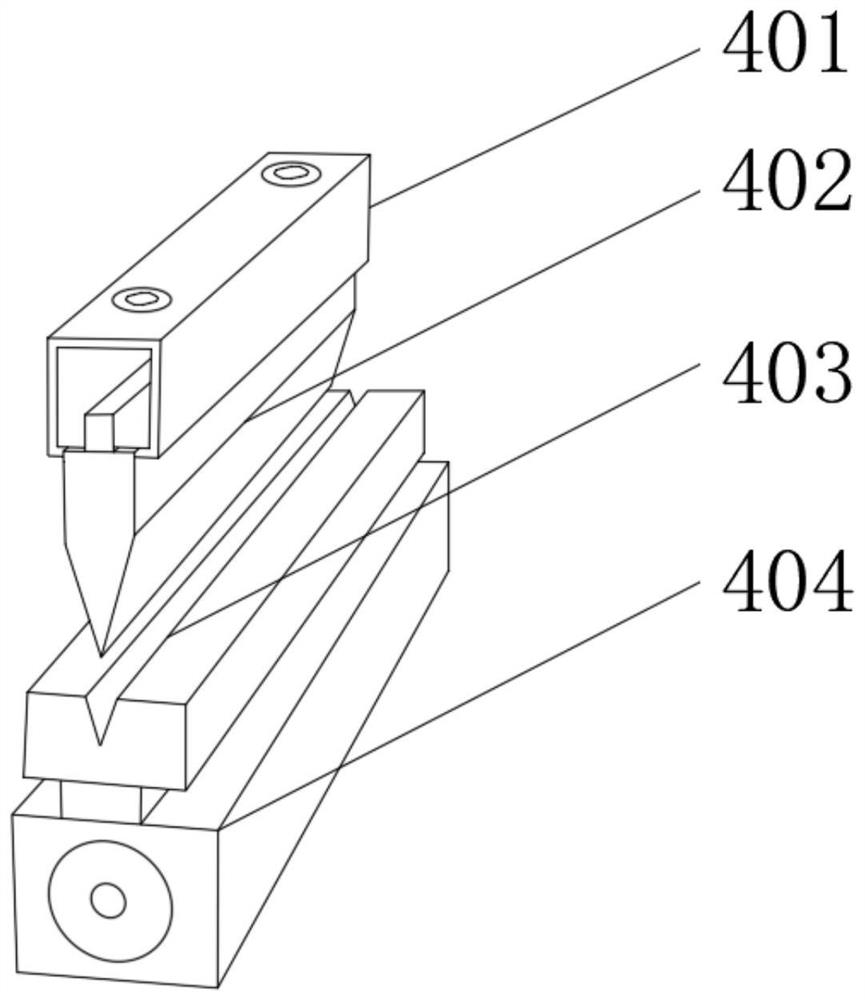

Grinding equipment for automobile manufacturing

InactiveCN111482878AQuick breakEffective blowingGrinding carriagesGrinding drivesAirbagAutomotive manufacturing

The invention discloses grinding equipment for automobile manufacturing, and relates to the technical field of automobile manufacturing. The grinding equipment specifically comprises a grinding table,grinding rollers, lifting rods and pressing devices. Sliding grooves are formed in the bottom face of the grinding table at equal distance. A transmission groove is formed in the front portion of thegrinding table. Each grinding roller comprises a roller core and a grinding sleeve. Airbags are mounted between the adjacent grinding rollers. Rotating rods are mounted on the two sides of the top end of each first supporting rod. The lifting rods are mounted on the inner sides of the rotating rods. A datum plate is mounted on the inner sides of the top ends of second supporting rods. A slip groove is formed in a sliding seat, and the pressing devices are mounted on the inner side of the slip groove in a cooperation manner. According to the grinding equipment for automobile manufacturing, through the arrangement of the grinding rollers, auto parts are ground, the grinding sleeves are convenient to dismount and mount, parts can be ground in the rotating process, and parts can be transferred and conveyed to next positions in the part grinding process.

Owner:DONGGUAN XIANGFEI INTELLIGENT EQUIP TECH CO LTD

Natural gas filter

InactiveCN111530180AExtension of timeEfficient suctionDispersed particle filtrationTransportation and packagingEnvironmental engineeringPetroleum engineering

The invention discloses a natural gas filter which comprises an L-shaped gas inlet pipe fitting, and a pollution discharge structure. Natural gas containing impurities enters the natural gas filter through the gas inlet pipe fitting. The pollution discharge structure is used for blowing out air to a filter element from inside to outside so as to blow off solid impurities attached to the outer wallof the filter element, and meanwhile, the solid impurities are blown out from the bottom of the gas inlet pipe fitting. The air is fed into the filter element, the solid impurities adhered to the outer wall of the filter element are blown to float, and the solid impurities on the outer wall of the filter element can be effectively blown out in the process, so that filter holes are kept unblocked,the time for taking out the filter element for cleaning is prolonged, the working procedure required by cleaning is saved, and the filtering effect of the filter element on the natural gas can also be improved.

Owner:杭州昕华信息科技有限公司

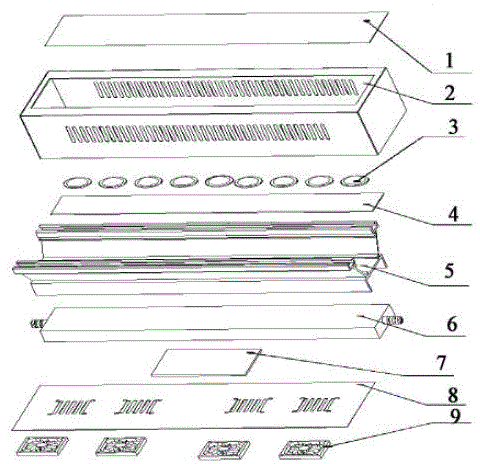

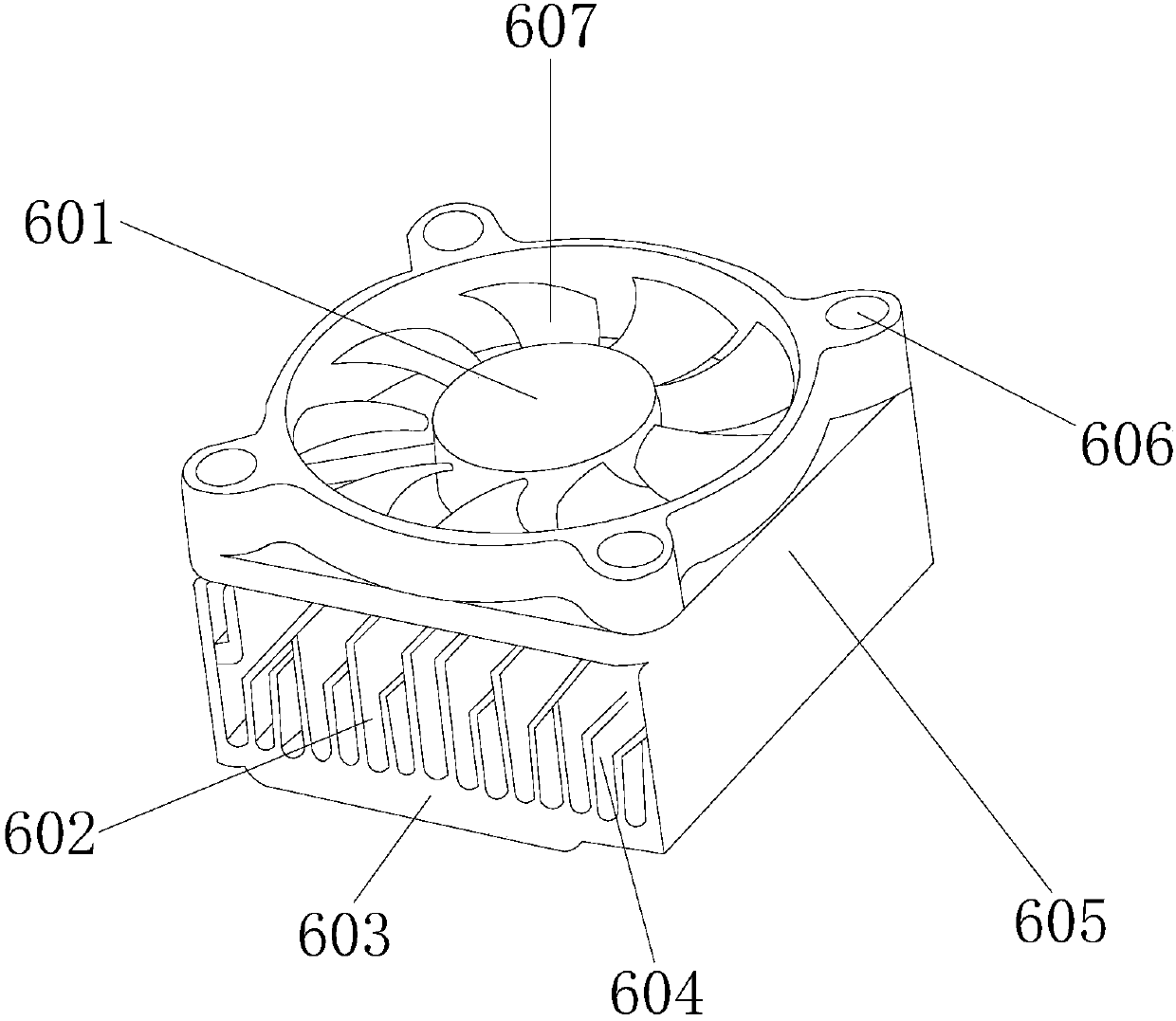

Dispersed light source radiating type LED assembled lamp

InactiveCN104565947AGood light transmissionPure colorPoint-like light sourceLighting heating/cooling arrangementsEngineeringAluminum substrate

The invention discloses a dispersed light source radiating type LED assembled lamp. The dispersed light source radiating type LED assembled lamp comprises an acrylic sheet, a lamp box, an LED lamp bulb, a PCB aluminum base board, a lamp trough, a radiator, a circuit board, a lamp box top cover and a fan; the acrylic sheet completely covers the bottom part of the lamp box; the LED lamp bulb is positioned in the lamp box; the lamp trough comprises two inner concave grooves; the PCB aluminum base board is positioned on the top part of the LED lamp bulb and clamped into one of the inner concave grooves of the lamp trough; the radiator is clamped into another inner concave groove of the lamp trough; the circuit board is positioned between the radiator and the lamp box top cover; the fan is positioned at the outer side of the lamp box top cover. The dispersed light source radiating type LED assembled lamp is reasonable in design; the light sources are dispersed; the lamp bulb and a power supply can be radiated; therefore, the service life and safety of the LED lamp can be prolonged and improved.

Owner:南通奥特机械设备有限公司

A paint spray booth for panel furniture processing

ActiveCN112024259BAchieve clamping and fixingAffect temperatureSpray boothsStructural engineeringScrew cap

The invention relates to the technical field of paint-baking booths, and discloses a spray-baking paint booth for panel furniture processing, which includes a bottom plate, a room body is fixedly connected to the top surface of the bottom plate, windows are fixedly installed on the side of the room body, and Both sides of the body are provided with installation grooves, and the insides of the two installation grooves are respectively fixedly installed with an inlet fan and an outlet fan. The paint spray booth for panel furniture processing uses a movable frame in the installation slot on the side of the fan, and a No. 1 filter plate is fixedly connected to the side of the movable frame, so that a sponge located outside the filter plate is added inside the movable frame. , by using the No. 1 bolt and the socket of the movable plate, the clamping plate can be clamped and fixed to the sponge. When the outside air is sucked into the room, the moisture in the air will be absorbed by the sponge, so as to avoid the influence of moisture entering the room. The temperature inside the room, and when replacing the sponge, unscrew the No. 1 nut and take it out, easy to replace and reusable, and the use effect is good.

Owner:山东凯迪威家具有限公司

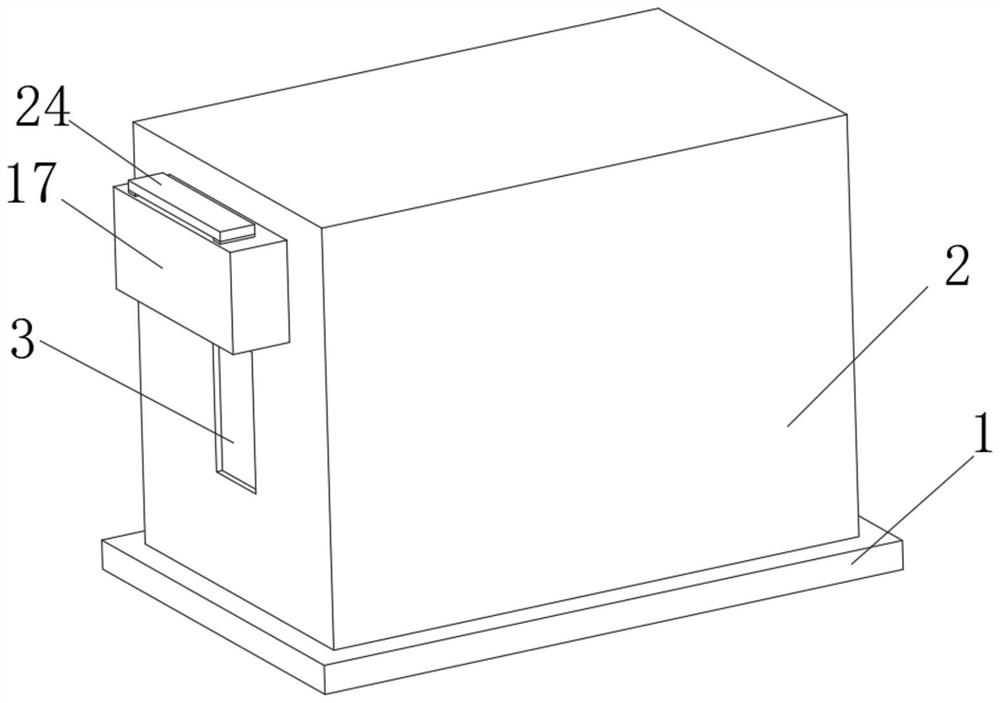

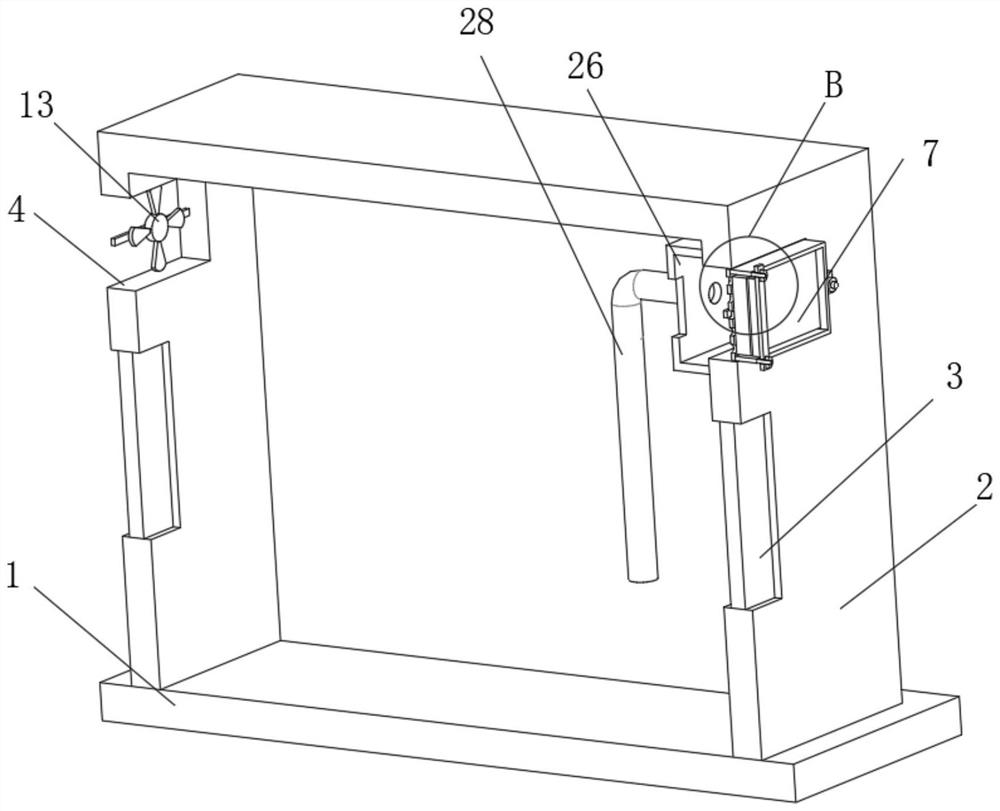

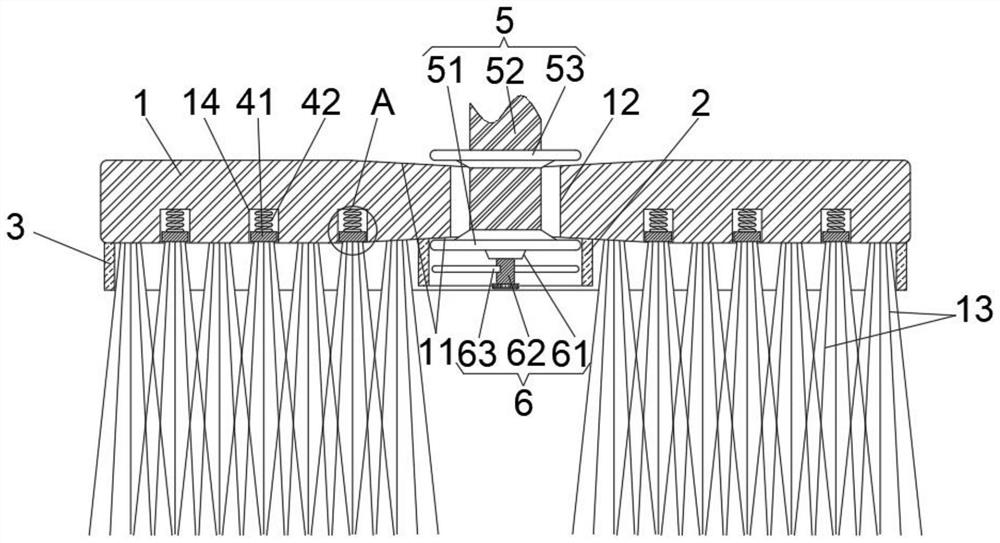

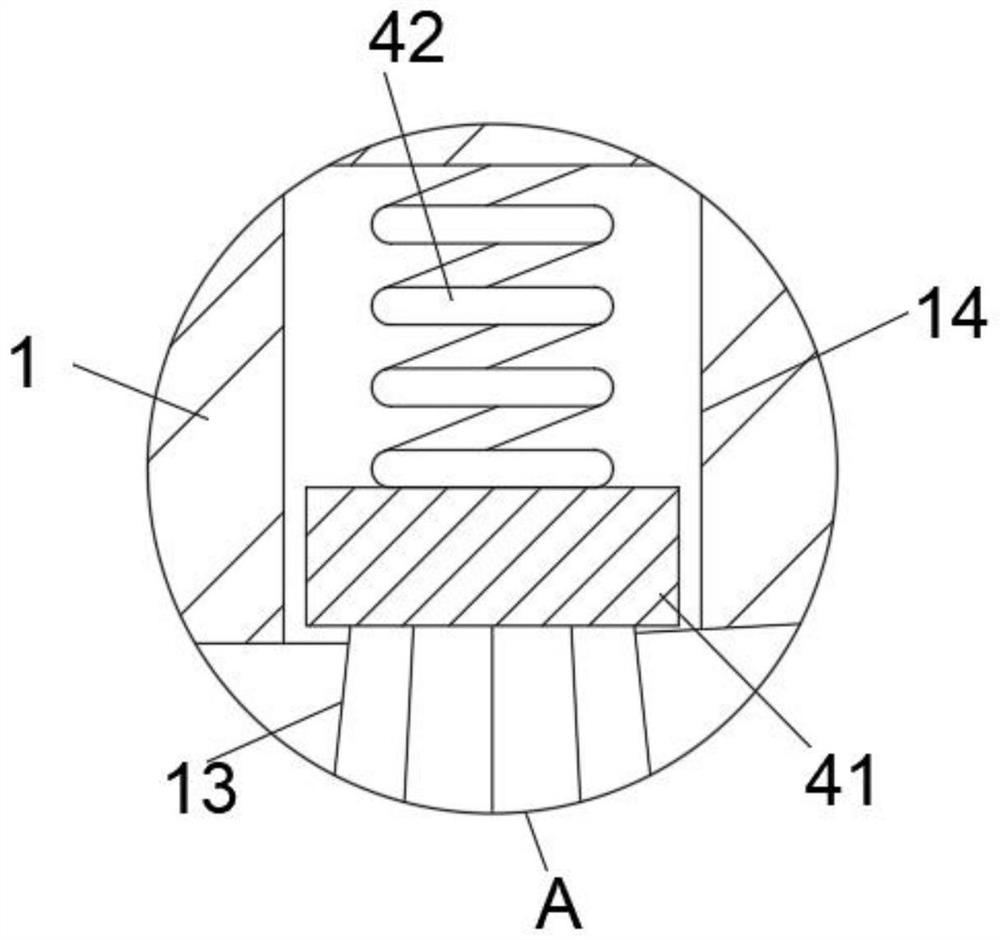

Industrial polishing brush for plate processing

InactiveCN112548815AImprove polishing effectUniform polishingPolishing machinesGrinding machine componentsPolishingBrush

The invention relates to the technical field of industrial brushes, and discloses an industrial polishing brush for plate processing. The industrial polishing brush comprises a brush plate and adaptive grooves formed in the ground of the brush plate; the adaptive grooves are uniformly distributed in a circumferential shape, and adjusting assemblies are arranged in the adaptive grooves; a mountingmechanism is arranged in the middle of the brush plate, the brush plate rotates at a high speed to drive brush wires to polish a metal plate surface, so that when the brush wires located at the bottomof an adjusting block abut against a protruding block part, an adaptive spring is driven to contract due to the action of extrusion force, namely the adjusting block is driven to move upwards till the brush wires located at the bottom of the adjusting block are attached to the protruding block, and the brush plate rotates at a high speed to polish the metal plate surface; and after polishing of the protruding block part is completed, the adaptive spring releases elastic acting force along with reduction of the protruding block, the adjusting block is slowly driven to move downwards till polishing of the protruding block is completed, namely, the brush wires located at the bottom of the adjusting block are flush with the brush wires located at the bottom of the brush plate, more uniform polishing operation is conducted, and the polishing effect on the metal plate surface is improved.

Owner:安徽省潜山县天柱刷业有限公司

Packaging robot for tea packaging and tea packaging method

InactiveCN112896675AIncrease contact areaEasy to installSievingDrying solid materials with heatProcess engineeringMechanical engineering

The invention discloses a packaging robot for tea packaging. The packaging robot for tea packaging comprises a fixed base, a packaging bottom plate, a packaging outer shell, a heat preservation plate, eddy current heating mechanisms, an induced draft fan, a filter screen mechanism and a pressing and packaging mechanism, and the packaging bottom plate is fixedly installed at the center position of the upper surface of the fixed base through fixing bolts; and the packaging outer shell is fixedly installed on the upper surface of the packaging bottom plate through fixing bolts, the heat preservation plate is fixedly installed on the upper portion of the inner wall of the packaging outer shell through fixing bolts, the eddy current heating mechanisms are fixedly installed on the two sides of the lower portion of the heat preservation plate, and a drying cylinder is arranged between the two eddy current heating mechanisms and is of a hollowed-out structure. When the packaging robot for tea packaging is used, the drying work before tea packaging can be conveniently completed through the electromagnetic eddy current effect, energy saving and environmental protection are achieved, the purposes of automatic tea screening work, subsequent tea packaging quality improvement and classified storage and sales can be achieved, the using performance is good, the structure is simple, the layout is reasonable, and the packaging robot is suitable for popularization and use.

Owner:南京迪海智科精密机械有限公司

Self-cleaning device for environmental dust removal and deslagging

PendingCN114432803AReduce the difficulty of using the flow rateImprove efficiencyGas treatmentDispersed particle filtrationDust controlEnvironmental engineering

The self-cleaning device comprises an air inlet pipe and an air outlet pipe, a cavity is formed in the lower end of the air outlet pipe, the lower end of the air outlet pipe communicates with the air inlet pipe through a bent pipe, a third slag discharging opening is formed in the bottom of the bent pipe, and a filtering part is arranged on the cavity; the filter part comprises at least one filter screen flashboard, the filter screen flashboard is inserted into the cavity, the filter screen flashboard is in sliding connection with the cavity in the radial direction of the cavity, and at least one filter screen is arranged on the filter screen flashboard. Meanwhile, the two filter screens are arranged on the filter screen flashboard and can work in sequence, so that the filter screens cannot be replaced and cleaned without shutdown, the flow speed is reduced, the use difficulty is reduced, and the use efficiency is improved.

Owner:HEFEI FOUND TECH

Wide-angle lens assembly of external wing mirror of pickup truck

The invention discloses a wide-angle lens assembly of an external wing mirror of a pickup truck. The assembly comprises a wing mirror housing, an upper rear viewing lens and a lower rear viewing lensare embedded in the external wing mirror housing, the combination of flat and curved surfaces is adopted by the upper rear viewing lens to ensure that a rear side visual field is smooth while the upper rear viewing lens can be extended towards the rear outer side as much as possible, the lower rear viewing lens matching with a curved surface is capable of providing part of the lower side visual field of the vehicle while multiple visual angles are ensured to greatly improve the completeness of the rear side visual field, an air blowing channel is formed while a rain blocking shelter is arranged so that adhering liquid (rain water, snow water and the like) can be effectively blown away, an electric heating film is matched with the assembly, water, frost and fog can be effectively resisted,and the using safety is higher.

Owner:JIANGSU KAWEI AUTOMOBILE IND GRP CO LTD

Automatic construction waste removing environmental protection device and using method thereof

The invention discloses an automatic construction waste removing environmental protection device and a using method thereof. The automatic construction waste removing environmental protection device comprises a cleaning device and a collecting device, the cleaning device comprises two rotating frames, each rotating frame comprises two supporting rods which are provided with supporting circular plates, and a rotating roller is arranged between every two corresponding supporting circular plates; a cleaning drum is installed between every two corresponding rotating rollers; each cleaning drum isinternally provided with an air blowing device, a twisting device and a rotating device in sequence; the collecting device is arranged below a plurality of leaking holes, the collecting device includes four collecting rods, a collecting frame is installed on the collecting rods, a collecting drum is arranged at the bottom of the collecting frame, and a vibration device is further arranged at the bottom of the collection frame. The automatic construction waste removing environmental protection device is simple in use, construction waste is effectively collected, and air pollution caused by finedust particles can be prevented.

Owner:陈绪涛

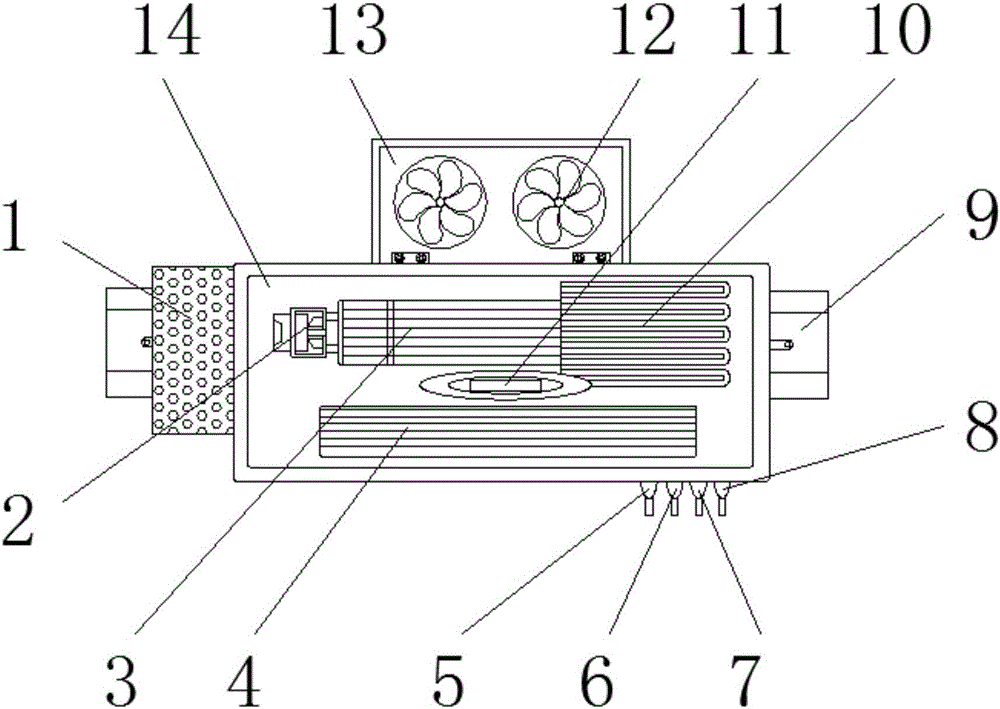

Air conditioner capable of generating steam in self-supporting mode and achieving ventilation and special for constant-temperature warehouse

InactiveCN106288099AEffective blowingBlow off promotionMechanical apparatusSpace heating and ventilation safety systemsWater vaporFood storage

The invention discloses an air conditioner capable of generating steam in a self-supporting mode and achieving ventilation and special for a constant-temperature warehouse. The air conditioner comprises a wind wheel, a high temperature pipe, a fan support plate and an air conditioner body, the bottom of the air conditioner body is provided with a cold circulation pipe, the portion, close to the right side of the cold circulation pipe, of the bottom of the air conditioner body is provided with a thermal circulation pipe, the high temperature pipe is installed on the portion, close to the right side of the thermal circulation pipe, of the bottom of the air conditioner body, and the portion, close to the right side of the high temperature pipe, of the bottom of the air conditioner body is provided with a return pipe. According to the air conditioner capable of generating the steam in the self-supporting mode and achieving ventilation and special for the constant-temperature warehouse, after a steam generator is used, the interior of a food storage warehouse can be subjected to humidification treatment, and the quality of food cannot be affected due to dryness in the room; after the fan for ventilation is used, blowing can be conducted on the interior of the warehouse, steam generated by the steam generator can be effectively blown out, ventilation can be conducted on the interior of the warehouse, and emission of undesirable odor generated by the fact that the food varieties are promiscuous is promoted.

Owner:SHENZHEN WOHAISEN TECH CO LTD

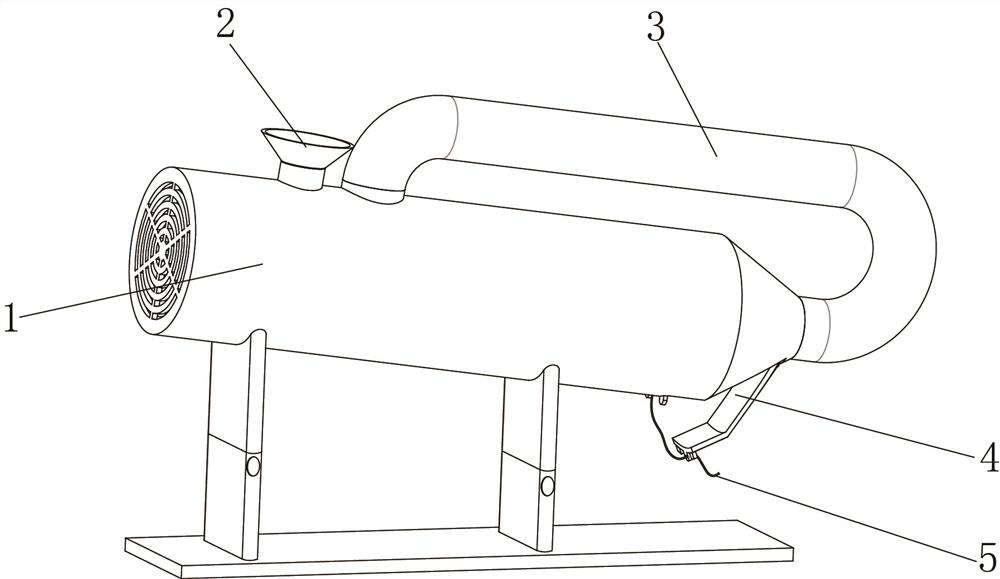

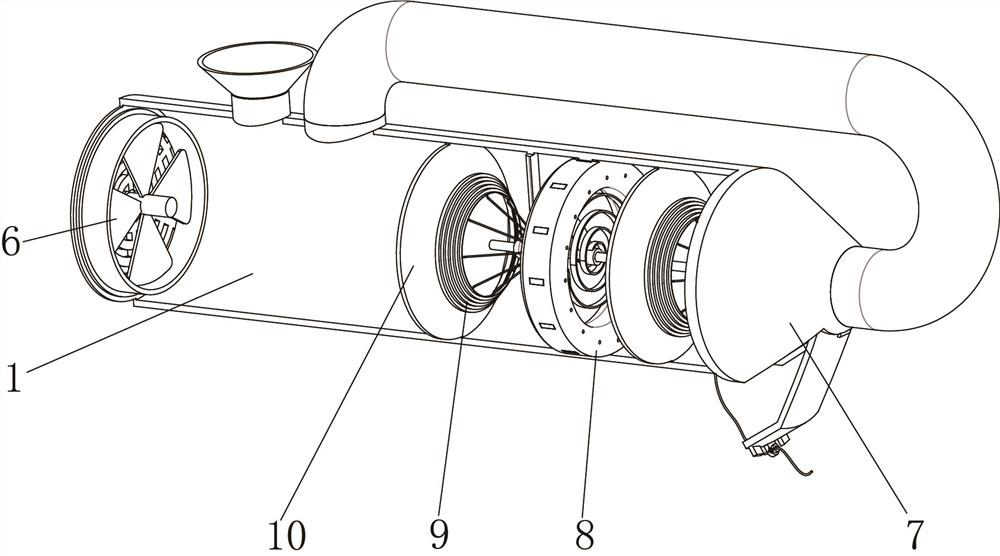

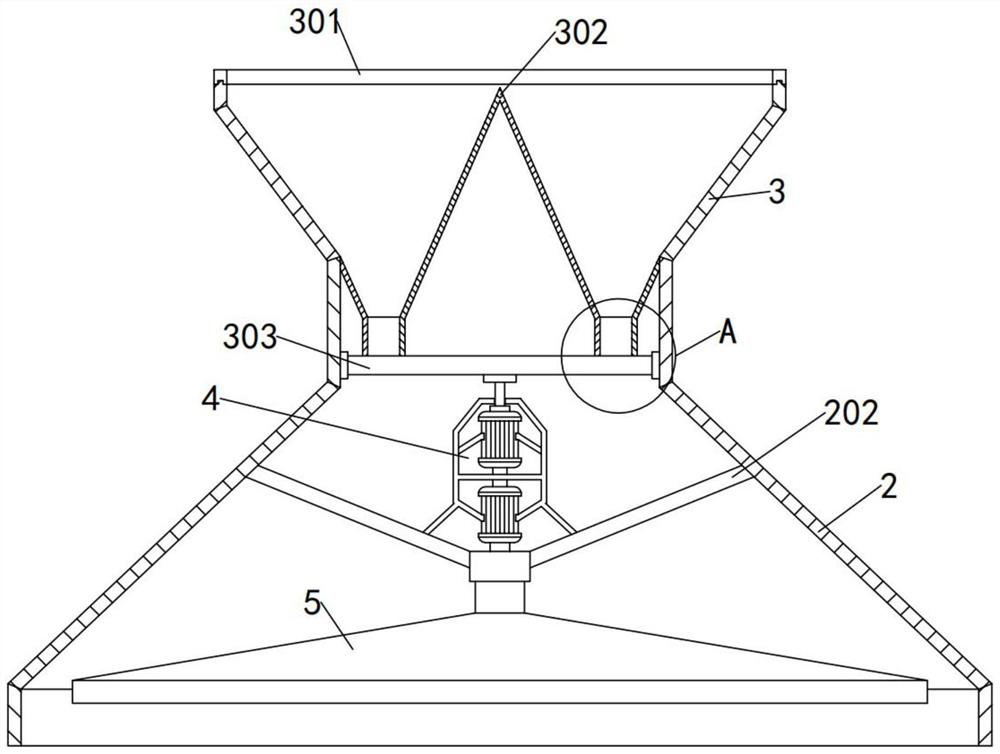

A hot air internal circulation type tea-milling stove and drying method thereof

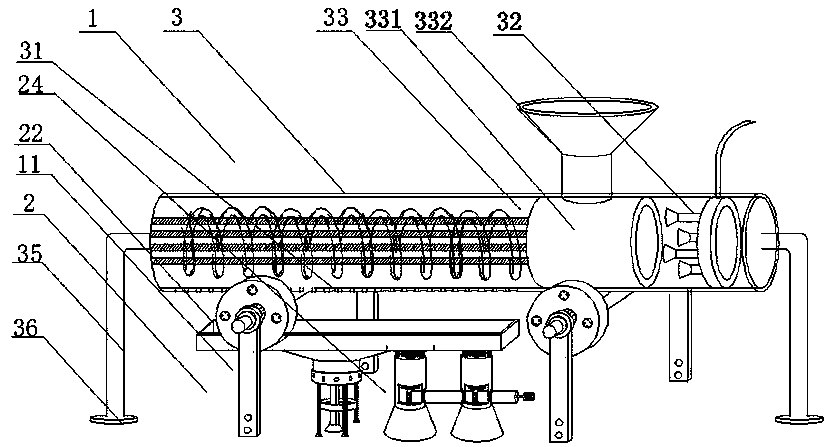

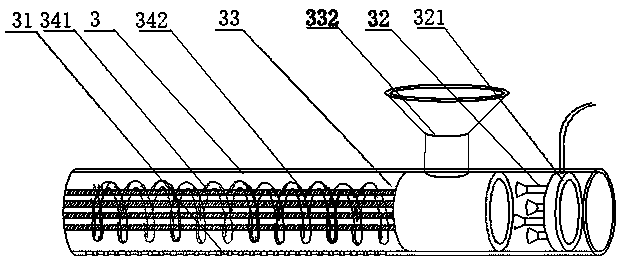

ActiveCN112595045BAchieve diffusionFully contactedTea dryingDrying gas arrangementsEngineeringHot blast

The invention discloses a hot air internal circulation type tea-milling furnace and a drying method thereof, and relates to the technical field of tea-milling drying; in order to improve the drying effect; the tea-milling furnace includes a furnace body, and an adjustable support is arranged at the bottom of the furnace body One end of the furnace body is integrated with a gathering hopper, the outer wall of the bottom of the gathering hopper is connected with a discharge door through a hinge, the inner wall of one end of the furnace body is installed with a drying fan through the fan seat, and the whole furnace body is inclined; The dry method includes the following steps: adjusting the inclination angle of the furnace body; and adjusting the effective length of the elastic rope through a fixing knob. In the present invention, structures such as a confluence plate and an elastic wrinkle ring are arranged, and the whole furnace body is arranged at an inclination, so that the milled tea is constantly approaching the discharge door under the conveyance of hot air and its own gravity, and multiple confluence plates and elastic wrinkle rings can achieve convergence. The wind force and the purpose of grinding the tea make the outer surface of the grinding tea fully in contact with the hot air to ensure the drying effect.

Owner:WUYI HUASHUAI TEA SEEDS MACHINERY CO LTD

Folding separate machine of non-woven tablecloth

InactiveCN107902181AEffective blowingImprove cooling effectPackaging machinesInterference fitDrive shaft

The invention discloses a folding separate machine of non-woven tablecloth. The folding separate machine structurally comprises an adjusting head, a working head, a working plate, a support, a cushionplate, a fan heating device, a separation plate, a supporting plate and a motor box. The outer ring of the right side of the adjusting head is movably connected with a through hole formed in the surface of the left side of the motor box by adopting an interference fit mode, and firmly attached through a tight necklet. The folding separate machine of the non-woven tablecloth is provided with the fan heating device, firstly the equipment is fixed through mutual embedment of the bottom end of the supporting plate and a clamping groove formed in external equipment, then a transmission rod transmits power, fan blades are arranged on the outer ring of a rotating bearing and can rotate clockwise when power is applied to the fan blades, because the fan blades are connected with the rotating bearing, the rotation performance is high, heat energy can be effectively blown away to a heat dissipation hole, finally the heat dissipation hole emits the heat energy for special usage, accordingly the heat dissipation property of the equipment is improved, and the situation that the equipment burns out a circuit board so that the equipment cannot work normally is prevented.

Owner:仪征市振威无纺制品有限公司

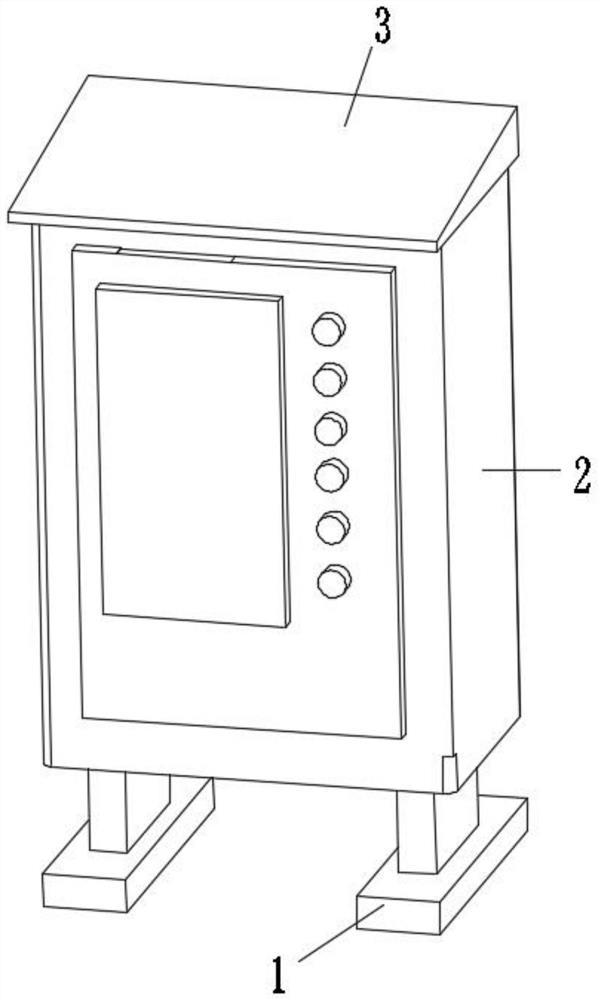

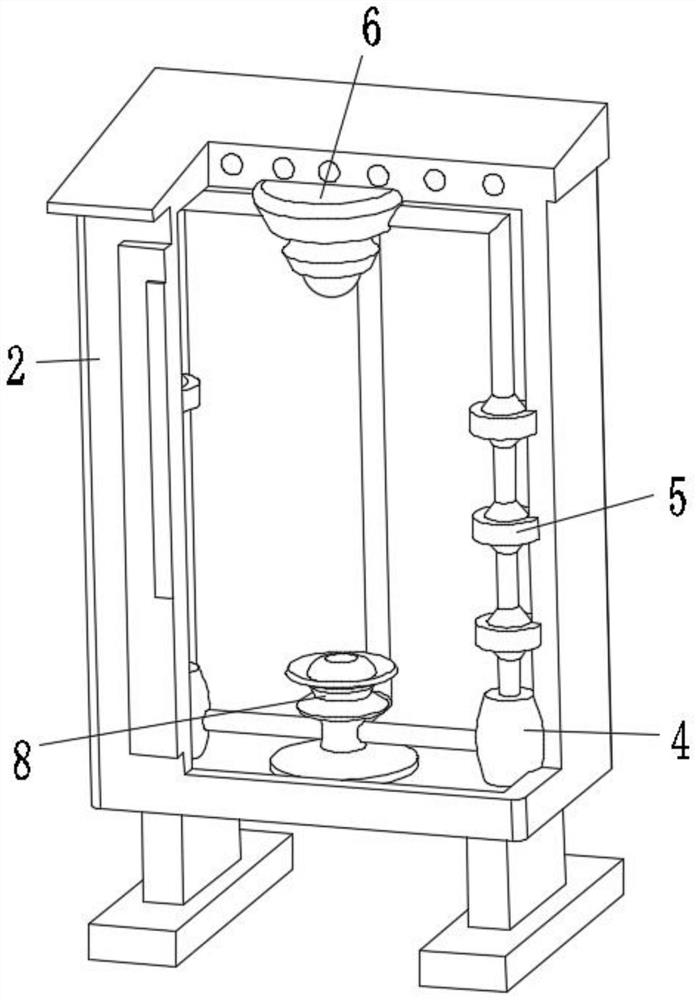

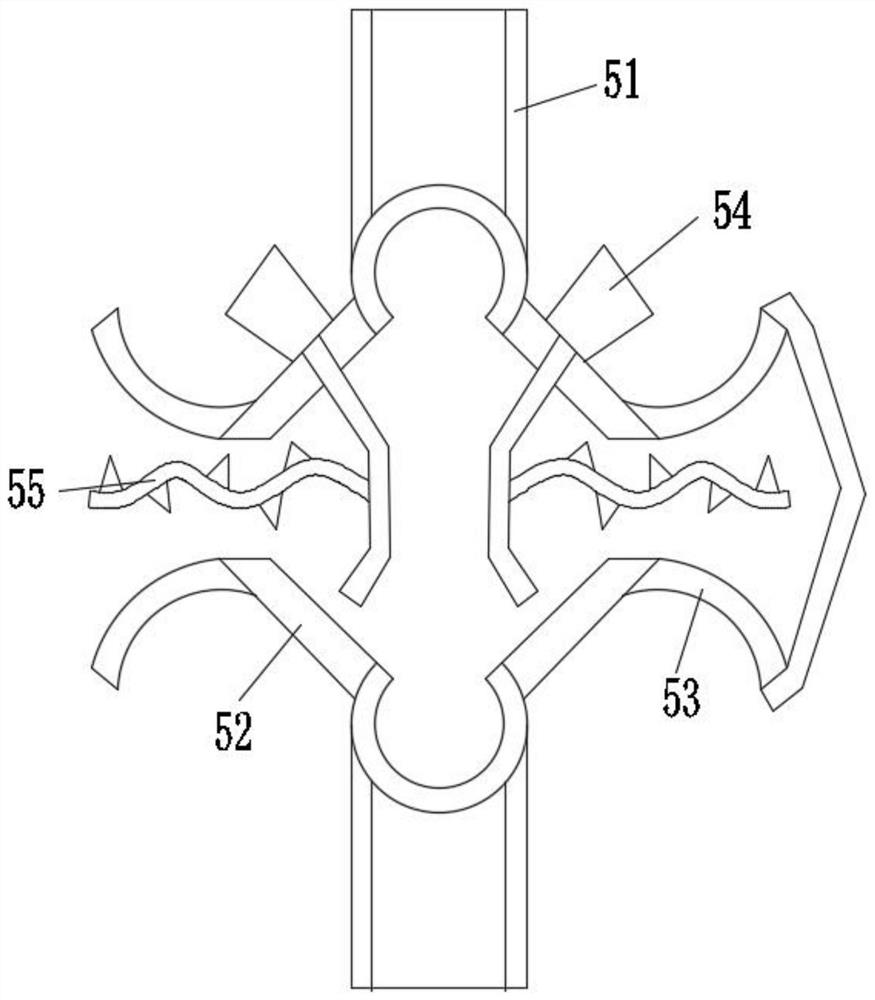

Self-adaptive emergency processing power supply cabinet

PendingCN113904223AHow to removeEffective adsorption and coolingSubstation/switching arrangement cooling/ventilationFire rescueSelf adaptiveEmergency treatment

The invention discloses a self-adaptive emergency treatment power supply cabinet, and relates to the technical field of power supply machinery, the self-adaptive emergency treatment power supply cabinet structurally comprises a base, the top of the base is fixedly connected with a cabinet body, the top of the cabinet body is fixedly connected with an inclined top, and the bottom of the inner side surface of the cabinet body is fixedly connected with a dust falling mechanism; a dry powder tank is fixedly connected to the lower position of the inner side face of the cabinet body, a spraying mechanism is fixedly connected to the top of the dry powder tank, a regulation and control mechanism is fixedly connected to the top of the inner side face of the cabinet body, and the side face position of the regulation and control mechanism is fixedly connected with the top of the spraying mechanism. According to the self-adaptive emergency treatment power supply cabinet, through cooperative use of the spraying mechanism, the regulation and control mechanism, the anti-explosion mechanism, the dust falling mechanism and other mechanisms, the problems of how to automatically detect open fire and effectively control a fire source, how to effectively adsorb and cool inflammable and explosive gas and how to effectively remove dust deposited on the electrical element so as to improve the insulating property of the electrical element are solved.

Owner:唐锟

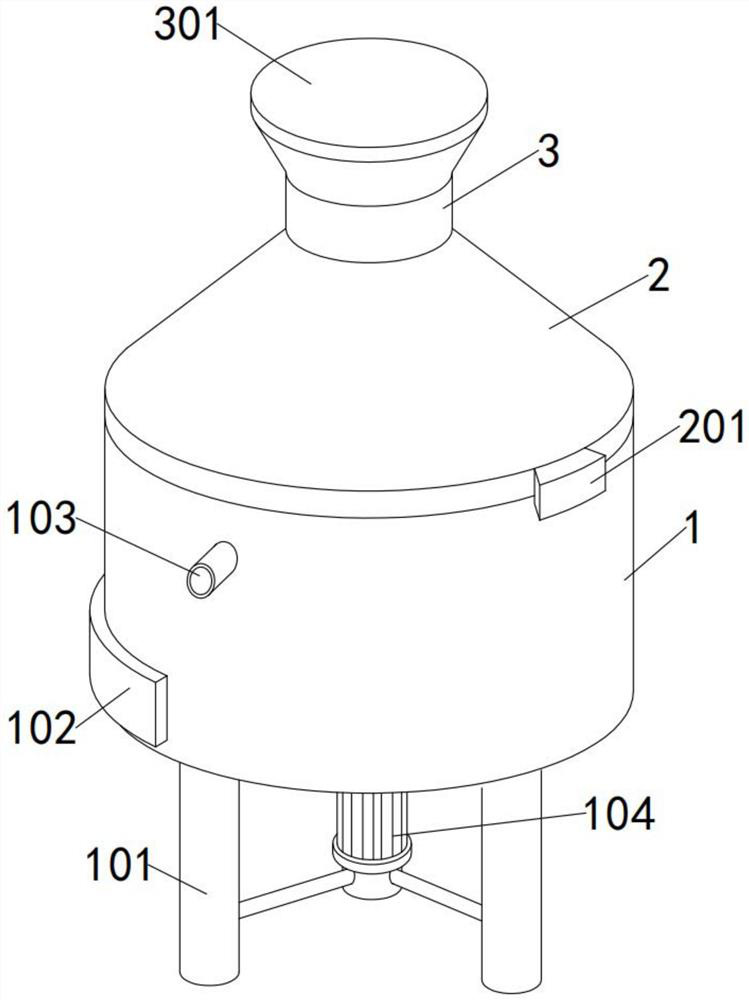

Stirring device for cement-based composite shielding material

PendingCN113815117AImprove the mixing effectPrevents the problem of not being able to mix completely evenlyDispersed particle filtrationCement mixing apparatusManufacturing engineeringCement Material

The invention provides a stirring device for a cement-based composite shielding material, and belongs to the technical field of cement-based materials, a top cover is arranged above a stirring barrel, supporting legs are fixedly connected to the bottom of the stirring barrel, a discharging plate is movably connected to the bottom of the side face of the stirring barrel, a water inlet pipe is embedded into the side face of the stirring barrel, and a rotating shaft is rotationally connected into the stirring barrel. The stirring device for the cement-based composite shielding material is provided with a rotary distribution plate and a flow guide rotating disc, and when the rotary distribution plate and the flow guide rotating disc start to rotate, an electromagnetic shielding material can quantitatively penetrate through a passing pipe and downwards fall to the upper portion of the flow guide rotating disc; by matching with the rotating flow guide rotating disc, the electromagnetic shielding material on the upper portion of the flow guide rotating disc can be uniformly scattered above a stirred cement base and is mixed into the cement base to achieve the purpose of uniform stirring, so that the problem that the electromagnetic shielding material is accumulated in the cement base and cannot be completely and uniformly stirred is effectively prevented; and the mixing effect of the cement base and the electromagnetic shielding material is greatly improved.

Owner:徐州安高新型建材产业技术研究院有限公司

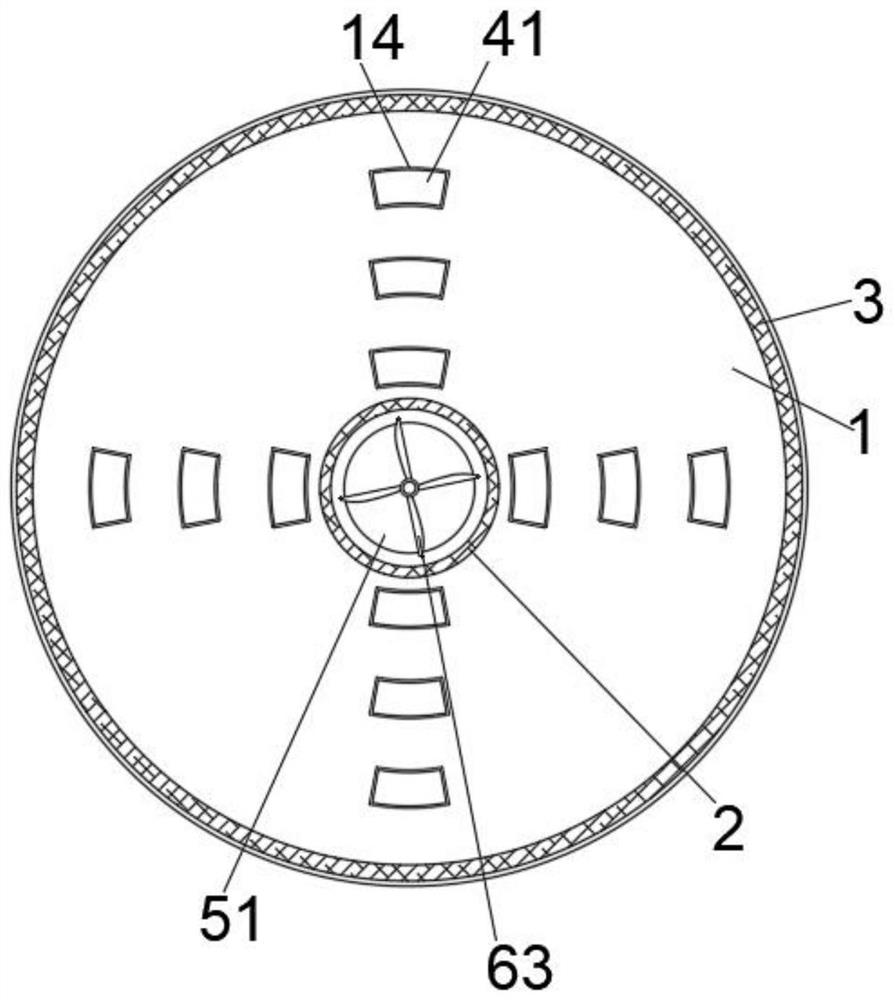

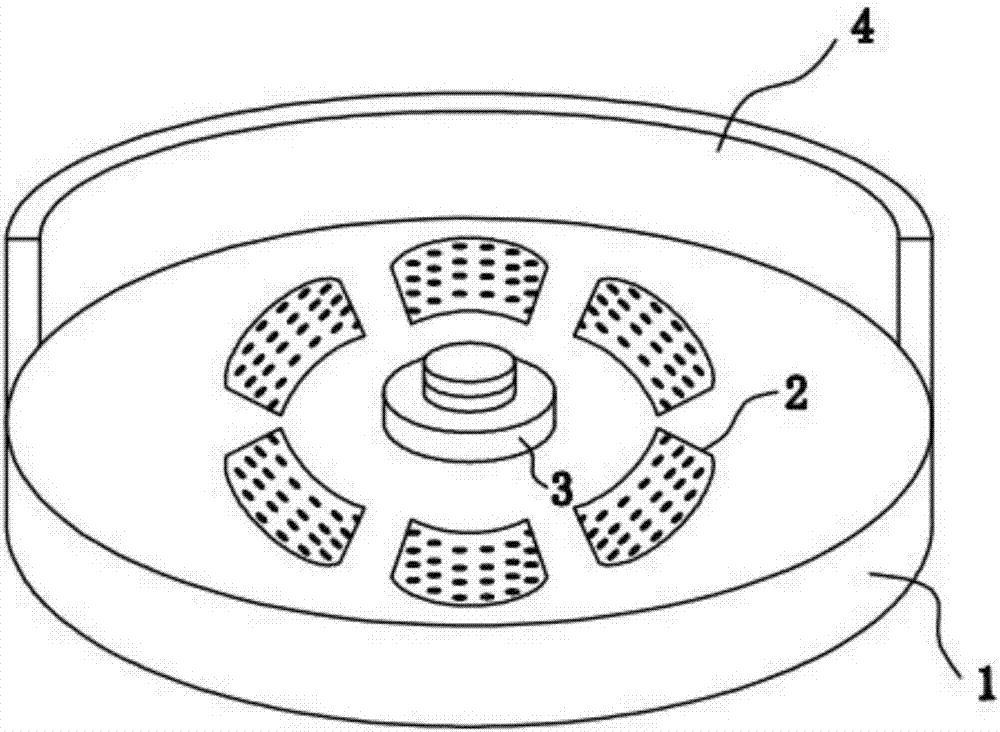

Improved type tablet counting plate device

InactiveCN107352081AIncrease the feeding speedImprove packaging qualityPackagingMechanical engineeringDrug powder

The invention discloses an improved disc counting device in the technical field of pharmaceutical packaging, which includes a turntable. The top of the turntable is evenly opened with six groups of counting holes arranged in a circle around the center of the turntable, and the center of the turntable is also connected to There is a vertically arranged rotating shaft, and a section of arc-shaped baffle is fixedly installed on the outer edge of the turntable. The invention increases the number of holes on the turntable to 6 groups, improves the feeding speed of medicines, improves production efficiency, and saves equipment operation At the same time, through holes for spraying are provided in several grain holes, which can effectively spray the powder on the surface of the tablet and improve the quality of drug packaging.

Owner:湖北金龙药业有限公司

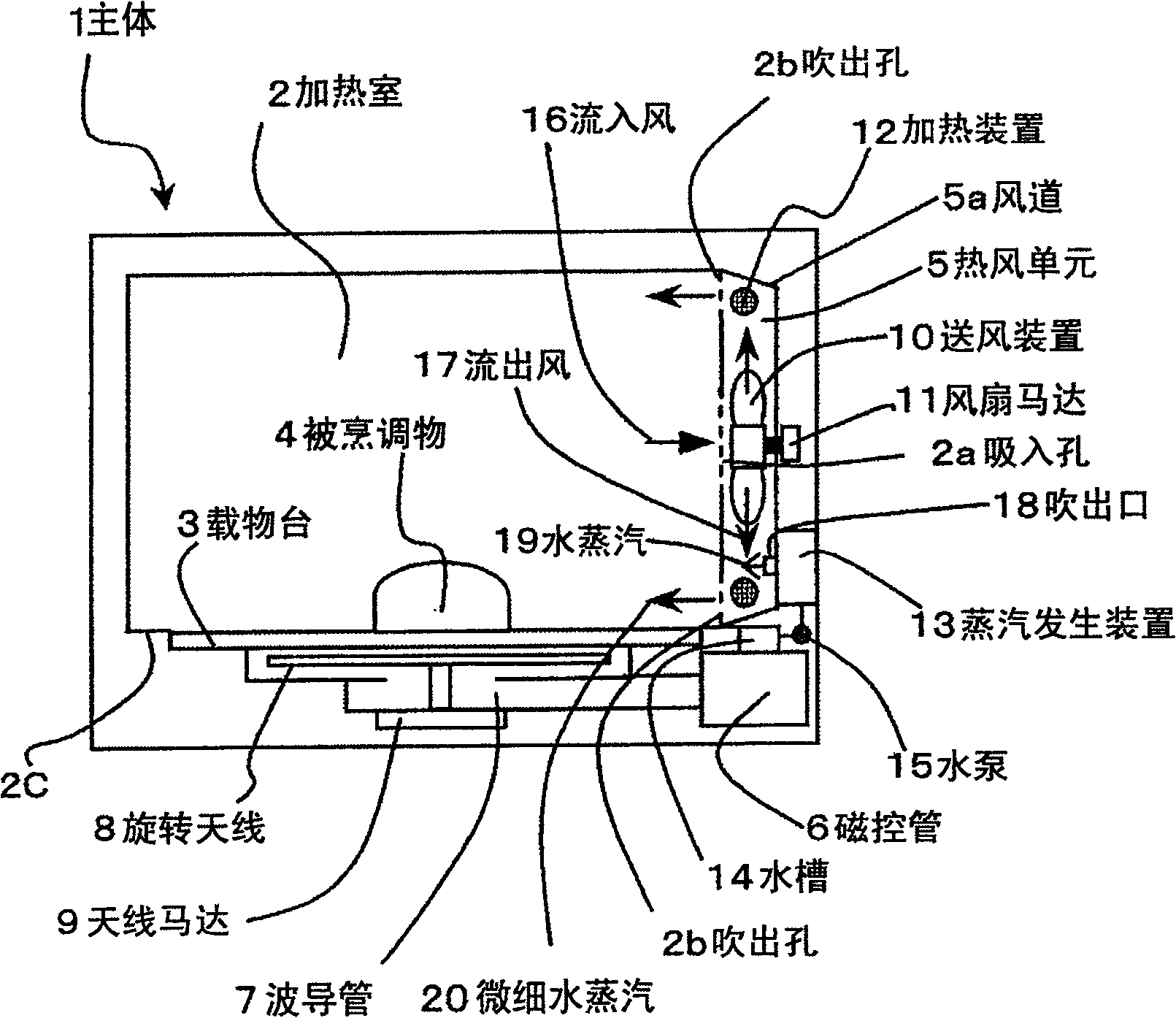

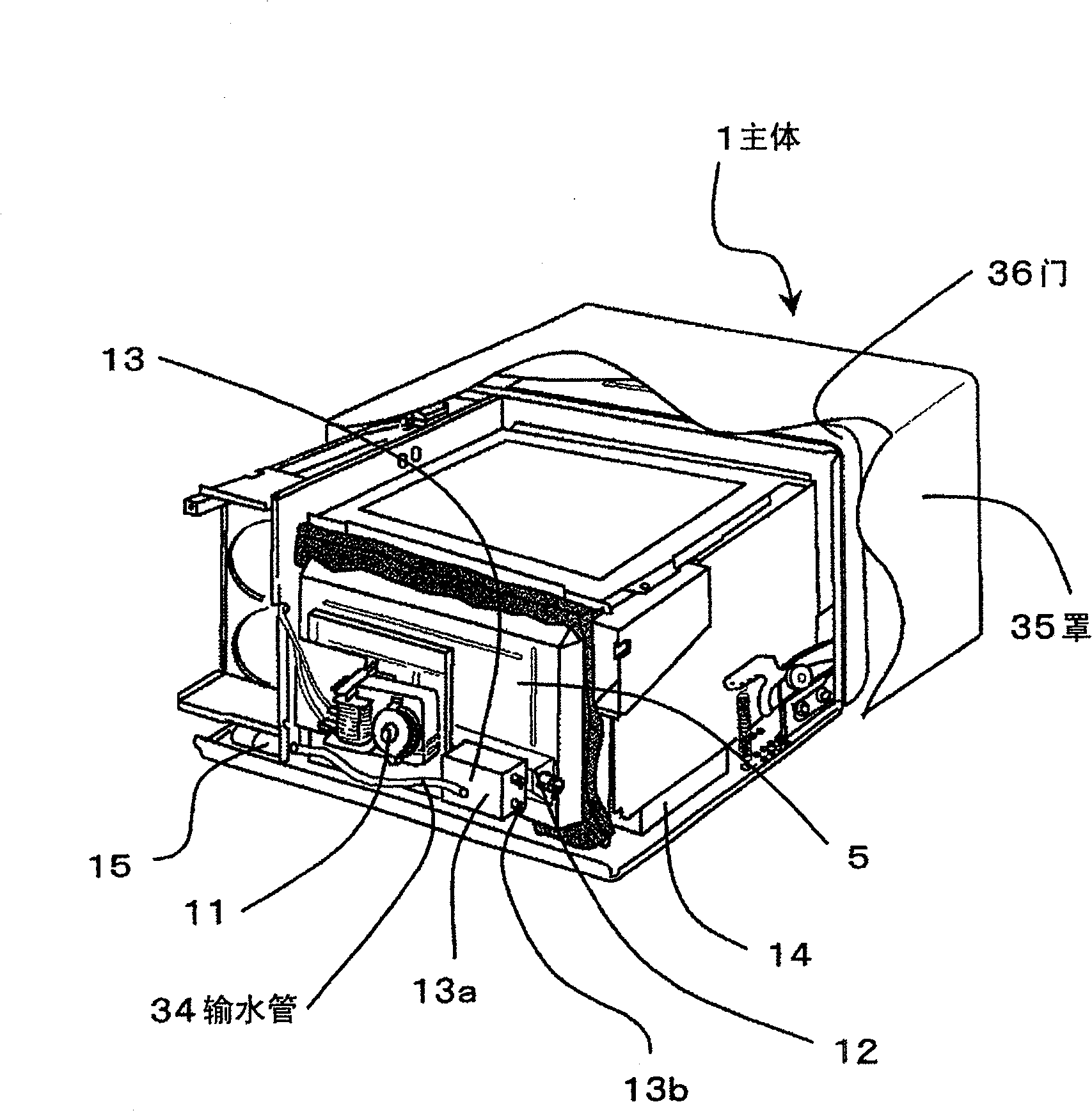

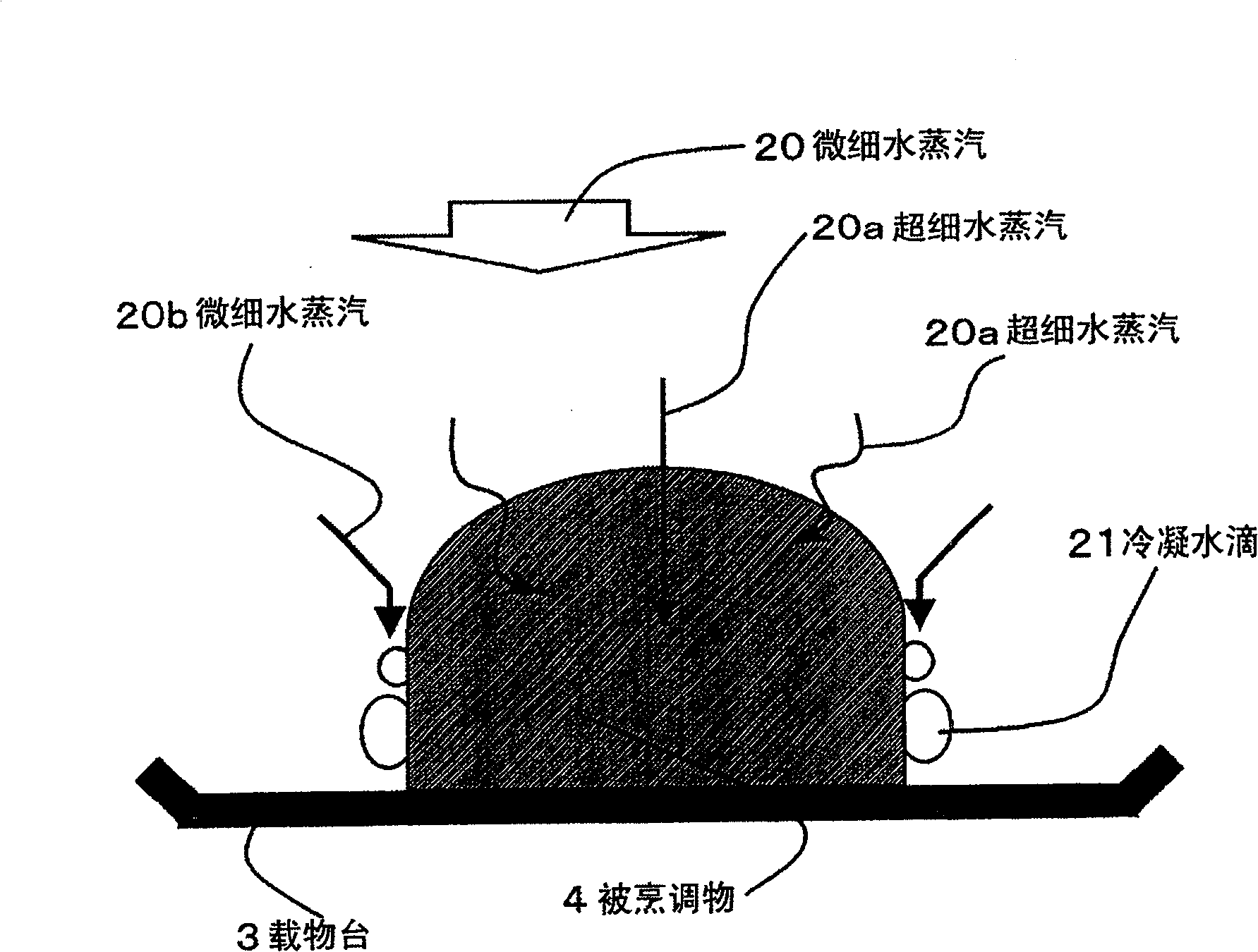

Heating cooker

InactiveCN100534362CMoisturize quicklyEfficient heating and cookingDomestic stoves or rangesLighting and heating apparatusMicrowave ovenWater vapor

The invention provides a heating cooker in a microwave oven or the like which supplies water vapor to the cooked object in the heating chamber and cooks it, which can simultaneously realize rapid moisturizing of the cooked object and high-efficiency heating and cooking of the cooked object, and simply Delicious cooked food can be provided. The heating cooker of the present invention is equipped with: a heating chamber (2) for accommodating the object to be cooked (4), a heating device (12) for heating the heating chamber (2), a steam generating device (13) for generating water vapor, and a water heater The air supply device (10) of the crushing device that gives impact to the steam and pulverizes it into finer; sprays the water vapor supplied from the steam generating device (13) to the outflow air (17) flowing from the air supply device (10) Blow, because of its impact, the water vapor is pulverized into finer pieces, and the fine water vapor (20) mixed with the outflow wind (17) is supplied into the heating chamber (2) to cook the food to be cooked (4).

Owner:HITACHI HOME & LIFE SOLUTIONS INC

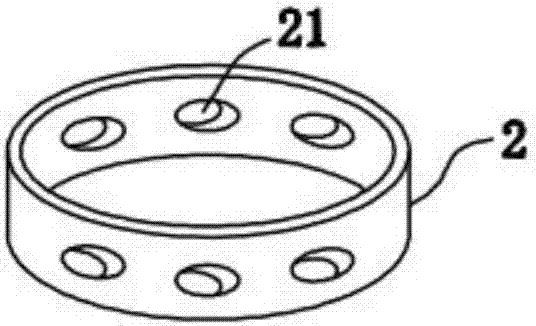

Water conservancy engineering pipeline outer surface rust removal device with positioning performance

InactiveCN112893342AEffective blowingEfficient rust removalHollow article cleaningCircular discSlide plate

The invention discloses a water conservancy engineering pipeline outer surface rust removal device with positioning performance. The device comprises a supporting base, wherein a supporting plate is arranged on one side of the supporting base, a top plate is arranged on the top of the supporting plate, fixing plates are connected to the two ends of the middle of the supporting plate in a clamped mode, and sliding grooves are formed in the outer ends of the same sides of the fixing plates. Sliding plates which are matched with the sliding grooves are arranged in the sliding grooves, symmetrical clamping plates are arranged at the corresponding side ends of the sliding plates at the two ends, a pipeline body is connected between the clamping plates at the two ends in a clamped mode, a plurality of grooves are formed in the corresponding side edges of the fixing plates at the two ends, and roller shafts which are matched with the grooves are inserted into the grooves. Roller wheels are arranged between the roller shafts at the two ends, the roller wheels are located at the bottom of the pipeline body and make contact with the bottom surface of the pipeline body, a hollow through hole is formed in the middle of the supporting plate, a rotating wheel is arranged on the inner wall of the through hole, and a disc is arranged at the end of the side, far away from the supporting plate, of the rotating wheel. The water conservancy engineering pipeline outer surface rust removal device with the positioning performance is convenient to use, small in size and low in cost.

Owner:刘林虎

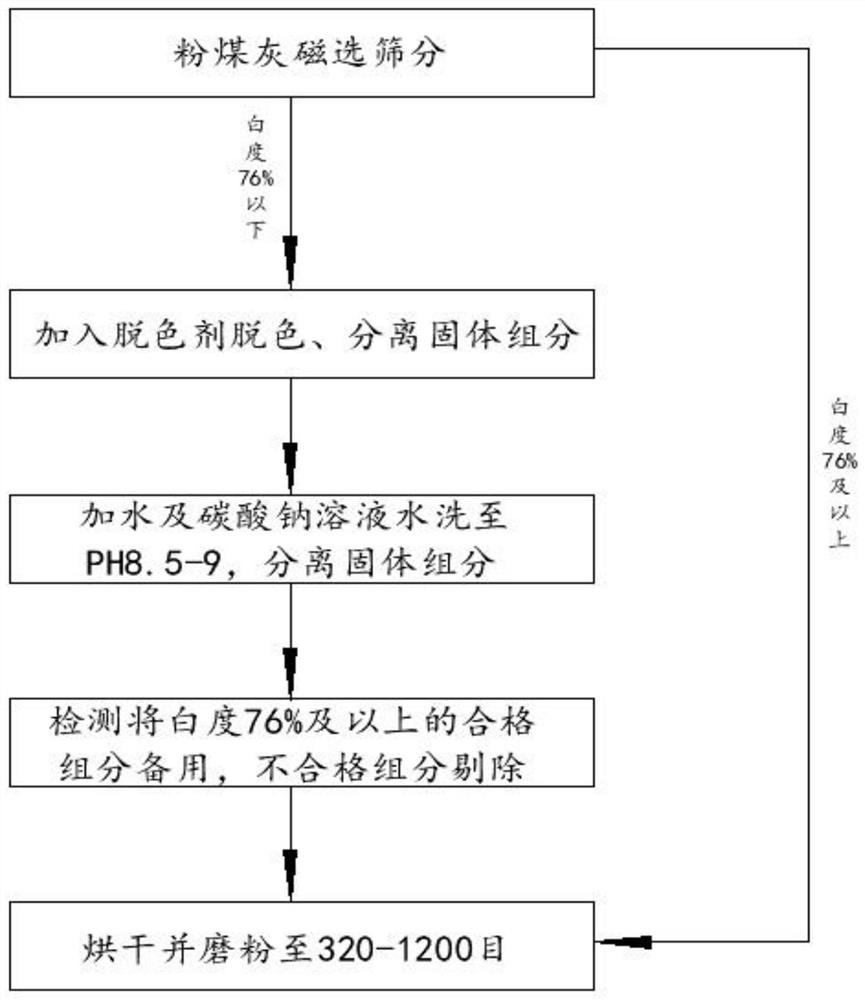

Method for producing putty powder by using fly ash as raw material

PendingCN114031969AReduce manufacturing costLow priceGas current separationFilling pastesIron removalSilicon oxide

The invention discloses a method for producing putty powder by using fly ash as a raw material, which comprises the following steps: feeding fly ash into a vibrating screen with an iron removal facility, after screening, storing qualified components with the whiteness greater than 76% for later use, adding a decolorizing agent into the components which do not meet the requirements, and after stirring and decolorizing, centrifugally separating solid components, adding water into the collected solid components, stirring, adding a sodium carbonate solution for neutralization reaction, collecting the solid components by a centrifugal separation device, and drying and grinding the components with the whiteness greater than or equal to 76%. According to the method, the fly ash is used as a raw material to produce the putty powder, iron and carbon in the fly ash are removed through simple procedures of magnetic separation screening, decoloration, water washing, drying grinding and the like, the content of separated effective solid components including silicon oxide and aluminum oxide reaches 86% or above, the produced product is stable in physical and chemical properties, excellent in quality and environment-friendly in performance, the whole production process is easy to operate, the production efficiency is high, the fly ash is low in price, and the production cost of the putty powder produced by taking the fly ash as the raw material is reduced by 45%-55% compared with putty powder sold in the current market.

Owner:白吉元

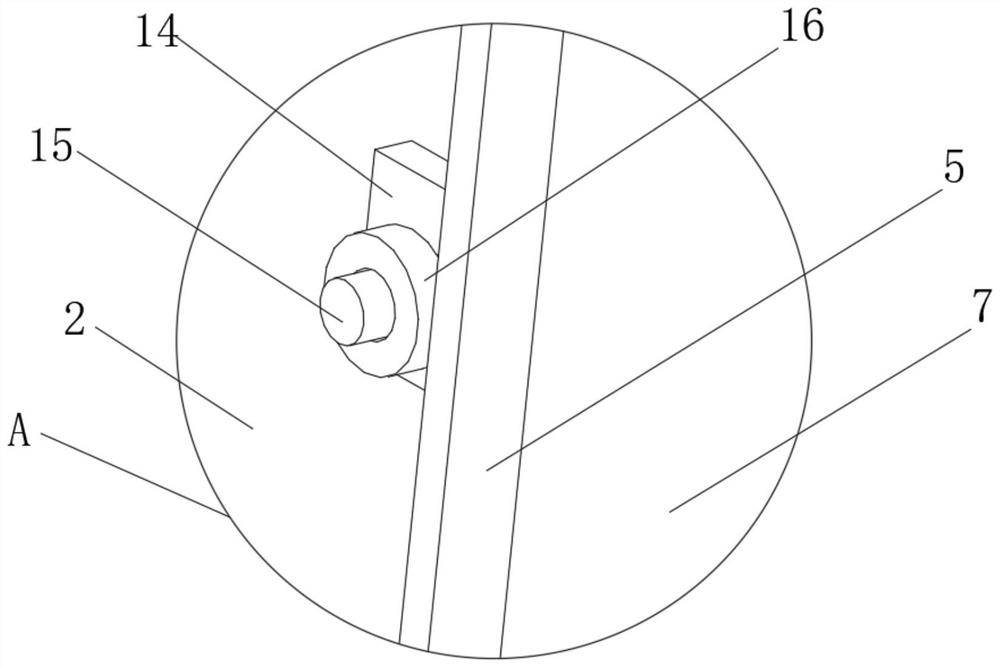

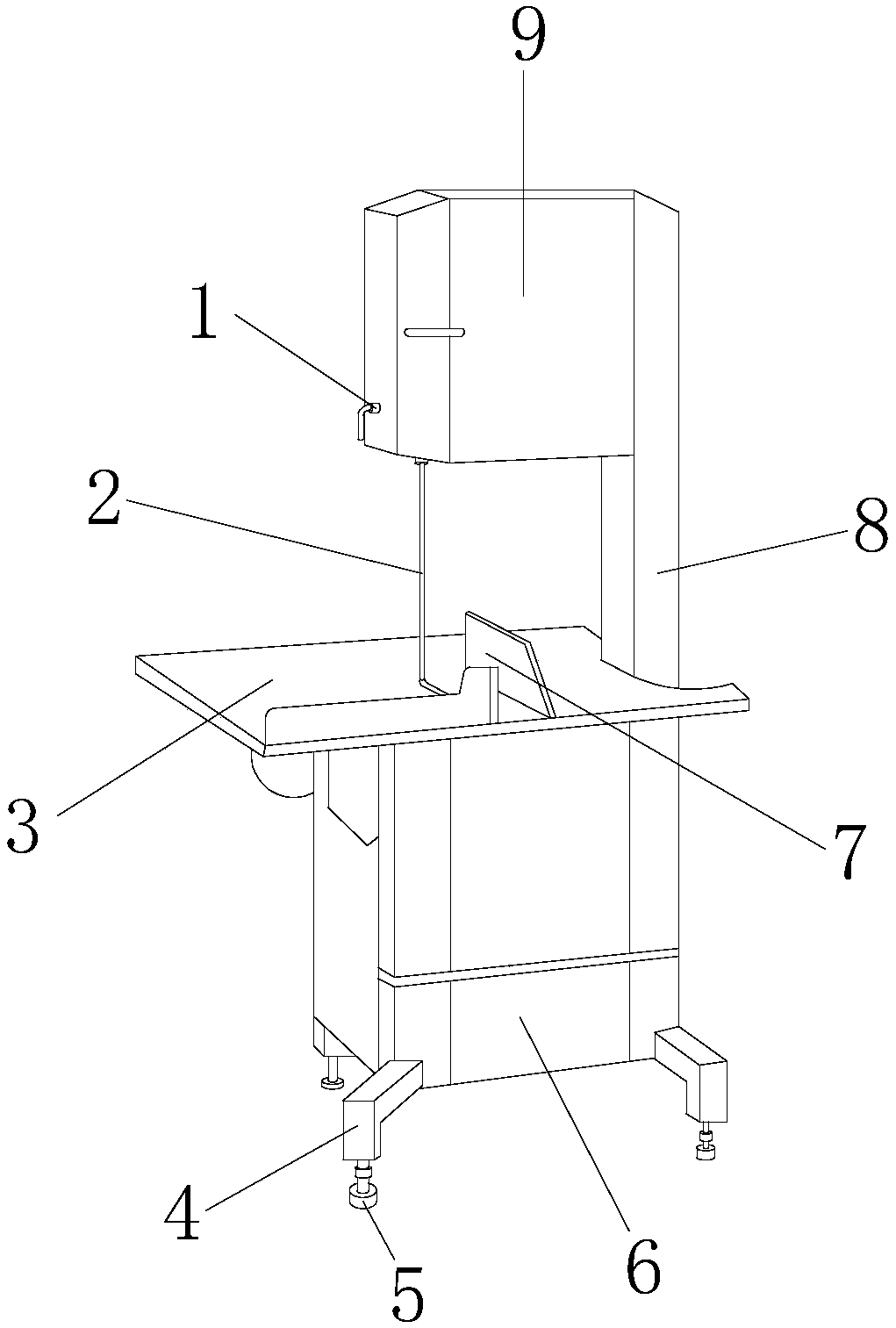

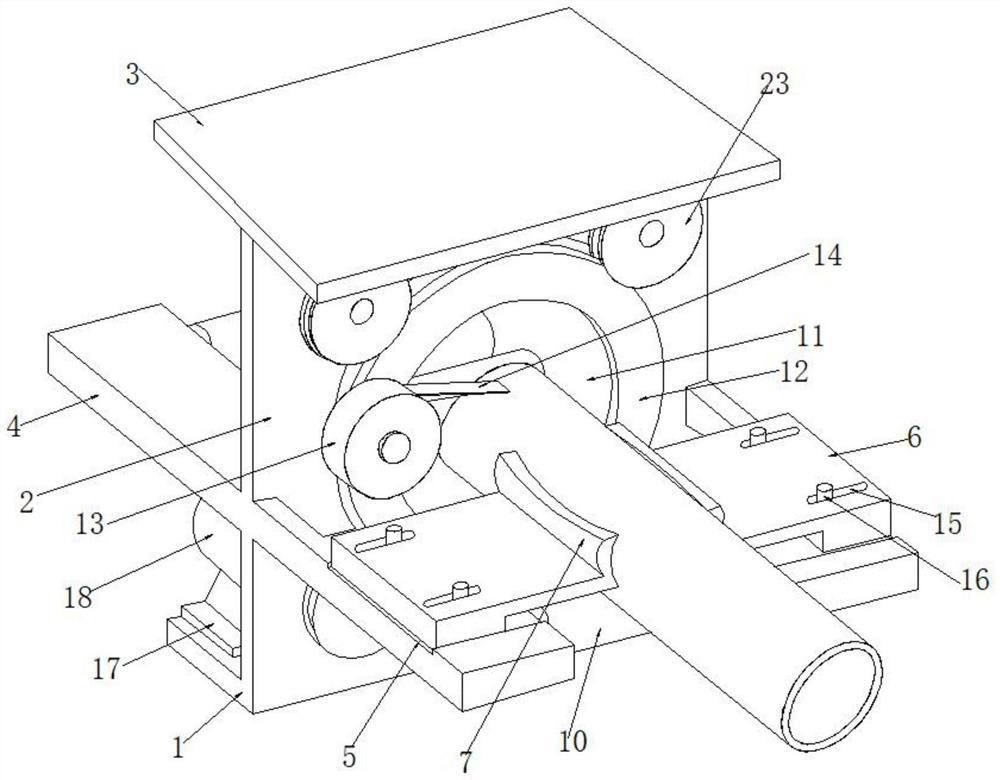

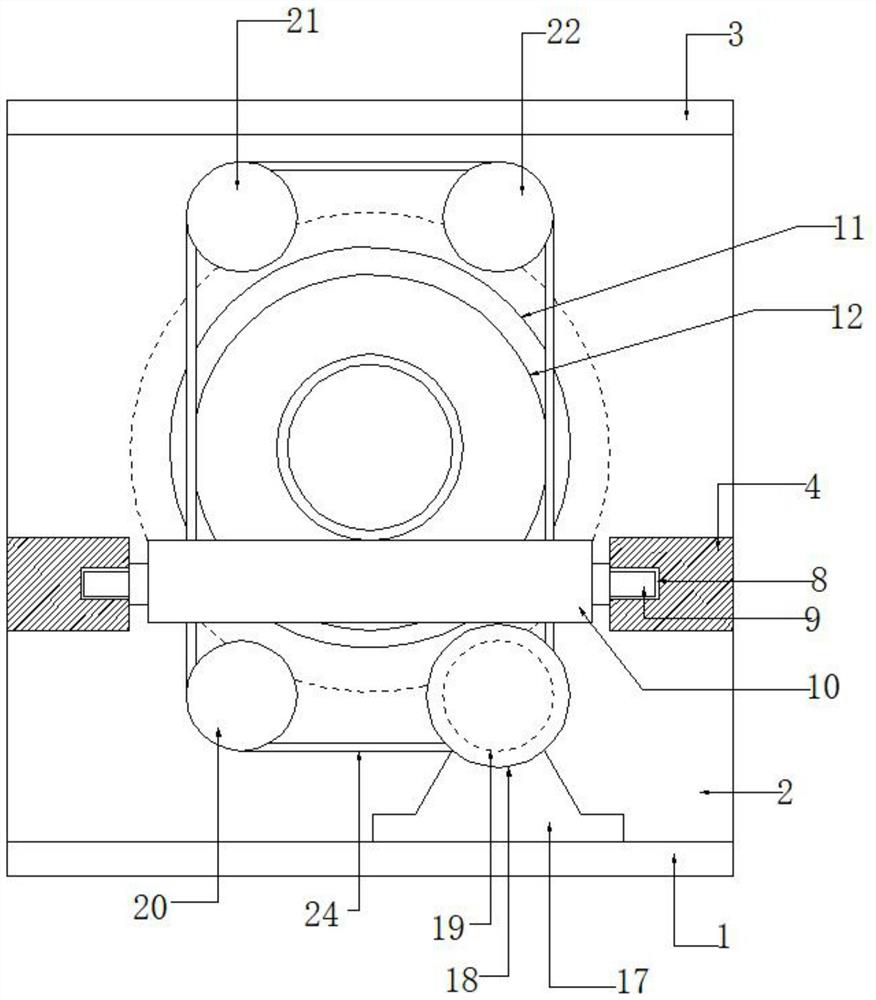

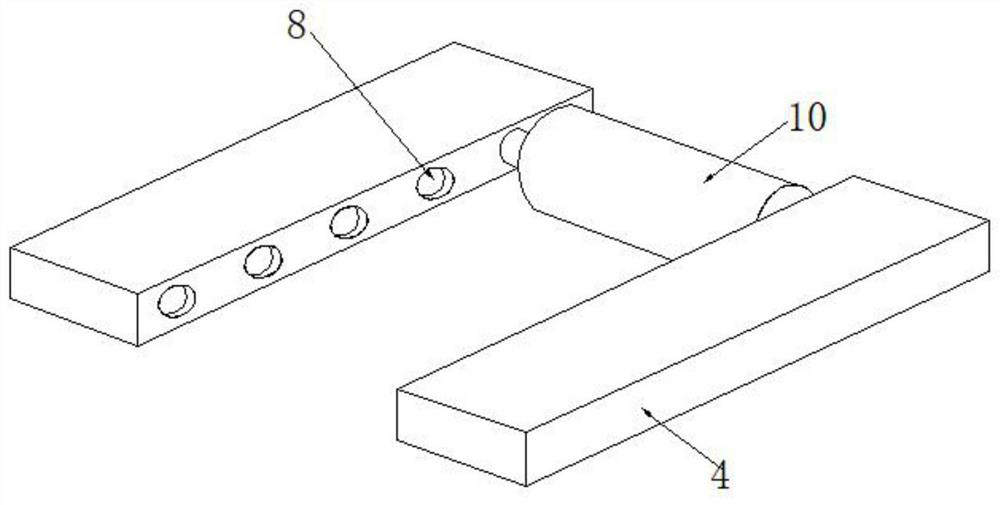

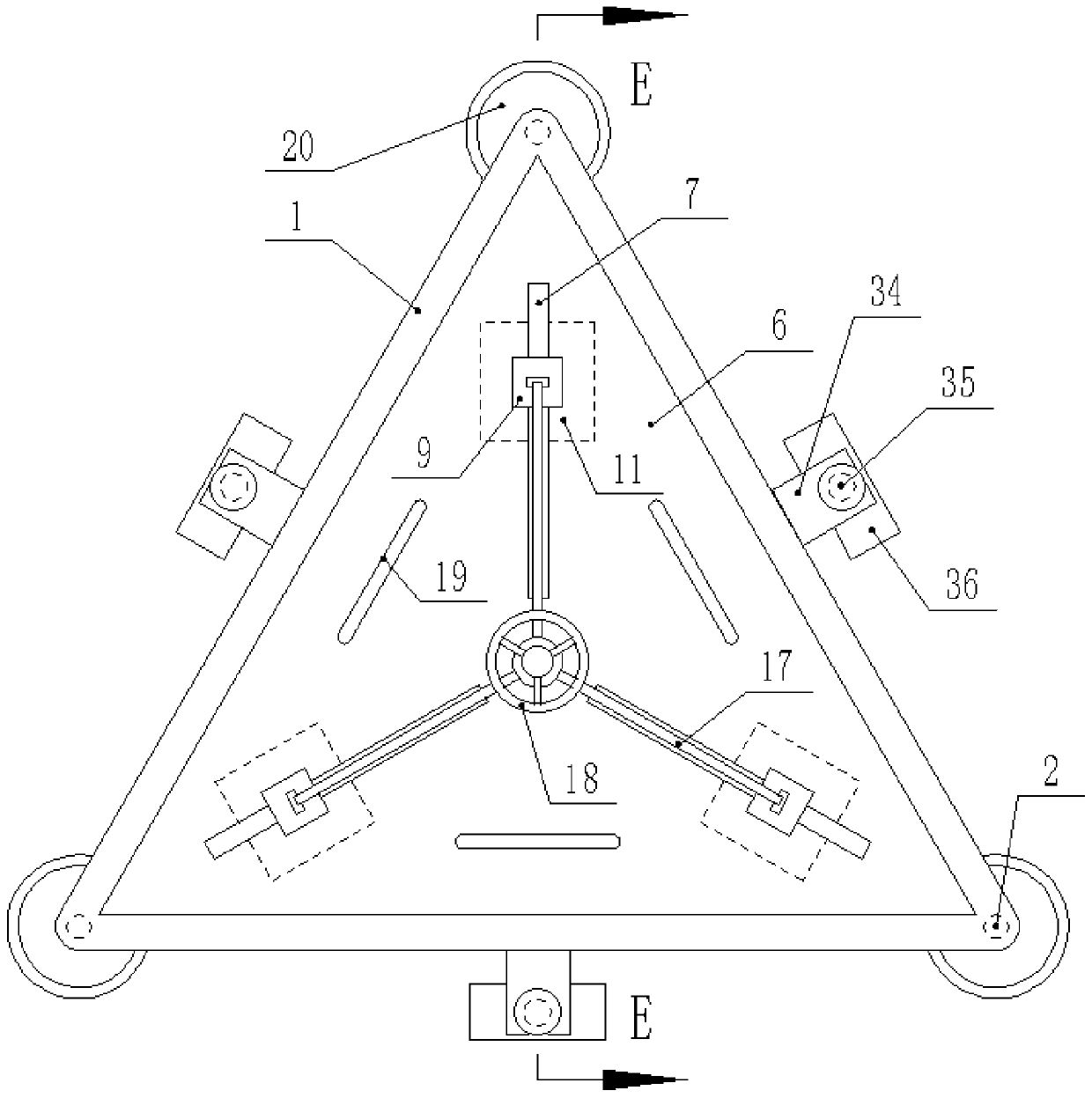

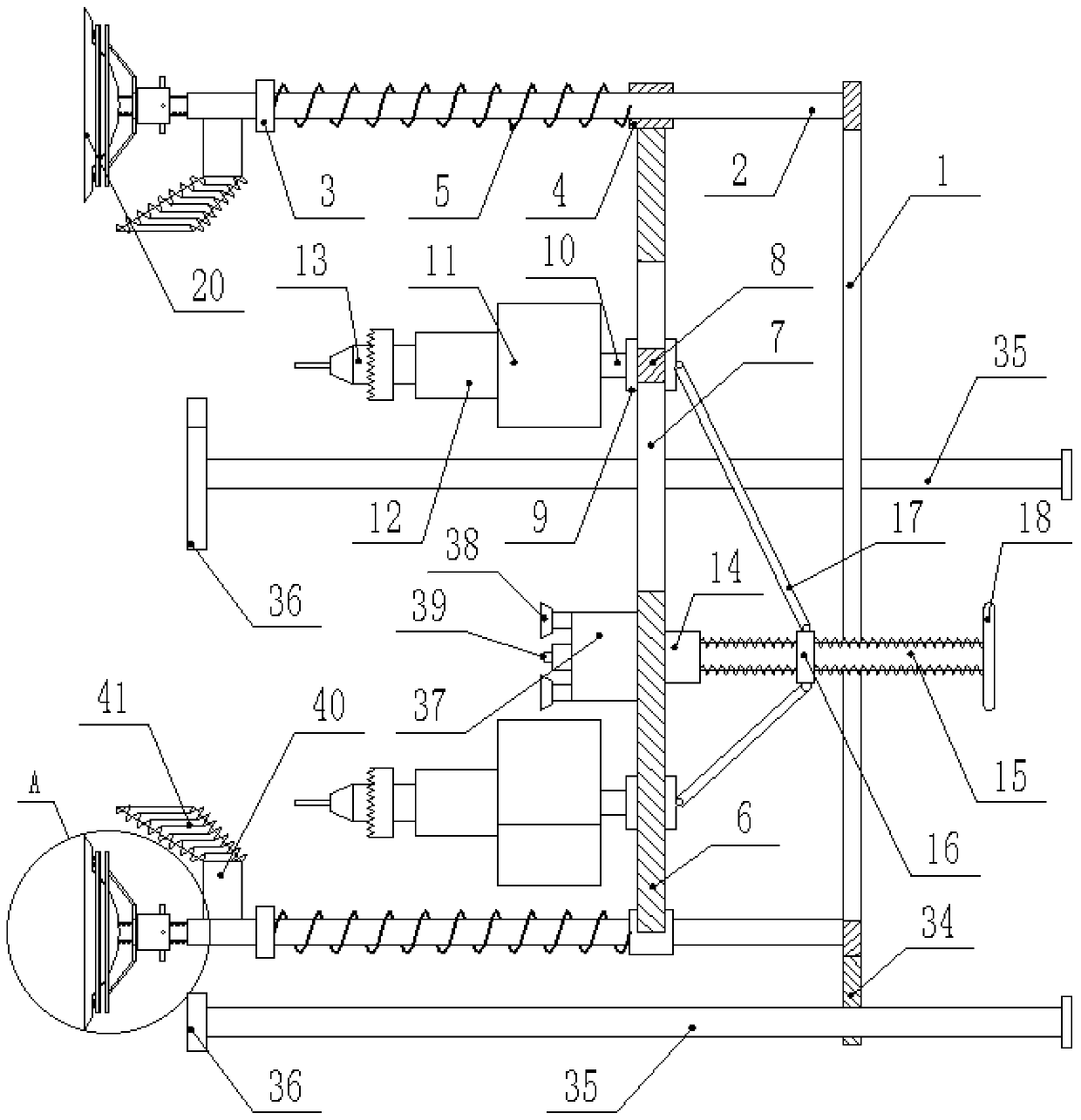

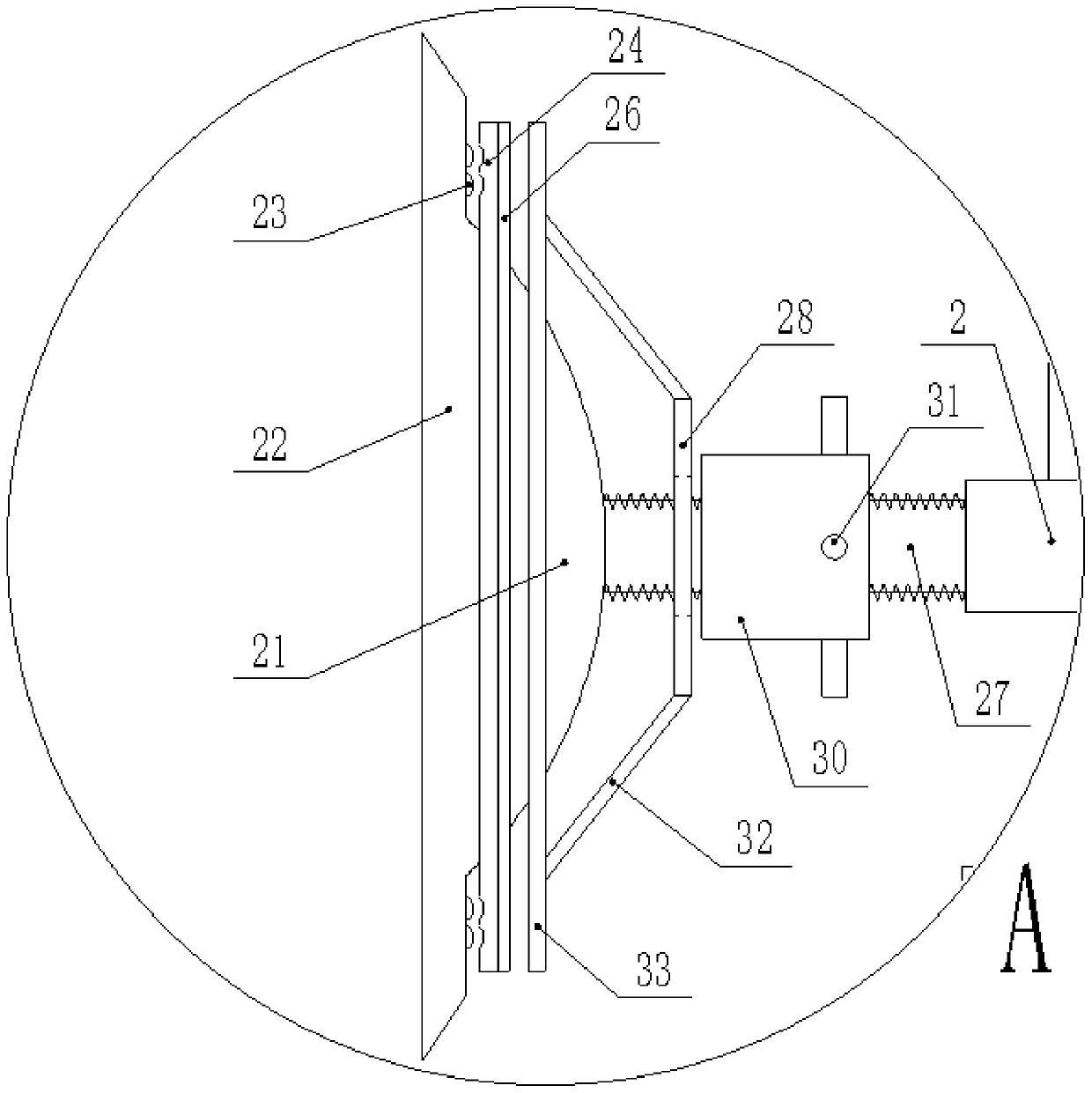

A portable three-hole drilling machine

ActiveCN108655463BEasy to adjustReduce volumeWork benchesPortable drilling machinesClassical mechanicsStructural engineering

The invention discloses a portable three-hole drilling machine. The portable three-hole drilling machine comprises a triangular fixing frame. All corners of the fixing frames are perpendicularly fixedto one ends of fixing rods separately. The other end of each fixing rod is fixedly provided with a suction cup and sleeved with a limiting ring fixedly connected with the fixing rod. The middle of each fixing rod is sleeved with a sleeve slidably connected with the fixing rod. A spring connected to the outer wall of each fixing rod in a sleeving mode is arranged between the corresponding sleeve and the corresponding limiting ring. A fixing plate corresponding to the fixing frame is fixed between the sleeves and is triangular. Three sliding grooves are arrayed at the central position of the fixing plate. Sliding blocks slidably connected with the sliding grooves are arranged in the sliding grooves. Baffles which are attached to the fixing plate are fixed to the upper end and the lower endof each sliding block correspondingly. A fixing block is fixed to the baffle on one side of each sliding block so that the drilling machine can be carried conveniently. The drilling machine is designed to be triangular according to plates where three holes need to be drilled at equal intervals, so that it is ensured that the distances between the holes are the same, the holes to be drilled can beadjusted conveniently, time and labor are saved, and the work efficiency is improved.

Owner:周鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com